1016

How does sudopodёmnik

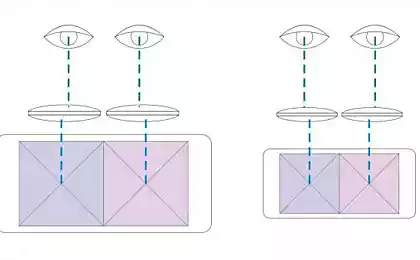

Sudopodёmnik consists of the outer harbor, the bottom of the approach channel, the actual lift and turntable. The lift is a platform movable along the track, a track width of 9 m and having a toothing. Each of the rail track is based on a separate rack. The movement is carried out by means of electric drive.

In 2011, JSC "RusHydro" start the second stage of the restoration of the Sayano-Shushenskaya hydroelectric power station, in which the station in the engine room will be set ten new hydroelectric units. June 17, 2011 the first batch of heavy large-sized units for the hydropower units SSHHPP was immersed in St. Petersburg. This three runners of hydraulic turbines, three maslovanny thrust bearing and rotor cores. A total of 537 tonnes.

Cargo followed the Ladoga and Onega lakes, through the White Sea-Baltic Canal came into the White Sea, and then, breaking the Northern Sea Route, reached the Yenisei. Reaching the Krasnoyarsk river port city in equipment was overloaded on a river barge, which was necessary to overcome the ship lift the Krasnoyarsk hydroelectric power station.

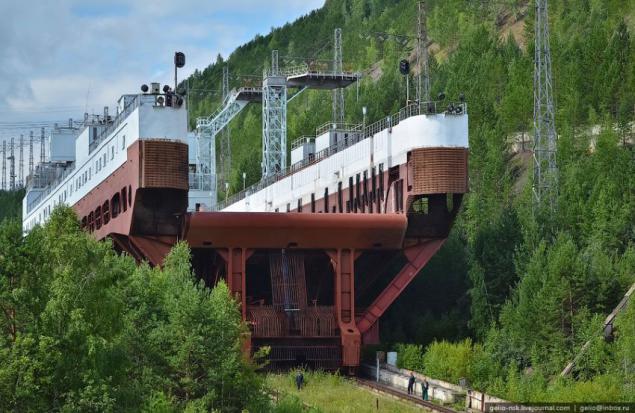

Construction of the Krasnoyarsk ship lift began in 1963. It was caused by the need to restore navigation on the Yenisei, terminated with the construction of a dam in the river bed of the Krasnoyarsk hydroelectric power station.

Officially, the ship lift was put into operation in 1982.

Developer sudopodёmnika - Lengidroproekt, manufacturer - Lengidrostal.

Ship lift is a platform movable along the track, a track width of 9 meters (this is the most extensive in the world track) and having a toothing.

The movement is carried out by means of electric drive.

120 thousand rubles is to smuggle a cargo ship lift at Krasnoyarsk.

For loading the vessel in tow, the platform is lowered below the water level.

Ship-transports camera ships with cargo capacity of up to 1500 m., With dimensions 78h15 m. And draft 1, 9 meters.

Airlock itself has dimensions 88h17 m.

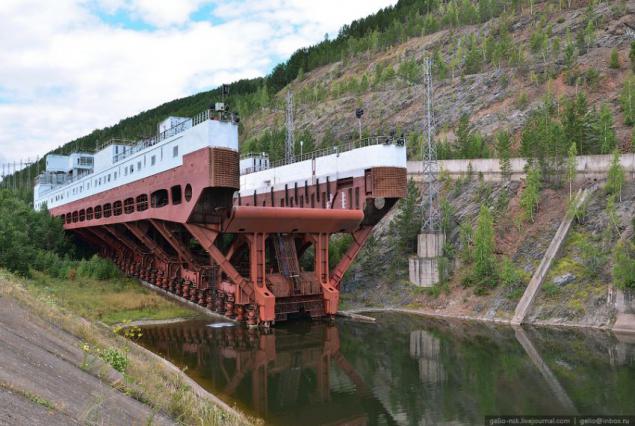

Tug Turns barge with a cargo ship-lock chamber.

Lock chamber is closed.

And the platform begins to move up the overpass. The barge is transported inside "afloat».

Ship-way of the downstream

Managing movement and ship-camera systems is carried out from a control panel located in the front superstructure.

Tractive force to move the camera on the ship-paths are created using 156 radial piston sudomotorov power up to 75 kW at a rate of 1 turn - 16 l.

The speed of movement of the ship inclined paths of 20m / min or 1, 2 km / h

Weight ship-camera with the water level in the receiving basin 2, 2 m - 8100 m.

Rotator is designed to transfer from one ship-chamber pond to another, or to repair the installation site.

PTZ control is carried out from a control panel located inside the beam.

The length of the rotary device - 104, 6 m.

The peripheral speed of rotation of the radius circular paths - 20 m / min

The barge with equipment for SSHHPP safely delivered to the water area of the Krasnoyarsk reservoir, where it took two river tugs - "BT-312" and "Chunoyar." From here they took her up the river to Mainskaya HPP. THERE equipment will be handled in a special road transport, which will take units of hydroelectric generators at the installation site power plant.

Source: gelio.livejournal.com