559

New wind turbines will spare birds

Introduction Aeolian energy on a large scale will lead to a sharp reduction in the number of birds of a number of types, reports Kompyulenta. But large predatory birds can and do stay only in regions where there are no wind turbines. The developers of the American company Sigma Design intend to overcome this problem with the new verolanuova turbines.

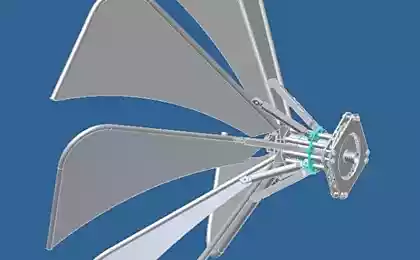

To avoid massive loss of flyers will be possible as long as Aeolian wind power is the blades. Some of them and decided to opt-in Sigma Design. The presented development is not a wind turbine in the sense which we put in a word. It is rather a Catching Wind Power device (petroulias device, CWP-device), as the manufacturer calls them. A more detailed version of the name — closed wind turbine operating on compressed air. The main developer of the new 89-year-old Raymond green.

"Conventional three-blade turbine, — says Mr. green, has already patented a new type of wind turbine, — bring down the birds from heaven because the birds can't see the massive rotating blades, moving at speeds from 128 to 304 km/h." Therefore, a new windmill is simply devoid of moving external parts. The blades are mounted behind the cone-scoop cone and internal compression, making them unavailable to birds. "In addition, our turbines almost never make noise," explains the engineer.

But that's not all the theoretical advantages of the new design. The use of cone-shaped constriction in front of the turbine increases the wind speed in comparison with the atmospheric, and the turbine can start with a negligible flow velocity from 2 m/s, which is significantly better than conventional horizontal wind turbines, and very close to vertical wind turbines. Usually with a significant speed wind turbine need to lock, otherwise it will collapse.

For small diameter turbine it like a turbojet engine, can operate at much higher wind speeds without the threat of breakage, because the ends of its lobes much shorter than the huge blades of conventional wind turbines. In short, disable the cone CWP-turbine would only need if indeed the Gale-force wind.

And, perhaps most importantly. The cone, creating a high pressure before the turbine, can be easy (for large diameters — even inflatable) and durable. But it won't be expensive, and the size of the turbine receiving energy from the wind, drastically reduced: after all, she doesn't need to have huge area metania. Meanwhile, it is the wind turbine with its moving parts and high requirements for long-term durability is the most expensive component of a windmill — and often require replacement. The new turbine, according to engineers, will be much cheaper per kilowatt-hour installed capacity, which, perhaps, will help them implementing even more environmental benefits of the design together.

In addition, because of the effect of increasing wind speed in the cone such turbines will be functional at low altitude, very close to the earth, even with minimal size and weight. For example, created by Raymond green 20-pound prototype cost $550, and the size (variable diameter from 30 to 80 cm) make it possible to install it on the roof of a conventional car, or on a small pleasure boat, not to mention the detached low-rise houses. Contribute a small version of the wind energy will be low level noise from the device.

A new type of turbine can be installed on existing masts in the replacement of worn horizontal turbines, a resource which usually does not exceed 30 years. In particular, the mass replacement of wind turbines in the area Altamont Pass (California, USA) planned for 2015, Sigma Design is seen as the preferred project in which the generators of the new type will be very helpful.

Source: /users/104

To avoid massive loss of flyers will be possible as long as Aeolian wind power is the blades. Some of them and decided to opt-in Sigma Design. The presented development is not a wind turbine in the sense which we put in a word. It is rather a Catching Wind Power device (petroulias device, CWP-device), as the manufacturer calls them. A more detailed version of the name — closed wind turbine operating on compressed air. The main developer of the new 89-year-old Raymond green.

"Conventional three-blade turbine, — says Mr. green, has already patented a new type of wind turbine, — bring down the birds from heaven because the birds can't see the massive rotating blades, moving at speeds from 128 to 304 km/h." Therefore, a new windmill is simply devoid of moving external parts. The blades are mounted behind the cone-scoop cone and internal compression, making them unavailable to birds. "In addition, our turbines almost never make noise," explains the engineer.

But that's not all the theoretical advantages of the new design. The use of cone-shaped constriction in front of the turbine increases the wind speed in comparison with the atmospheric, and the turbine can start with a negligible flow velocity from 2 m/s, which is significantly better than conventional horizontal wind turbines, and very close to vertical wind turbines. Usually with a significant speed wind turbine need to lock, otherwise it will collapse.

For small diameter turbine it like a turbojet engine, can operate at much higher wind speeds without the threat of breakage, because the ends of its lobes much shorter than the huge blades of conventional wind turbines. In short, disable the cone CWP-turbine would only need if indeed the Gale-force wind.

And, perhaps most importantly. The cone, creating a high pressure before the turbine, can be easy (for large diameters — even inflatable) and durable. But it won't be expensive, and the size of the turbine receiving energy from the wind, drastically reduced: after all, she doesn't need to have huge area metania. Meanwhile, it is the wind turbine with its moving parts and high requirements for long-term durability is the most expensive component of a windmill — and often require replacement. The new turbine, according to engineers, will be much cheaper per kilowatt-hour installed capacity, which, perhaps, will help them implementing even more environmental benefits of the design together.

In addition, because of the effect of increasing wind speed in the cone such turbines will be functional at low altitude, very close to the earth, even with minimal size and weight. For example, created by Raymond green 20-pound prototype cost $550, and the size (variable diameter from 30 to 80 cm) make it possible to install it on the roof of a conventional car, or on a small pleasure boat, not to mention the detached low-rise houses. Contribute a small version of the wind energy will be low level noise from the device.

A new type of turbine can be installed on existing masts in the replacement of worn horizontal turbines, a resource which usually does not exceed 30 years. In particular, the mass replacement of wind turbines in the area Altamont Pass (California, USA) planned for 2015, Sigma Design is seen as the preferred project in which the generators of the new type will be very helpful.

Source: /users/104