1196

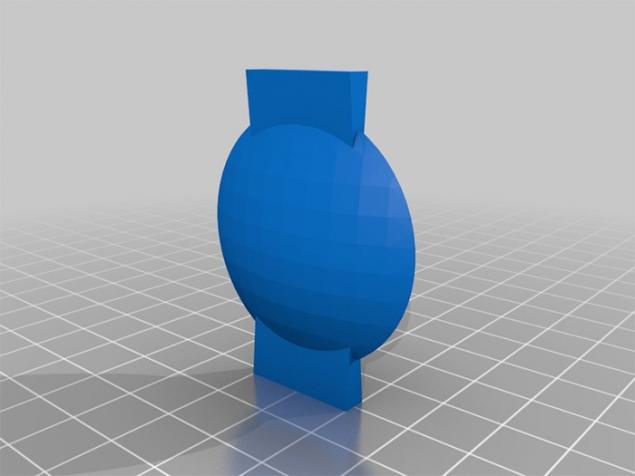

3D-press lenses for glasses and head-mounted display

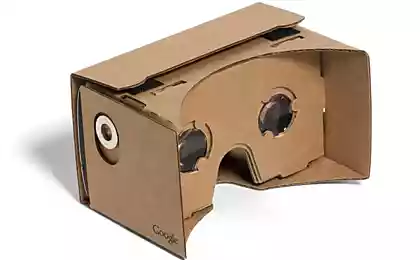

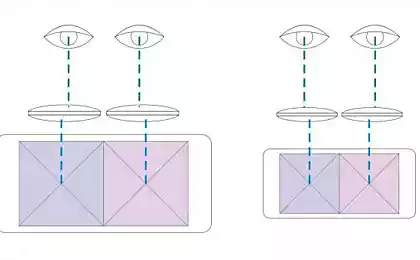

Recently, a huge popular gadgets for immersion in virtual reality, such as Google Cardboard, Oculus Rift, and others. In the case of Google Cardboard and its analogues general design is very simple, it can be assembled virtually from scrap materials. You only need a smartphone with a corresponding application. All the rest - it's a cardboard "box" on the head with fixed lenses. Screen Smartphone is divided into two parts, each eye is looking through the lens at the half of the screen.

Cardboard, smart, eraser, magnet and a pair of Velcro - all this can be found at home. The only problem with the lenses, they hardly will find in the apartment. American engineer Florian Maurer (Florian Maurer) has decided to correct this deficiency - and попытался print such lenses for iPhone 6 Plus is alone on 3D-printer.

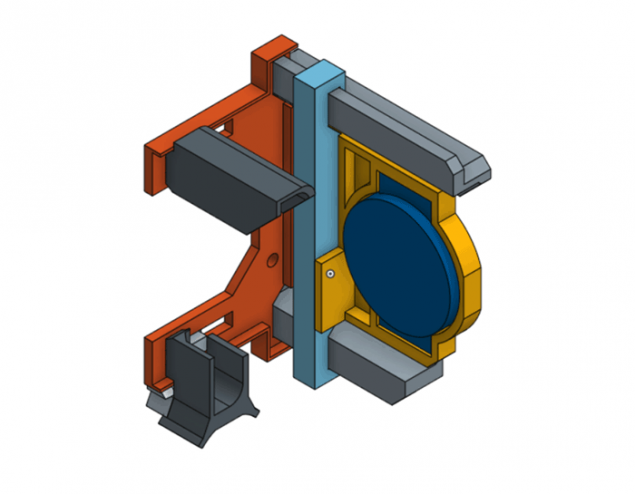

First published Florian frame for glasses, changing CAD-model editor Onshape.com. Lenses were molded from a transparent rubber, and in subsequent experiments - printed. The surface polishing grit sandpaper P220-7000 and further polished. The author acknowledges that the process is quite tedious and painstaking. Get a clear transparent optics incredibly difficult. However, for the first try 3D-printing lens on a commercially available printer receives very good.

Florian Maurer compared his work (home-made lens + iPhone) to the quality of the picture in the head-mounted display Oculus Dev Kit - and was pleased with the result.

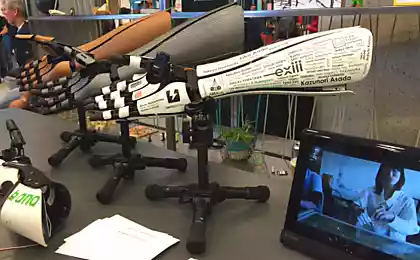

So, it all starts with the printing lens mount. Selected first model allows to independently adjust each lens, adjusting its position relative to the eye. This means that the mounting becomes quite versatile.

Attaching the head is not provided, but to test, you can do so by holding a smartphone with two hands.

To protect against noise exposure eyepieces lightly pressed against the face. However, actively move your head in this case is not very convenient.

Lenses h3>

The most interesting - how to make lenses. For example, Google Cardboard recommend such lenses for eight dollars 25 mm in diameter with a focal length of 40 mm. They take a sample to start.

Create CAD-model again helped editor OnShape.com, is the result .

Used for the manufacture of special rubber OOMOO 30 , which is poured into the mold.

Then the endless grinding and polishing by hand. Even compared with the inferior mass-produced home-made lenses are not well focused, and image blur. But this is the first experience. The author says that the effect of presence in a virtual reality still persists. While focusing on individual objects hard, but VR is not too important, especially during movement. It was obvious that the only problem - for better sanding.

Florian drew lessons from their mistakes on the first prototype - and literally 30 minutes made a second version of the attachment is much better quality. It is a simple and lightweight, and the lens moves closer to each other or are pushed further.

It has been used here Florian 3D-press lens and tried to grind them not by hand, and using the drill with sandpaper. Unfortunately, he has not found a way to avoid unacceptable funnel in the center of the lens. The author says that studied the episode show "How is this done" on channel Discovery, dedicated to the production of conventional glasses to improve vision (video below) - and I suspect that in the manufacturing process must somehow be rotated at the same time the very lens and abrasive to avoid the center of the funnel.

Apparently, 3D-printing in the future will allow yourself to make lenses for glasses virtual reality for ordinary glasses, improve eyesight. Shackle for such glasses and frames of individual form, in principle, you can print now.

Source: geektimes.ru/post/265478/

One of the world's first personal computers for sale

Xiaomi mi band with a heart rate monitor will start selling in 2 days