410

Biodegradable nanocomposite film from sugarcane waste

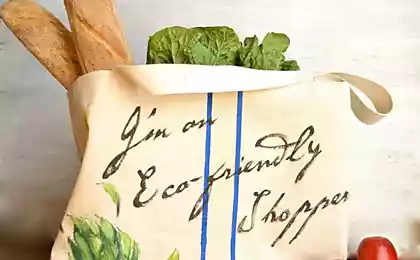

Iranian researchers from Tehran University used sugar cane waste for the production of fully-cellulose nanocomposite film (all-cellulose nanocomposite, ACNC). The product has unique physical and mechanical properties and may find many applications in packaging industry, medicine and electronic industries.

The Iranian method of production of nanofibres is easier, faster and more profitable existing methods. Reportedly, the size of nanofibers from cellulose is 26-52 nm nanocomposite film of them is able to resist tensile loads of up to 140 MPa. This strength exceeds the performance of all existing as biodegradable and not susceptible to chemical degradation of the films.

Perhaps the invention of scientists from Tehran will be able to replace the package of artificial polymers and oil products, production and use of which is accompanied by damage to the environment.

Raw material for nanofibers ACNC is the most common natural biopolymer cellulose, which can be obtained from cane waste generated in the production of sugar. Fibrous press cake remains unclaimed after crushing the stems of sugar cane and extraction of the sweet juice. Iran annually produces hundreds of thousands of tons of cane sugar, according to the lead researcher quaderi Moin (Moin Qaderi) each ton generating 280 kg of waste.

In the course of film production the cellulose fibres are separated from the pomace, cleaned and comminuted mechanically, then used to manufacture "nanobiology". The final nanocomposite product with the stated properties is obtained by partial dissolution in dimethylacetamide — lithium chloride (N,N-dimethylacetamide/lithium chloride).

The results show that with the increase of time fractional diffusion dissolving the nanocomposite in the solvent decreases as the transition of the crystalline component in an amorphous form. However, for the same reason, the reduced resistance.

The conversion of cellulose microfibers to nanofibers accompanied by an increase in the resistance of film to stretching. Researchers believe that the cause of increase of strength is a decrease in the number of "points break", which lead to the appearance of cracks in the cellulose fibers. With decreasing size increases the specific strength and integrity of the individual fibers. In addition, the smaller particles of the fibers, the film becomes more transparent.

The results of the work of scientists published in the journal Carbohydrate Polymers (Carbohydrate polymers) in January 2014.

Facepla.net according to the materials of FARS

ROPP

Source: facepla.net