411

"The nose" helped to increase the efficiency of wind turbines

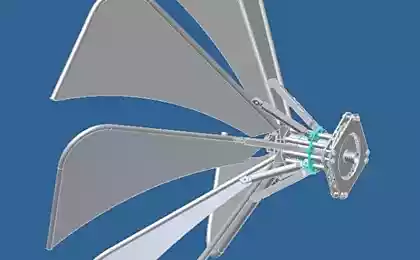

The nose cone can be installed on existing wind turbines, increasing the production of their electricity. General Electric is experiencing in California a new type of wind turbine. The Central portion of its large blades closed convex cone, and 90-meter tower is not solid, as its competitors, but consists of steel trusses, covered with polyester coating. About the new tells GE Reports.

Technology, where her windmill uses a dome-shaped Radome, the company called the ecoROTR. Wind turbines of this type tested with GE in may this year on the outskirts of the Mojave desert. While its operation confirms the findings of earlier wind tunnel: a wind turbine with a nominal capacity of 1.7 MW produces 3% more energy than its counterparts without such a fairing.

Domed 18-foot 900-pound head made of aluminium, does not allow the wind to pass through the blades in the center, where it least contributes to the promotion of the rotor. Flowing around it on all sides, the wind gets more distant from the center portion of the blade. As explained in GE, from the point of view of the mechanics of the blade are a variety of levers. The more short arm uses a lever, the harder it is to spin the rotor.

The growth of power generation of the wind turbine of 3% may seem small, but today the U.S. is already 5% of all the electricity produced by such facilities, say the developers. Therefore, the application of the new fairing at all American wind power plants would increase power generation by more than 6 billion kilowatt-hours per year.

In addition to equipping existing turbines, fairings can be installed on new wind turbines, where their use promises great returns. The Central portion of the blade that covers a blister, now in fact not working. However, if the blades of the future wind turbines will begin to mount right to it, this will allow you to extend the working length of the blades and increase sweeping their area.

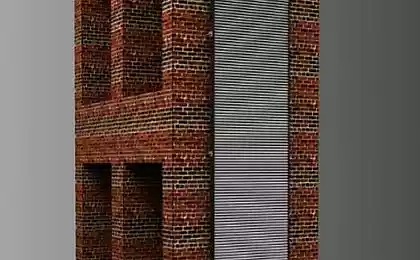

View of new tower from the inside; the rejection of solid design has significantly reduced its weight and substantially increase the width and stability of the structure

From 135 metres total height of the experimental wind turbine is 90 meters gives a tower, also made of new technology. Today, the steel towers of wind turbines perform whole, and to make them wider than 4.5 meters does not allow for the possibility of roads and bridges for General use. Meanwhile, the optimal width of the tower, based on the requirements of its sustainability — 9-10 meters.

To resolve this contradiction, GE engineers designed the tower, assembled from steel trusses. After the alignment of the gaps between farms, able to produce reduce the efficiency of the wind turbine turbulence, close woven material based on polyester. The use of such designs will allow you to raise the height of the towers of the wind turbines, increasing their productivity, but in recent years has slowed due to the above-described difficulties with transportation of wide towers.

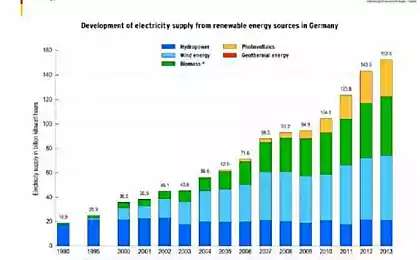

Currently, wind energy worldwide continues to grow rapidly. In 2014, its capacity reached 370 GW. Just last year was introduced 51 GW of new wind power, leader in this regard were China (over 22 GW), in second place was Germany, the third — USA. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: nplus1.ru/news/2015/06/10/narizeolico

Technology, where her windmill uses a dome-shaped Radome, the company called the ecoROTR. Wind turbines of this type tested with GE in may this year on the outskirts of the Mojave desert. While its operation confirms the findings of earlier wind tunnel: a wind turbine with a nominal capacity of 1.7 MW produces 3% more energy than its counterparts without such a fairing.

Domed 18-foot 900-pound head made of aluminium, does not allow the wind to pass through the blades in the center, where it least contributes to the promotion of the rotor. Flowing around it on all sides, the wind gets more distant from the center portion of the blade. As explained in GE, from the point of view of the mechanics of the blade are a variety of levers. The more short arm uses a lever, the harder it is to spin the rotor.

The growth of power generation of the wind turbine of 3% may seem small, but today the U.S. is already 5% of all the electricity produced by such facilities, say the developers. Therefore, the application of the new fairing at all American wind power plants would increase power generation by more than 6 billion kilowatt-hours per year.

In addition to equipping existing turbines, fairings can be installed on new wind turbines, where their use promises great returns. The Central portion of the blade that covers a blister, now in fact not working. However, if the blades of the future wind turbines will begin to mount right to it, this will allow you to extend the working length of the blades and increase sweeping their area.

View of new tower from the inside; the rejection of solid design has significantly reduced its weight and substantially increase the width and stability of the structure

From 135 metres total height of the experimental wind turbine is 90 meters gives a tower, also made of new technology. Today, the steel towers of wind turbines perform whole, and to make them wider than 4.5 meters does not allow for the possibility of roads and bridges for General use. Meanwhile, the optimal width of the tower, based on the requirements of its sustainability — 9-10 meters.

To resolve this contradiction, GE engineers designed the tower, assembled from steel trusses. After the alignment of the gaps between farms, able to produce reduce the efficiency of the wind turbine turbulence, close woven material based on polyester. The use of such designs will allow you to raise the height of the towers of the wind turbines, increasing their productivity, but in recent years has slowed due to the above-described difficulties with transportation of wide towers.

Currently, wind energy worldwide continues to grow rapidly. In 2014, its capacity reached 370 GW. Just last year was introduced 51 GW of new wind power, leader in this regard were China (over 22 GW), in second place was Germany, the third — USA. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: nplus1.ru/news/2015/06/10/narizeolico

Mad money: 35 quadrillion for $1

Conventional products instead of pesticides in Your vegetable garden