1193

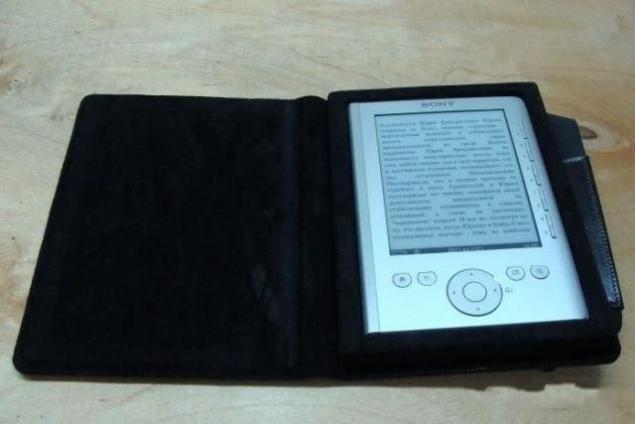

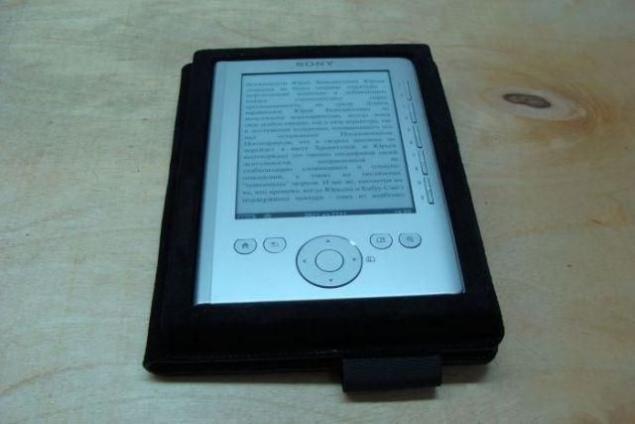

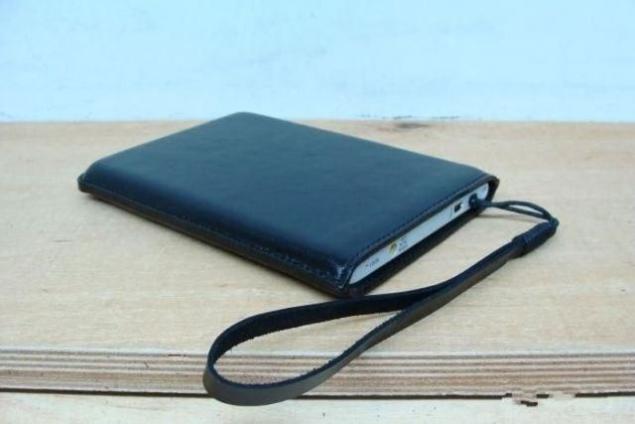

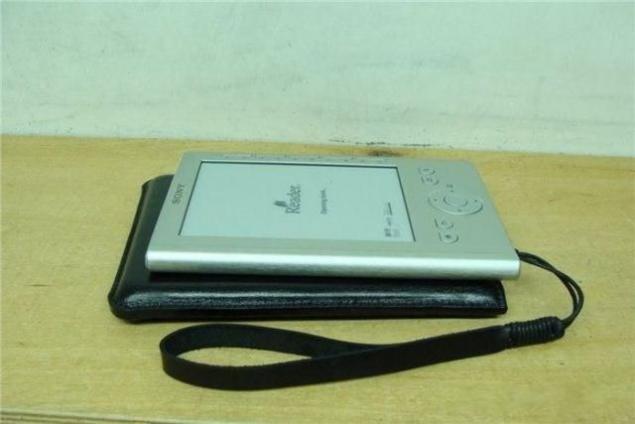

Making the Case for a tablet with their hands

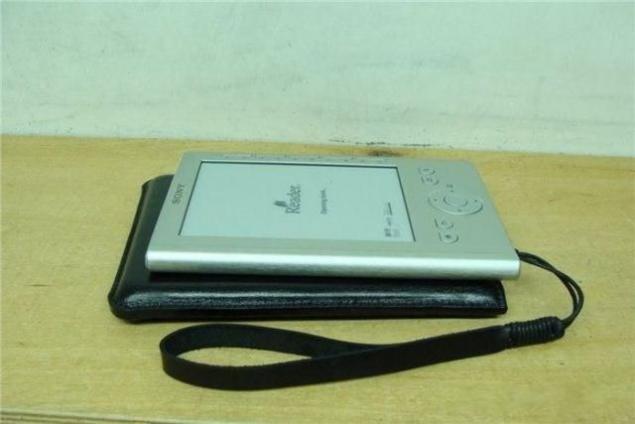

If you grow the hands of the right place, and you are too lazy to buy cover for your tablet or reader, then have a look at the continuation of the post. Further, excellent guide on how to make such a case with his own hands.

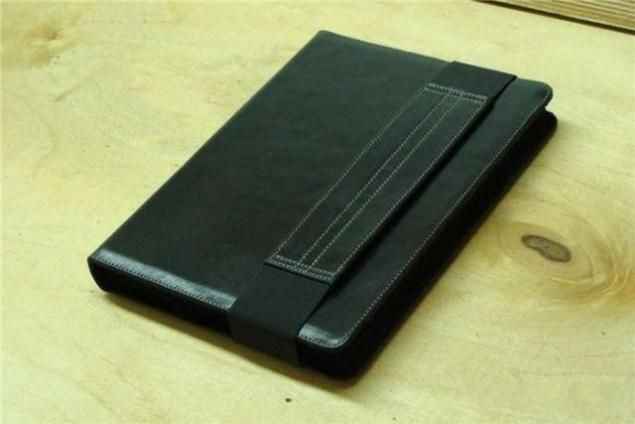

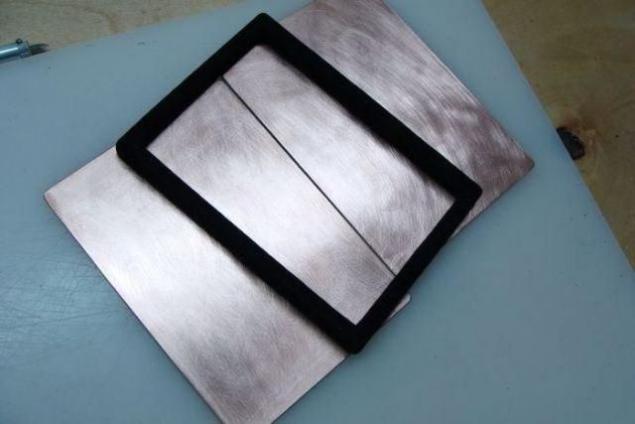

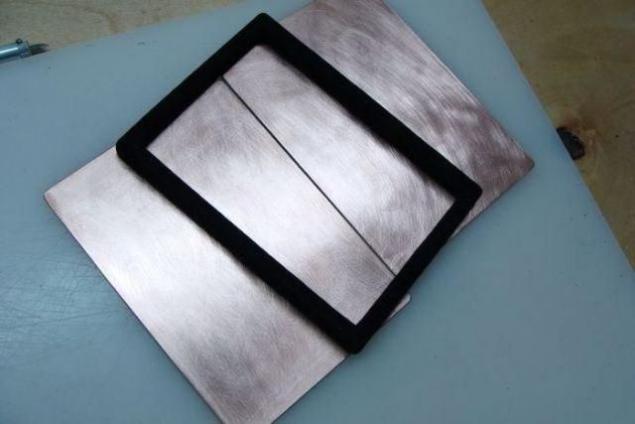

Oak frame (goes any tree), covered with suede

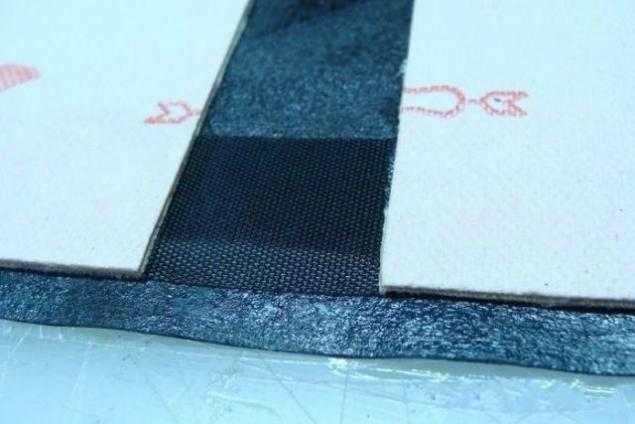

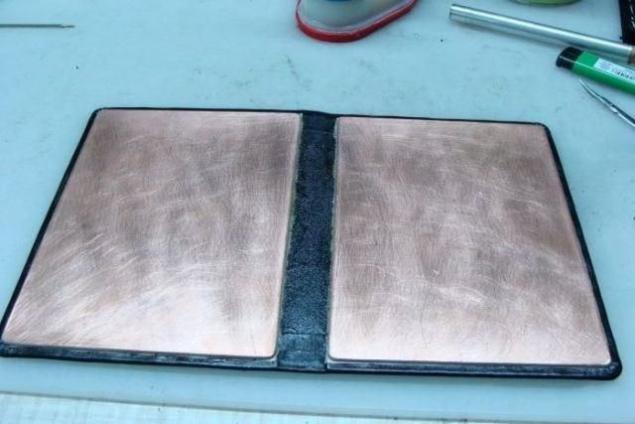

Textolite cut and stripped for better adhesion of the glue

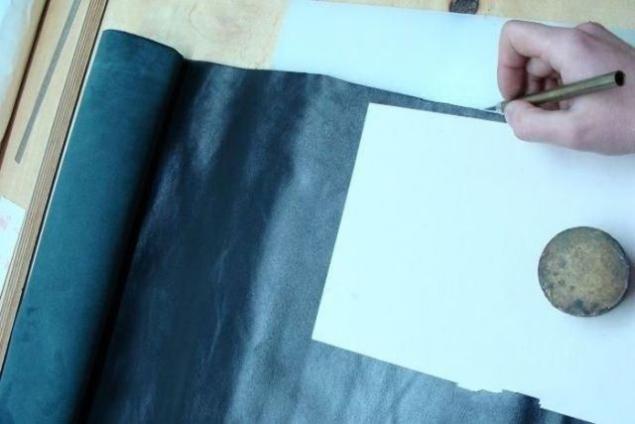

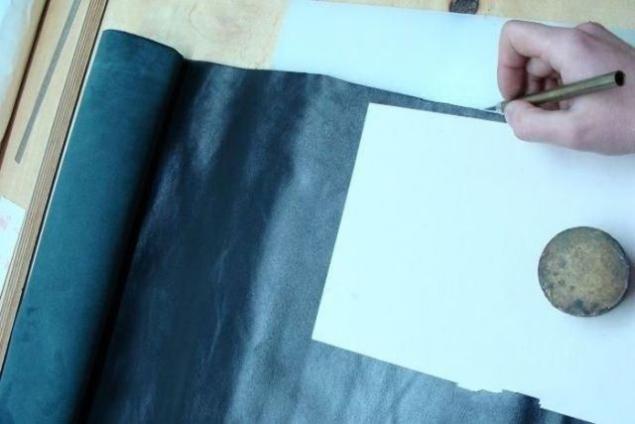

Kroim skin

Process brussovki skin (Undercut edges of the skin thickness)

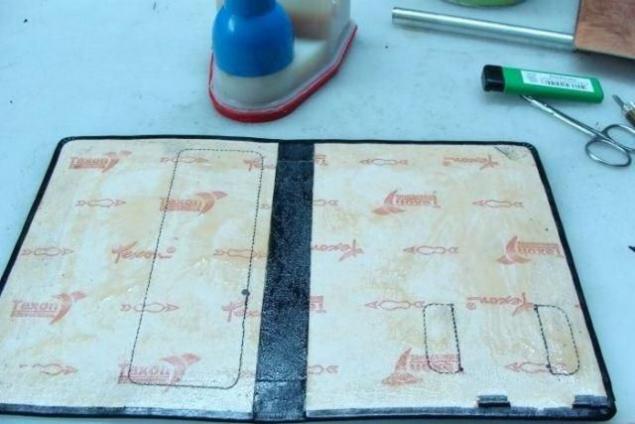

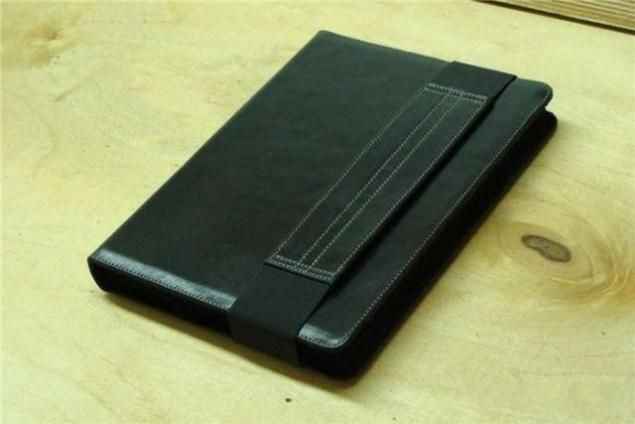

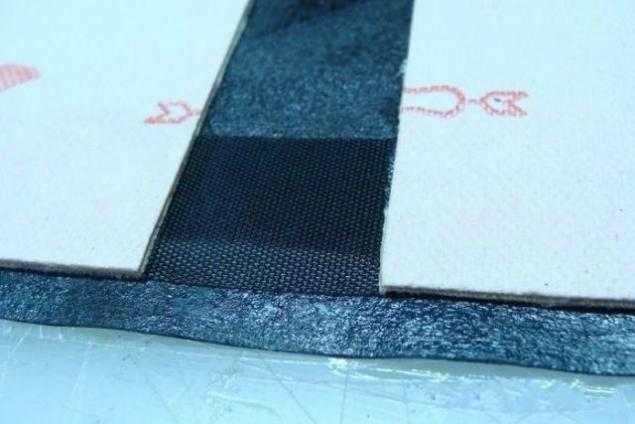

Future of the cover halves, cut from 0.8mm shoe cardboard and pasted on one side with several layers of fabric for "soft" top cover

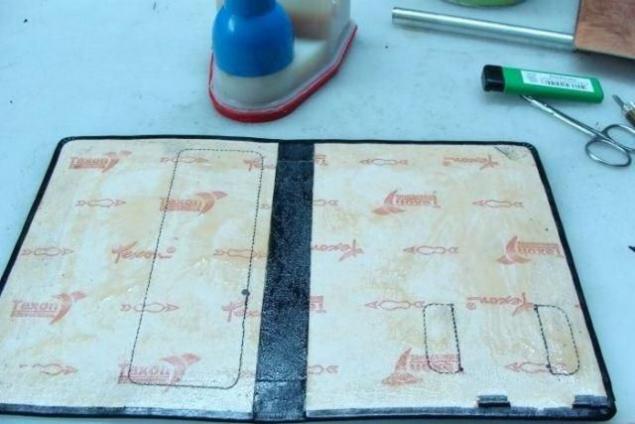

Assembling the cover of the case, sticking to the cardboard Nairit (Supercolla)

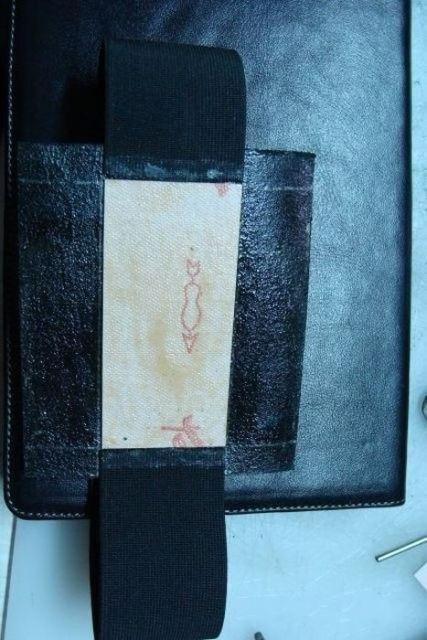

This band, which prevents the "arc" around the edges when you close the cover halves

Bending edges

Paint the visible (fixation and gum paste decorations on the front half of the cover) cut leather paint Tehnoem

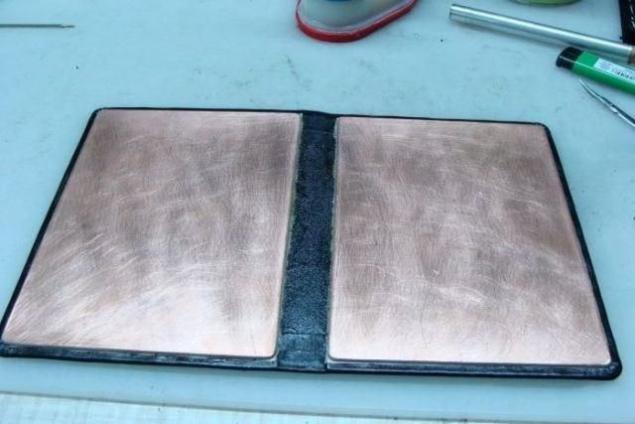

Nairit coat with cover for further gluing PCB

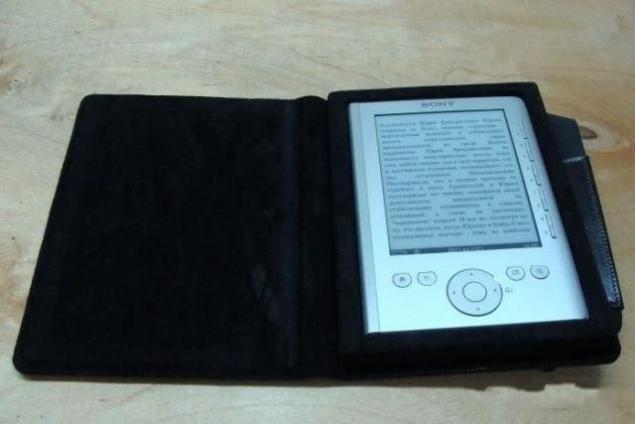

When the PCB is pasted suede (interior) with a small allowance (a technological point) and sewn around the perimeter of the cover

Then cut off the excess suede

Mark up a place in the frame

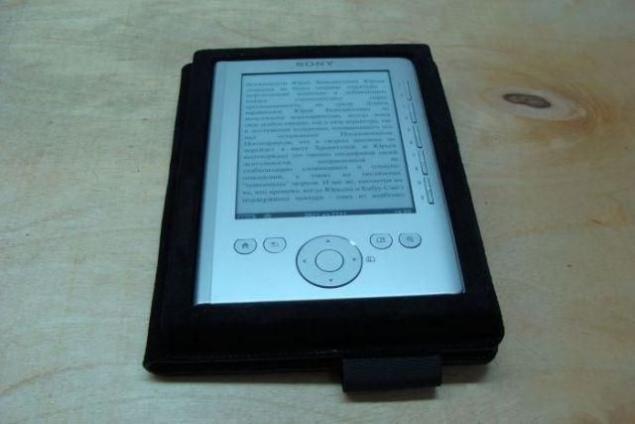

Frame, cover and liner smeared polyurethane adhesive SAR306, after drying, the adhesive is heated hairdryer and parts are glued

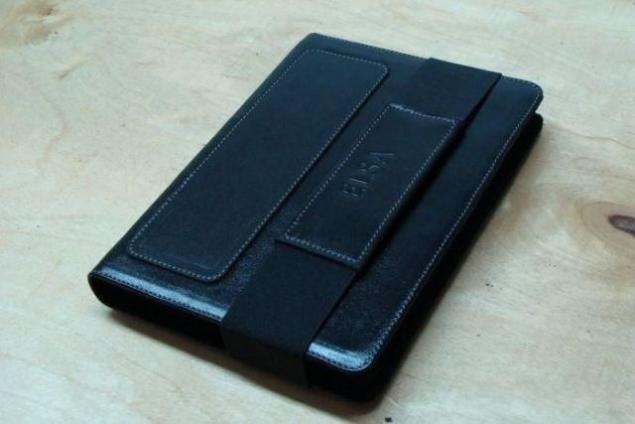

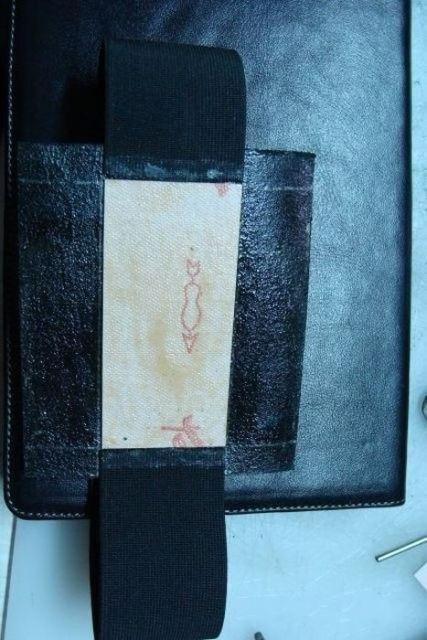

Elastic threaded in the allotted her a place on the cover. Are glued and stitched "lock" for the gum. Embossing is applied to the assembly on the special device for hot stamping

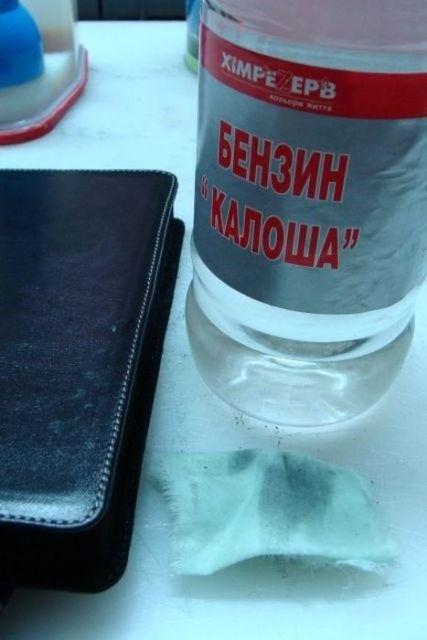

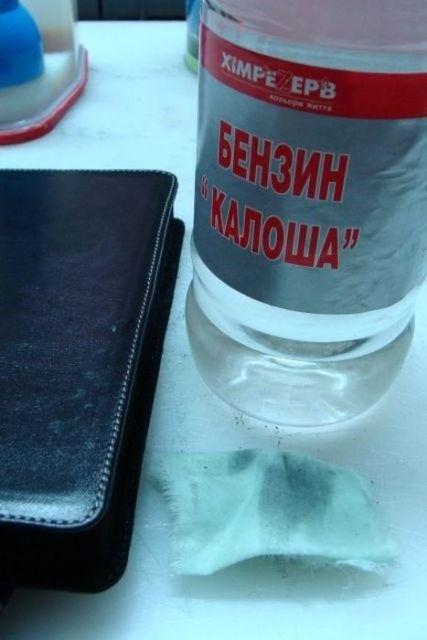

The case is cleaned with gasoline traces of pencil, glue and other dirt

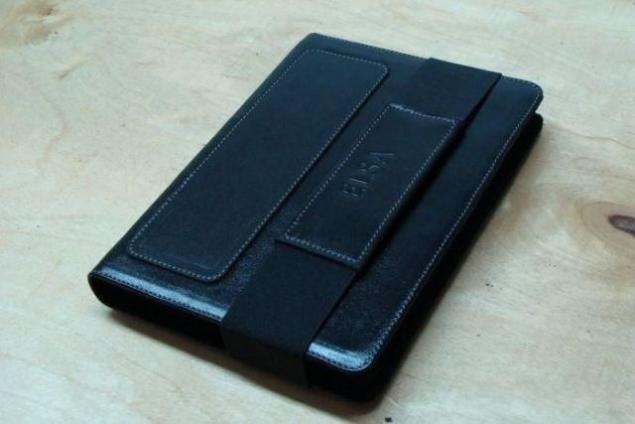

Finishing products. This crap even out skin tone and give it shine

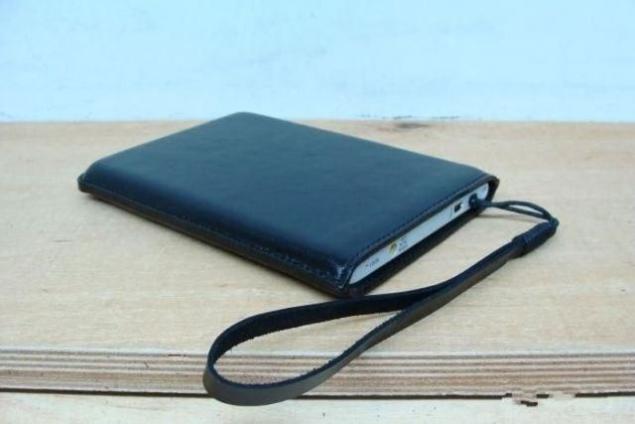

Here are a few projects on the same subject.

Oak frame (goes any tree), covered with suede

Textolite cut and stripped for better adhesion of the glue

Kroim skin

Process brussovki skin (Undercut edges of the skin thickness)

Future of the cover halves, cut from 0.8mm shoe cardboard and pasted on one side with several layers of fabric for "soft" top cover

Assembling the cover of the case, sticking to the cardboard Nairit (Supercolla)

This band, which prevents the "arc" around the edges when you close the cover halves

Bending edges

Paint the visible (fixation and gum paste decorations on the front half of the cover) cut leather paint Tehnoem

Nairit coat with cover for further gluing PCB

When the PCB is pasted suede (interior) with a small allowance (a technological point) and sewn around the perimeter of the cover

Then cut off the excess suede

Mark up a place in the frame

Frame, cover and liner smeared polyurethane adhesive SAR306, after drying, the adhesive is heated hairdryer and parts are glued

Elastic threaded in the allotted her a place on the cover. Are glued and stitched "lock" for the gum. Embossing is applied to the assembly on the special device for hot stamping

The case is cleaned with gasoline traces of pencil, glue and other dirt

Finishing products. This crap even out skin tone and give it shine

Here are a few projects on the same subject.