457

The traditional way of warming the house with sawdust

Today, for the insulation of walls, roofs, floors, attics and others use different materials, each of which has its pros and cons. However, the good old sawdust insulation continues to enjoy popularity as the most democratic method.

Sawdust is the by — product of the timber industry. They, together with the slag and shavings to insulate the premises of even our grandfathers and great grandfathers. Although sawdust as insulation has many critics, many people continue to follow the tradition, given that the chips have established themselves as a fairly reliable material.

What to consider when winterizing?

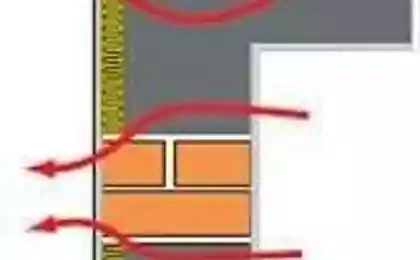

For warming does not fit the ordinary sawdust, which remained after sawing logs. The material need to be appropriately prepared. It is processed antiseptic composition, thoroughly dried and mixed with slaked lime, or lime-pushonkoj. The lime are needed for protection from mice, rats and other rodents. It should be at least 10 % of the total mass of sawdust. Pour the material on a wooden or metal shield, and mix well with a shovel. This mixture is poured into cavities of roofs, floors, etc. in a layer of 20-30 cm

No harm will eliminate the flowability of the material. Otherwise, the insulating filling may eventually settle down and start to miss the heat. To prevent this problem in the following way. The sawdust is added to lime and gypsum in a ratio of 85 % sawdust, 5 % gypsum, 10% lime. Thus, the bulk insulator is converted into a material of rigid type. Note that in this case dry sawdust is not worth it. Cook the insulation in small portions, because the gypsum sets very quickly, and the material can be hardened before installation. Instead of lime you can use lime putty, but it will need two times more gypsum replace cement.

Insulation technology

Here is the algorithm the traditional way of warming the house with sawdust.

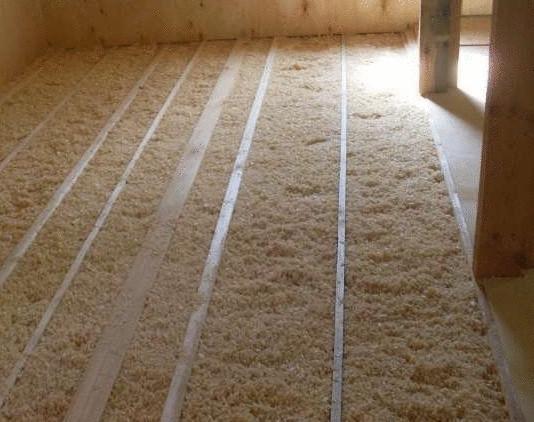

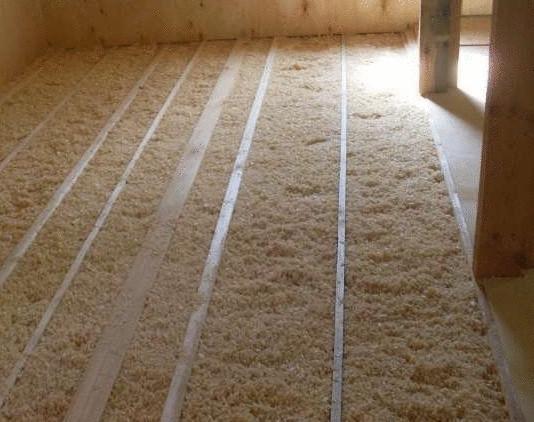

The first stage. Prepare a mixture of sawdust, plaster/cement, lime (10 buckets of sawdust, 1 part of plaster or cement, a bucket of lime). With the help of a watering can next local anesthesia is sprayed on insulator boric acid, which acts as an antiseptic. You will need 5-10 l of water. The humidity is adjustable independently. To do this, take some of the mixture and squeeze in your hand. If the lump is not scattered, the mixture is ready.

Second stage. Sawdust to use in areas that require thermal insulation, properly stamped material and leave the mixture to "ripen".

The third stage. Two weeks later, the insulator needs to be checked for the presence of voids, if any, it needs re-filling of sawdust.

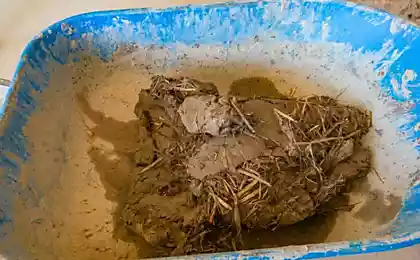

By the way, many made from sawdust warm plaster. To do this, mix sawdust with clay, cement, newsprint and water. In the result you will get plaster for interior use.

Source: www.ecology.md

Sawdust is the by — product of the timber industry. They, together with the slag and shavings to insulate the premises of even our grandfathers and great grandfathers. Although sawdust as insulation has many critics, many people continue to follow the tradition, given that the chips have established themselves as a fairly reliable material.

What to consider when winterizing?

For warming does not fit the ordinary sawdust, which remained after sawing logs. The material need to be appropriately prepared. It is processed antiseptic composition, thoroughly dried and mixed with slaked lime, or lime-pushonkoj. The lime are needed for protection from mice, rats and other rodents. It should be at least 10 % of the total mass of sawdust. Pour the material on a wooden or metal shield, and mix well with a shovel. This mixture is poured into cavities of roofs, floors, etc. in a layer of 20-30 cm

No harm will eliminate the flowability of the material. Otherwise, the insulating filling may eventually settle down and start to miss the heat. To prevent this problem in the following way. The sawdust is added to lime and gypsum in a ratio of 85 % sawdust, 5 % gypsum, 10% lime. Thus, the bulk insulator is converted into a material of rigid type. Note that in this case dry sawdust is not worth it. Cook the insulation in small portions, because the gypsum sets very quickly, and the material can be hardened before installation. Instead of lime you can use lime putty, but it will need two times more gypsum replace cement.

Insulation technology

Here is the algorithm the traditional way of warming the house with sawdust.

The first stage. Prepare a mixture of sawdust, plaster/cement, lime (10 buckets of sawdust, 1 part of plaster or cement, a bucket of lime). With the help of a watering can next local anesthesia is sprayed on insulator boric acid, which acts as an antiseptic. You will need 5-10 l of water. The humidity is adjustable independently. To do this, take some of the mixture and squeeze in your hand. If the lump is not scattered, the mixture is ready.

Second stage. Sawdust to use in areas that require thermal insulation, properly stamped material and leave the mixture to "ripen".

The third stage. Two weeks later, the insulator needs to be checked for the presence of voids, if any, it needs re-filling of sawdust.

By the way, many made from sawdust warm plaster. To do this, mix sawdust with clay, cement, newsprint and water. In the result you will get plaster for interior use.

Source: www.ecology.md