1392

The underworld

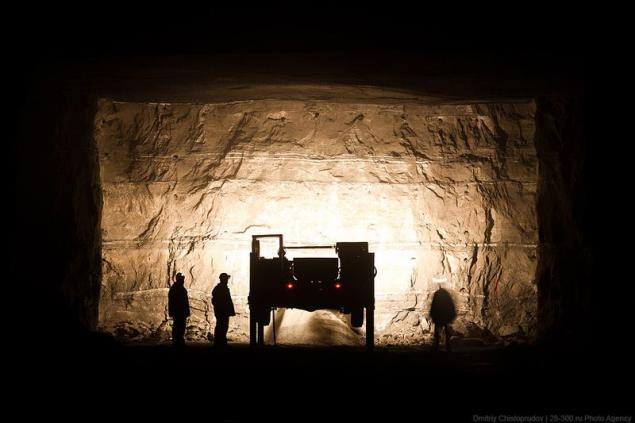

The extent of the mine and cameras capture the imagination. Opened in 1929, Novomoskovskoye gypsum deposit is considered the largest in Europe, and according to some estimates, and in the world. On the question of whether to match the volume of mining, with the volume of the Moscow metro, company employees smile: the magnitude of these underground facilities are simply incomparable.

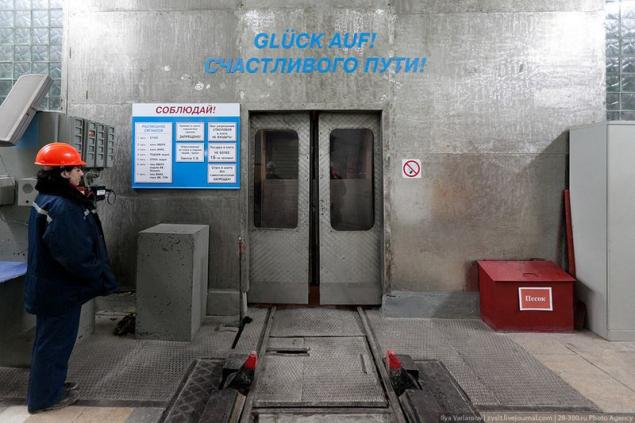

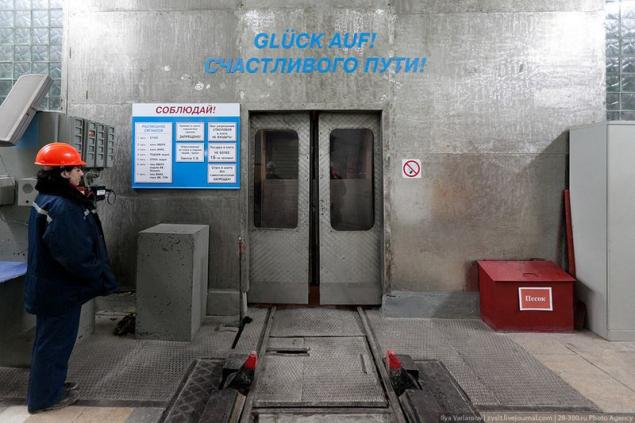

The journey begins with a nondescript entrance to the mine with the cage.

Before the descent we were given a protective suit, helmet and boots. As it turned out, not in vain)

Also, each individual received light and the so-called "self-rescuer" -kislorodnoe device you want to use in an emergency.

Descent to 130 meters below ground. Extracted breed - gypsum - a 11-timetrovy layer at this depth.

Just mine arranged five trunks. They serve for the descent into the pit of people and equipment, ventilation, and lift the extracted raw materials. Part of them are not in use.

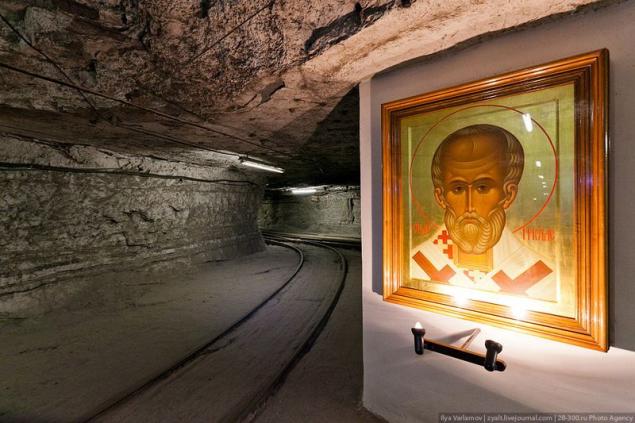

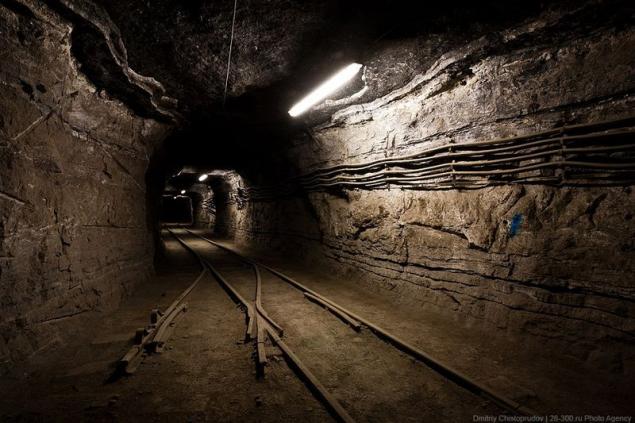

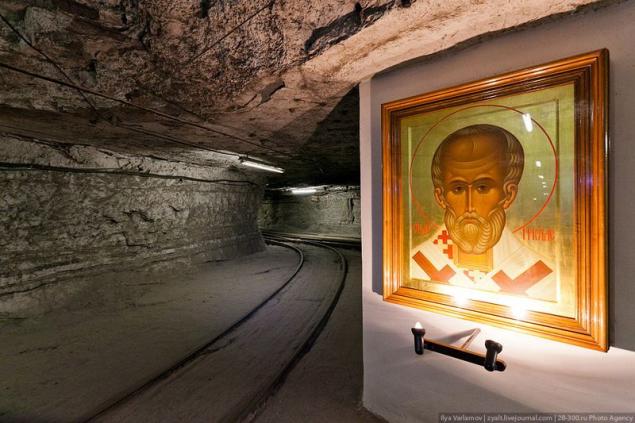

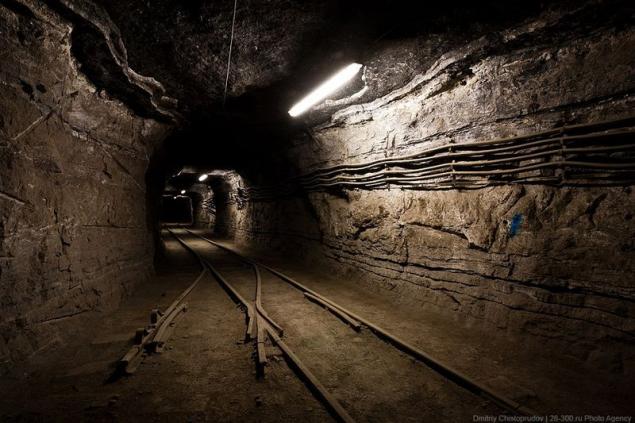

The first barrel was built in 1947. Transportation breed in those years was carried out only trolleys. The next stage of evolution - diesel vehicles. Now go to the mine dump, and extracted raw materials fed to the top special conveyor belt which are arranged in "buckets". On rails now only carry explosives to underground storage.

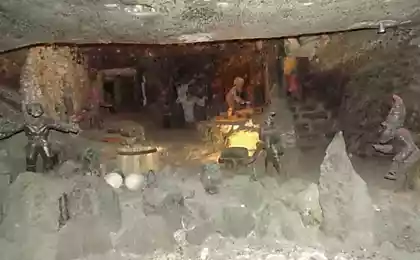

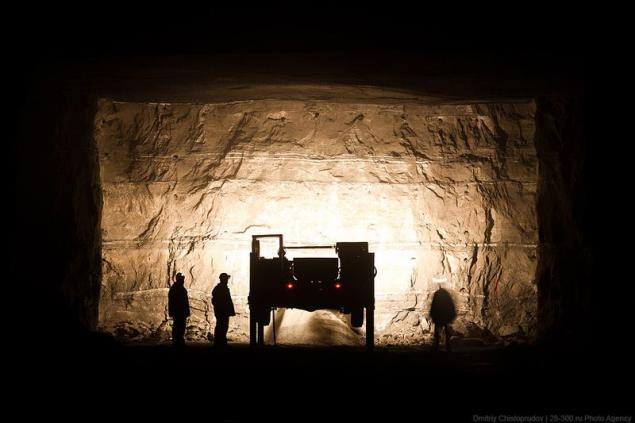

The total length of underground tunnels, more than 500 km! It's like from Moscow to the border with Ukraine. Without an underground park vehicles just can not do.

Each chamber exceeds the metro stations in two or three times. If you compare the amount of mining to the metro, then only with all subways CIS taken together.

The main roads have lighting.

Due to the strength of rock extracted, there is no need to lay mines in the tubing or somehow strengthen vaults tunnels.

The whole process looks like this:

- Drilling face special drilling equipment,

- Loading otburennyh blast holes with explosives,

- Blasting faces,

- Airing after blasting,

- Loading of gypsum in dump trucks and delivery to the complex crushing,

- Crushing,

- The rise of crushed stone surface,

- Loading products into railway wagons or service production through complex conveyor galleries.

Gypsum is quite strong and it can not produce the usual excavation equipment. To do this, at the bottom of the well is drilled and charged with explosives, which are produced directly at the facility.

The center of the chamber drilled six large wells that are not charged, and create a compensation surface facilitates the work of the explosion.

In 2000 he was completely eliminated manual labor drillers.

Oburivanie slaughter by a special drill setting Smaq BW 50.

Remote control setting.

Drilling of holes vertical.

After the explosion in the mine workings faces sits dust Blasters check availability quiescent charges and then starts loading of gypsum in the dump.

via Source

The journey begins with a nondescript entrance to the mine with the cage.

Before the descent we were given a protective suit, helmet and boots. As it turned out, not in vain)

Also, each individual received light and the so-called "self-rescuer" -kislorodnoe device you want to use in an emergency.

Descent to 130 meters below ground. Extracted breed - gypsum - a 11-timetrovy layer at this depth.

Just mine arranged five trunks. They serve for the descent into the pit of people and equipment, ventilation, and lift the extracted raw materials. Part of them are not in use.

The first barrel was built in 1947. Transportation breed in those years was carried out only trolleys. The next stage of evolution - diesel vehicles. Now go to the mine dump, and extracted raw materials fed to the top special conveyor belt which are arranged in "buckets". On rails now only carry explosives to underground storage.

The total length of underground tunnels, more than 500 km! It's like from Moscow to the border with Ukraine. Without an underground park vehicles just can not do.

Each chamber exceeds the metro stations in two or three times. If you compare the amount of mining to the metro, then only with all subways CIS taken together.

The main roads have lighting.

Due to the strength of rock extracted, there is no need to lay mines in the tubing or somehow strengthen vaults tunnels.

The whole process looks like this:

- Drilling face special drilling equipment,

- Loading otburennyh blast holes with explosives,

- Blasting faces,

- Airing after blasting,

- Loading of gypsum in dump trucks and delivery to the complex crushing,

- Crushing,

- The rise of crushed stone surface,

- Loading products into railway wagons or service production through complex conveyor galleries.

Gypsum is quite strong and it can not produce the usual excavation equipment. To do this, at the bottom of the well is drilled and charged with explosives, which are produced directly at the facility.

The center of the chamber drilled six large wells that are not charged, and create a compensation surface facilitates the work of the explosion.

In 2000 he was completely eliminated manual labor drillers.

Oburivanie slaughter by a special drill setting Smaq BW 50.

Remote control setting.

Drilling of holes vertical.

After the explosion in the mine workings faces sits dust Blasters check availability quiescent charges and then starts loading of gypsum in the dump.

via Source