702

How to produce a copper wire

Copper wire to "Novgorod Metallurgical Plant" is produced from secondary copper raw material. The process is very nice and loud.

First, the plant is brought copper scrap.

Scrap all, everything that contains at least as copper, are brought for processing.

This scrap is charged here in this "gun" and begin to heat up, to get a "soup" of molten copper. Almost all foreign impurities burn.

An ultra-high temperatures, this gun special "syringe" is injected oxygen under pressure.

The temperature rises "soup" begins to boil.

Type "gun" behind.

Included are drawing and the whole mechanism starts to rotate.

The process of separation. Very unusual, when you are near.

After the separation of copper waste into factions, some of which contain copper, that such a machine goes to the next melted.

Located next to very heavy and hot.

I put the "pot" in the oven.

On the reverse side of the furnace. This is copper, but it still contains a lot of impurities.

Molten metal falls on the carousel, where bottled in shape.

Wow!

When taking these shots I fired a tripod =)

While the carousel scrolls one turn, copper alloy has time to harden.

One of the shops.

Frozen workpiece manipulator puts in a water bath for cooling.

When the workpiece close to the water, the water begins to boil.

Pschschsch!

After all these processes are obtained here are blank. As you can see, many more impurities.

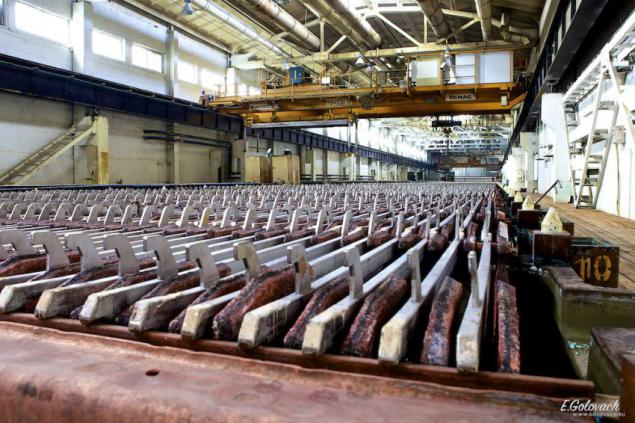

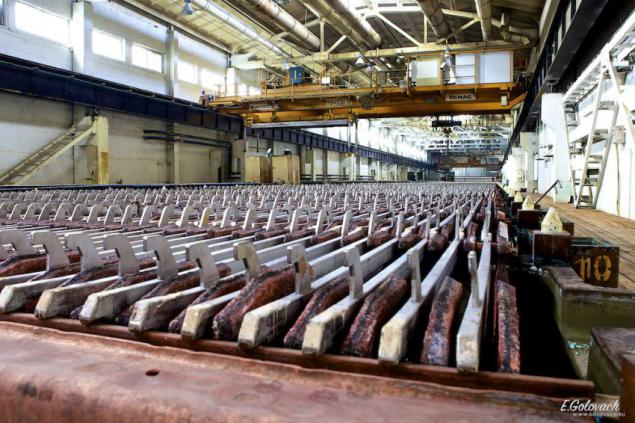

From blanks formed units and sent to the shop where the huge electrolytic bath.

Process cranes allow you to organize the cassette loading of the electrodes in an automatic mode. To handle the electrodes installed three automated lines: machine preparation of the anodes, the car and the car wash sdirki anode butt.

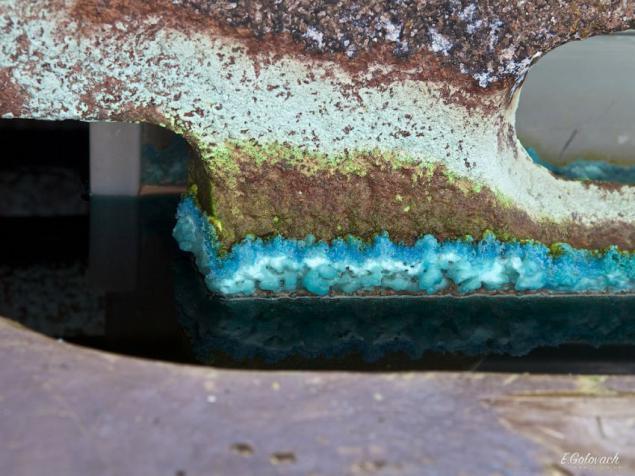

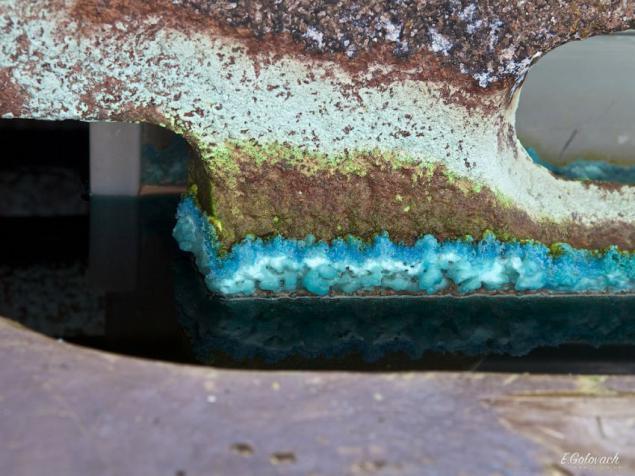

The electrolysis process is conducted with a constant circulation of the electrolyte in the electrolytic bath, in this regard, the workshop created a system of preparation of the electrolyte, preparation and dispensing of reagents, filtration solutions.

After unloading the bath cleaned from the bottom sludge, which is then extracted gold, silver, selenium, tellurium.

Unloading cassettes.

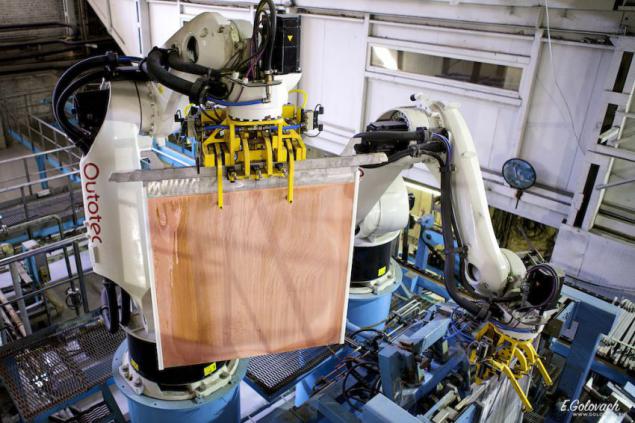

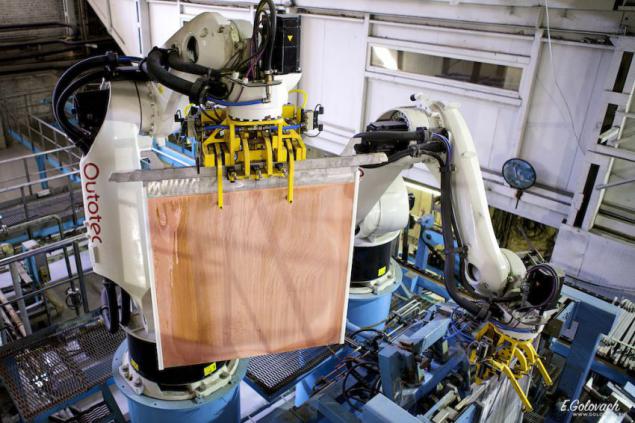

After the bath, the copper plate with a clean, sorted and placed into briquettes - Handling robots in fully automatic mode in order to send to the smelter again!

The finished raw materials.

In this workshop, have pure copper is converted to a liquid state for an extract from it wires.

The process is very beautiful.

Supportive gas burner.

The molten composition is obtained is such a blank, which is necessary to give a definite form.

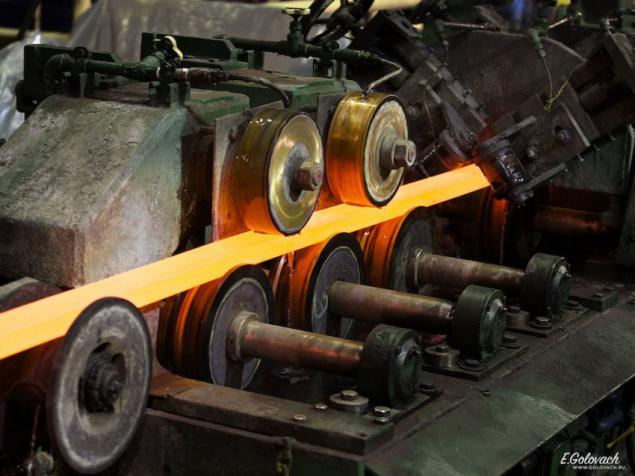

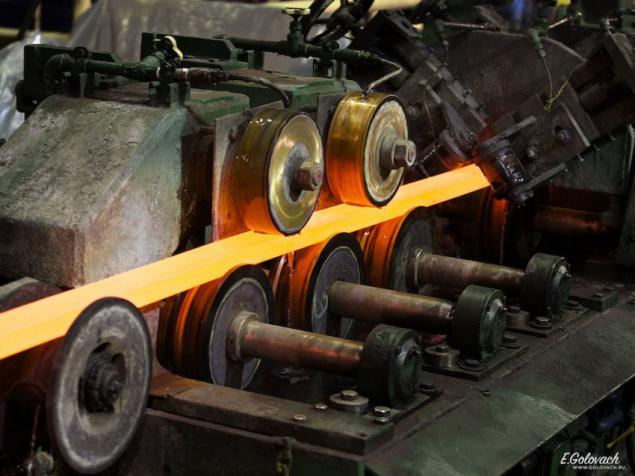

Rolling.

Cut off all unnecessary.

The mixture is cooled to a temperature and

again heated, but pulling the wire required diameter.

Source: engineering-ru.livejournal.com

First, the plant is brought copper scrap.

Scrap all, everything that contains at least as copper, are brought for processing.

This scrap is charged here in this "gun" and begin to heat up, to get a "soup" of molten copper. Almost all foreign impurities burn.

An ultra-high temperatures, this gun special "syringe" is injected oxygen under pressure.

The temperature rises "soup" begins to boil.

Type "gun" behind.

Included are drawing and the whole mechanism starts to rotate.

The process of separation. Very unusual, when you are near.

After the separation of copper waste into factions, some of which contain copper, that such a machine goes to the next melted.

Located next to very heavy and hot.

I put the "pot" in the oven.

On the reverse side of the furnace. This is copper, but it still contains a lot of impurities.

Molten metal falls on the carousel, where bottled in shape.

Wow!

When taking these shots I fired a tripod =)

While the carousel scrolls one turn, copper alloy has time to harden.

One of the shops.

Frozen workpiece manipulator puts in a water bath for cooling.

When the workpiece close to the water, the water begins to boil.

Pschschsch!

After all these processes are obtained here are blank. As you can see, many more impurities.

From blanks formed units and sent to the shop where the huge electrolytic bath.

Process cranes allow you to organize the cassette loading of the electrodes in an automatic mode. To handle the electrodes installed three automated lines: machine preparation of the anodes, the car and the car wash sdirki anode butt.

The electrolysis process is conducted with a constant circulation of the electrolyte in the electrolytic bath, in this regard, the workshop created a system of preparation of the electrolyte, preparation and dispensing of reagents, filtration solutions.

After unloading the bath cleaned from the bottom sludge, which is then extracted gold, silver, selenium, tellurium.

Unloading cassettes.

After the bath, the copper plate with a clean, sorted and placed into briquettes - Handling robots in fully automatic mode in order to send to the smelter again!

The finished raw materials.

In this workshop, have pure copper is converted to a liquid state for an extract from it wires.

The process is very beautiful.

Supportive gas burner.

The molten composition is obtained is such a blank, which is necessary to give a definite form.

Rolling.

Cut off all unnecessary.

The mixture is cooled to a temperature and

again heated, but pulling the wire required diameter.

Source: engineering-ru.livejournal.com