417

New polymer will help to make the transition to green energy

Spongy polymer that absorbs carbon dioxide from greenhouse gases and then releases it for further processing, will greatly facilitate the transition from fossil fuels to new, more environmentally friendly energy sources such as hydrogen. This new material was developed by a team of researchers from the University of Liverpool under the supervision of Professor Andrew Cooper.

The main advantages of polymeric materials are strength and resistance to various influences, both mechanical and thermal and chemical, excellent performance for adsorption of CO2 and relatively low production cost. Due to these properties, the adsorbent can be used in new technologies with zero emissions titled "combined cycle integrated gasification" (IGCC), which allows you to convert fossil fuels and hydrogen gas.

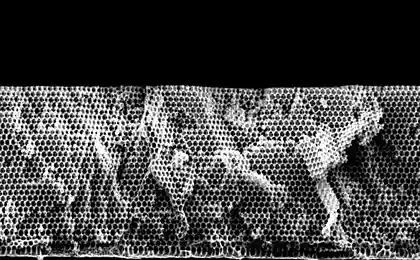

Existing today on the market of carbon dioxide adsorbents are most commonly used only to remove it from the exhaust chimneys in coal-fired power plants. In contrast, the new material, developed by Cooper and his team, has a microporous structure which acts as a sponge for dishes – swells, absorbing carbon dioxide, and then, when squeezed, releases it. According to the researchers, "sponge" CO2 works better at high pressure, which usually occur in the gasification processes.

The material, in appearance resembling sand brown color, is produced by compounds in the crystalline structure of many small molecules based on carbon. A similar structure is polystyrene, the plastic used in the production of Styrofoam and other packing material. Like polystyrene, the new adsorbent has a high stability even in aggressive environments, for example, keeping the process of boiling in acid. Adsorbing carbon dioxide, the material does not absorb water vapor, which is one of the reasons for the decline in efficiency of other counterparts in the market. And finally, this microporous polymer is reusable and has a fairly long service life.

Currently, Cooper is planning to adapt the material for use in chimneys and other exhaust, possibly in conjunction with the existing membranes, trapping carbon dioxide.

Source: www.cheburek.net