1807

Ingenious method of making elastic conductors using a sewing machine

Today it is difficult to imagine a scientist or engineer who does not use in complex and expensive equipment and exotic materials that are not available to mere mortals. Yet sometimes spectacular results achieved with the simplest means. So, Geim and Novoselov were awarded the Nobel Prize for his studies of the properties of graphene, which they prepared by a conventional adhesive tape repeatedly exfoliating grains of graphite tape - this method is still widely used in laboratories around the world. Recently, it was discovered that graphene can be produced from a suspension of graphite using household blender and dishwashing liquid. Or, for example, a method of manufacturing artificial "muscles» from the usual fishing line .

As soon as the components of computers are becoming slimmer, everything looks realistic prospect of a "smart clothes", medical equipment, prosthetics, implants with integrated sensors and processors. The proximity of these items to the human body dictates the need to make them soft and supple. Electronics is a big problem, because the computers are made from silicon and metal. One side of this issue - the creation of flexible wires connecting components. There are different options - up to the polymer capillaries, filled with liquid metal . At Purdue University, which is the traditional "source of manpower" aerospace industry in the USA, have developed a технологию creating elastic conductors using the sewing machine, thin copper winding wire, thread PVA and silicone.

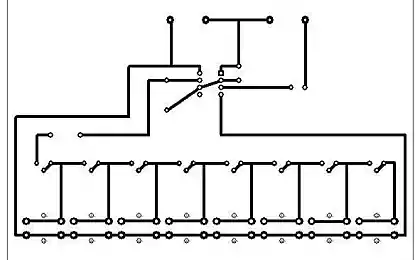

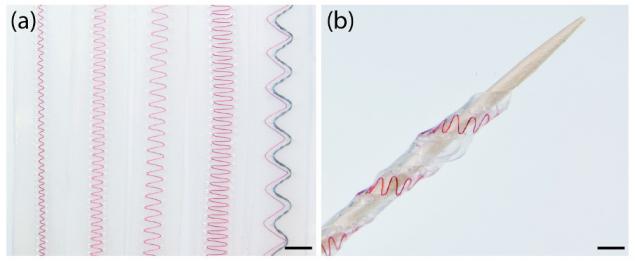

The essence of the method is very simple - taken polyethylene base and on it is a zigzag stitch - is able to almost any sewing machines. As you know, the machine sew two threads - one at the top and threaded the needle, and the other is fed from the bottom and is intertwined with the first, forming a seam. In the upper thread was taken soluble thread PVA , which can be bought in the fishing shop, and as the bottom - a thin copper wire winding. Thus, the conductor turned out to be neatly stacked zigzag and is fixed on a polyethylene film. Thereafter, the film from the conductor filled silicone Ecoflex, and after curing for several hours thread PVA dissolved in the water was removed and a polyethylene backbone.

The end result - a thin and elastic silicone tape with the conductor inside. Silicone quite reliably protects conductor and evenly distributes the load in tension. The tape can withstand 120,000 cycles of tension and compression at 30% of the length 50 000 - 55% and 15 000 - 110%. Limit the increase in length at maximum dense zigzag can reach 500%, but the number of cycles under extreme tension decreases dramatically - wire starts to break at the bend.

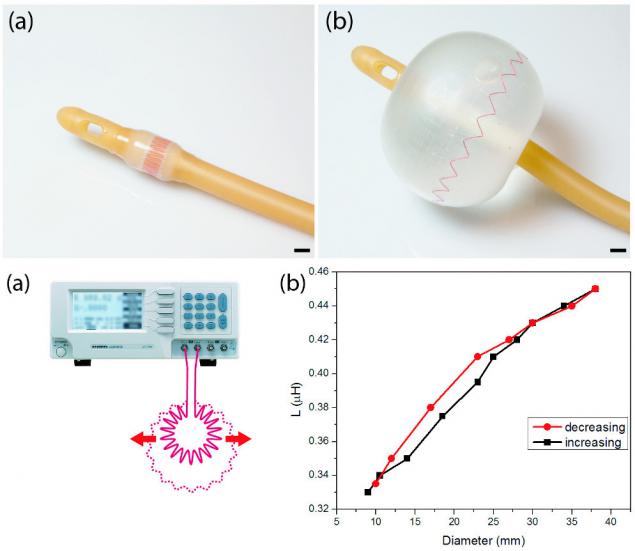

Scientists have also demonstrated the possibility of using such a flexible conductor in real medical equipment. They did a stretch sensor for Foley catheter, which is used in urology. A catheter with an inflatable rubber tube tip. The sensor allows you to control the degree of inflation of the catheter within the bladder. The principle of operation of the sensor is based on measuring the inductance of the ring conductor - it varies in proportion to the diameter of the coil.

Source: habrahabr.ru/post/225515/