419

Japanese scientists have created a new universal 3D bio-printer

Ten million eight hundred ninety three thousand six hundred four

In the world of medicine has already conducted several operations to replace the joints of these new, synthetic, created through 3D printing, however, that any comparison is not with the possibility artificial creation of these bones or organs. However, thanks to Japanese experts, the wait for such a possibility we may need much less time than previously thought.

Previous the most optimistic forecasts in the field of bioengineering talked about the fact that to achieve the level of technology that would allow mass manufacturing and use of new human tissue, will require at least several years. Japanese scientists, in turn, are more optimistic believe that produce new bone on the basis of 3D printing technology we will be able in the near future. At least on an experimental basis.

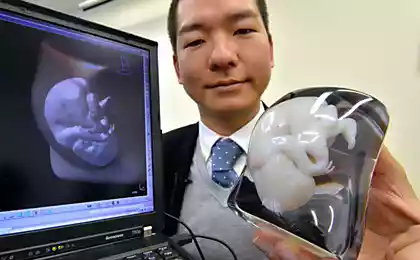

A group of researchers under the leadership Taeshi Takato, Professor of the University hospital of Tokyo, has created a new universal 3D bio-printer that allows the order to produce not only bone but also cartilage, joints and skin. To create new connection uses a synthetic substance similar in structure to human collagen (a protein that is the basis of all connective tissues of our body) and stem cells.

The design of the new implant is based on data from computer tomography of the patient. In this case, it is impossible to create a new organ or tissue that will most effectively be able to settle down inside the body and grow together with living tissues. An important role in the production of new tissue plays the use of biological agents. However, more important is the role of stem cells, as they allow you to grow based on them practically on any part of the body.

It would be interesting to note the source from which the artificial protein (collagen mimic). It was invented by a company that experiments were tried to see if we can use the stuff with the structure of collagen for the production of... film.

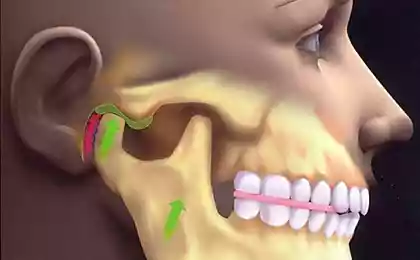

One of the major advantages of implants, created on the basis of new materials, is that when you want to use them for the children they create through time, no problems. Ordinary synthetic joints and bones have to constantly replace. By the way, that is why many people refuse the implant, although in some cases, when the pain or inability to perform even simple daily tasks become unbearable and impossible implant placement is the only alternative.

In turn, the new biointegrated implants after installation become an integral part of the body or in the end will eventually be replaced by natural tissue that will grow along with the body as usual. Thanks to the new created bio-printer, scientists have the possibility to produce artificial bones with incredible accuracy up to 100 microns (0.1 mm).

Source: hi-news.ru

In the world of medicine has already conducted several operations to replace the joints of these new, synthetic, created through 3D printing, however, that any comparison is not with the possibility artificial creation of these bones or organs. However, thanks to Japanese experts, the wait for such a possibility we may need much less time than previously thought.

Previous the most optimistic forecasts in the field of bioengineering talked about the fact that to achieve the level of technology that would allow mass manufacturing and use of new human tissue, will require at least several years. Japanese scientists, in turn, are more optimistic believe that produce new bone on the basis of 3D printing technology we will be able in the near future. At least on an experimental basis.

A group of researchers under the leadership Taeshi Takato, Professor of the University hospital of Tokyo, has created a new universal 3D bio-printer that allows the order to produce not only bone but also cartilage, joints and skin. To create new connection uses a synthetic substance similar in structure to human collagen (a protein that is the basis of all connective tissues of our body) and stem cells.

The design of the new implant is based on data from computer tomography of the patient. In this case, it is impossible to create a new organ or tissue that will most effectively be able to settle down inside the body and grow together with living tissues. An important role in the production of new tissue plays the use of biological agents. However, more important is the role of stem cells, as they allow you to grow based on them practically on any part of the body.

It would be interesting to note the source from which the artificial protein (collagen mimic). It was invented by a company that experiments were tried to see if we can use the stuff with the structure of collagen for the production of... film.

One of the major advantages of implants, created on the basis of new materials, is that when you want to use them for the children they create through time, no problems. Ordinary synthetic joints and bones have to constantly replace. By the way, that is why many people refuse the implant, although in some cases, when the pain or inability to perform even simple daily tasks become unbearable and impossible implant placement is the only alternative.

In turn, the new biointegrated implants after installation become an integral part of the body or in the end will eventually be replaced by natural tissue that will grow along with the body as usual. Thanks to the new created bio-printer, scientists have the possibility to produce artificial bones with incredible accuracy up to 100 microns (0.1 mm).

Source: hi-news.ru