545

Cable ship Alcatel-Lucent

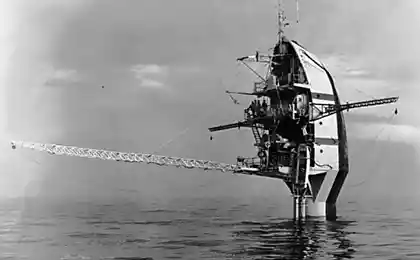

Photographer David Meyer ZDNet UK went with a tour of one of the three cable ships Alcatel-Lucent, designed for the installation of fiber-optic channels across the ocean floor.

That is the picture story about how to look under the water infrastructure of the Internet and with the help of the equipment pave backbone links.

The ship Ile de Batz is normally based in France, but he went to the port of Greenwich, to take some components from the local plant Alcatel-Lucent.

Each flight Ile de Batz lasts an average of 30 to 40 days. Under normal weather conditions, it can be laid up to 200 km of cable per day at a depth of up to 8 km. The service life of cables is estimated at 25 years.

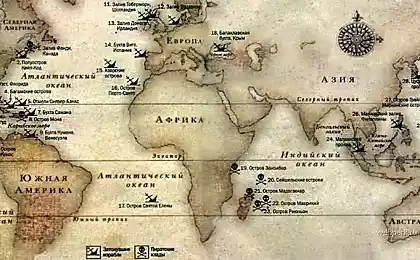

Currently, the market is quite stable laying underwater, it does not appear any new companies do not have much competition. The main project of the world, where now there is the most work - Africa. According to experts, in a few years can go large orders from Asia.

The cost of a large project can reach $ 500 million, so the telecoms usually finance the laying of submarine channels chipped.

On board the ship set stand with cables of varying thickness. Thicker laid closer to the surface (where they need good protection against anchors passing ships, trawls, the friction of the rocks in the tides and other damage) and thin - to the greatest depth, safe.

In the case of cable damage can be repaired, for that Alcatel-Lucent in the sea there are more ships, but each patch leads to the degradation of the channel, that is, its performance degrades.

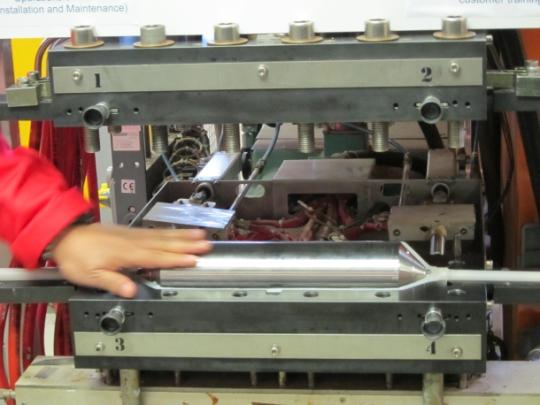

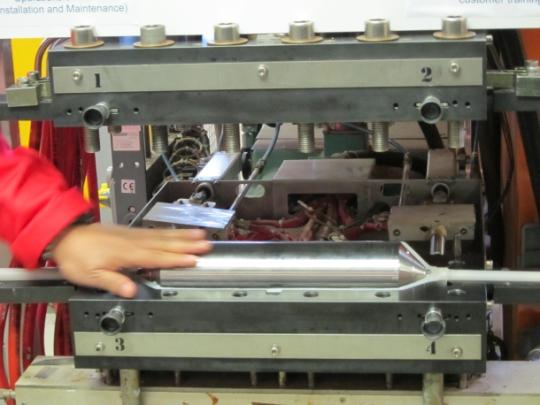

Here is a mechanism for attaching cables. The process requires high precision, do not look at a skein tape.

Next machine is needed for pressing the protective layer of the cable. In a sense, the ship is a small factory, because the cables often require additional treatment.

The ship has two large cable storage. Now they are empty, except for a small bunch of 17-mm fiber.

In general, in every store can hold up to 5,500 kilometers, or 3,000 tons of cable. There are a couple of spare storage for 250 tons.

The photo - series engines to supply cable from the repository to the stern, where it is lowered into the depths.

Next surrealist movement - not that other, as an underwater plow that buries the Fiber-to-three meters into the bottom. The plow works to a depth of 1, 5 km, it is considered that only in these waters go fishing boats and cables you need to hide from their anchors and trawls.

The laying of fiber helps to separate the control center, which is separated from the main navigation of the ship. It manages all the work, and sensors monitor weather conditions and topography.

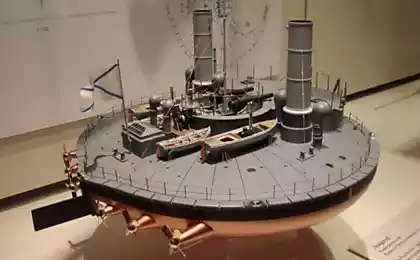

Alcatel-Lucent plant in Greenwich was built in the mid 19th century, there now doing amplifiers (repeaters), splitters and amplifiers for powering equipment.

Here is one of the amplifiers that put the entire length of the channel. This model two years ago provides a transfer rate of about 1, 5 terabit / s.

And it is - a typical splitter that lets you split the channel into two routes.

via

Source:

That is the picture story about how to look under the water infrastructure of the Internet and with the help of the equipment pave backbone links.

The ship Ile de Batz is normally based in France, but he went to the port of Greenwich, to take some components from the local plant Alcatel-Lucent.

Each flight Ile de Batz lasts an average of 30 to 40 days. Under normal weather conditions, it can be laid up to 200 km of cable per day at a depth of up to 8 km. The service life of cables is estimated at 25 years.

Currently, the market is quite stable laying underwater, it does not appear any new companies do not have much competition. The main project of the world, where now there is the most work - Africa. According to experts, in a few years can go large orders from Asia.

The cost of a large project can reach $ 500 million, so the telecoms usually finance the laying of submarine channels chipped.

On board the ship set stand with cables of varying thickness. Thicker laid closer to the surface (where they need good protection against anchors passing ships, trawls, the friction of the rocks in the tides and other damage) and thin - to the greatest depth, safe.

In the case of cable damage can be repaired, for that Alcatel-Lucent in the sea there are more ships, but each patch leads to the degradation of the channel, that is, its performance degrades.

Here is a mechanism for attaching cables. The process requires high precision, do not look at a skein tape.

Next machine is needed for pressing the protective layer of the cable. In a sense, the ship is a small factory, because the cables often require additional treatment.

The ship has two large cable storage. Now they are empty, except for a small bunch of 17-mm fiber.

In general, in every store can hold up to 5,500 kilometers, or 3,000 tons of cable. There are a couple of spare storage for 250 tons.

The photo - series engines to supply cable from the repository to the stern, where it is lowered into the depths.

Next surrealist movement - not that other, as an underwater plow that buries the Fiber-to-three meters into the bottom. The plow works to a depth of 1, 5 km, it is considered that only in these waters go fishing boats and cables you need to hide from their anchors and trawls.

The laying of fiber helps to separate the control center, which is separated from the main navigation of the ship. It manages all the work, and sensors monitor weather conditions and topography.

Alcatel-Lucent plant in Greenwich was built in the mid 19th century, there now doing amplifiers (repeaters), splitters and amplifiers for powering equipment.

Here is one of the amplifiers that put the entire length of the channel. This model two years ago provides a transfer rate of about 1, 5 terabit / s.

And it is - a typical splitter that lets you split the channel into two routes.

via

Source: