1058

Hatsan 125. Rehabilitation and recovery.

Once I got into the hands of the Turkish ekzemplyarchik airguns - Hatsan 125 CAMO. In the narrow circles pulevikov this rifle criticized as much and praise. The very long I wanted to take a new, but it was a pity the money first, and then the urgent need not see. And then went to the store to buy food fishes, saw in the window of a Russian MP-512, speaking of the Turkish rifles, it was found that once the seller bought Hassan, play and threw. He hinted that he might sell cheap. I asked to see this miracle and baaaaah himself 125th in camouflage. Break - vzlyad in the trunk: the trunk is smooth, rifling without scoring, along the entire length. A look inside - piston rust, is more dear weak spring, the seller gave a box, the box spring and the replacement reinforced cuff. By force platoon I understood that spring has kapets. For the money we had to take. Hands straight there, and for resuscitation and nothing else is not necessary. I took without bargaining.

I bring home a rifle. Well, I think it is necessary and shoot before dismantling. Break to pieces, I throw a bullet, take off the safety and tselyus in a puddle. Flakes and spray no. I break the trunk - a bullet in the barrel. Energy is not enough to push the bullet channel. Fires second time - a bullet spat stupid. So it is necessary to disassemble, take a picture and upload to PL.

In the pictures is the second demolition ruzhzha. Then I did thoroughly. For the first time stupidly changed the spring.

It will be 20 photos. Please do not break, the end will outline.

TTX rifle.

Gross Weight: 3.8 kg

Overall length: 1240 mm

Barrel length: 500 mm

Caliber, mm: 4, 5 mm

Butt Material: Plastic

Muzzle velocity, m / c: 380 m / s

Power source: Spring

Type of ammunition: Lead bullets

The size of the shop 1 bullet

Type of sight: rear sight and front sight

Type platoon: Fracture stem

That's rifle should look like. Photo from the Internet, ak my looks - on the last photo.

The hardest part of Hatsane - is to change the spring. Heavy duty springs is very tough. Someone makes home-made to adapt - I have the same machine.

To disassemble the rifle, first remove the bed - everything is simple. 4 screws on the left carved tsevyu and one under the trigger guard. Then the barrel in the spindle and tailstock of the compression-decompression of the spring.

Remove cross pin and removal grandmother. Here the spring is already hooked. New centimeters more than 5

So, all this wealth on the table.

What to do: remove stem and remake jamb curves hands. Change the cuff, after reading all internets right corners whispering and eliminates backlash trigger.

General view of the designer.

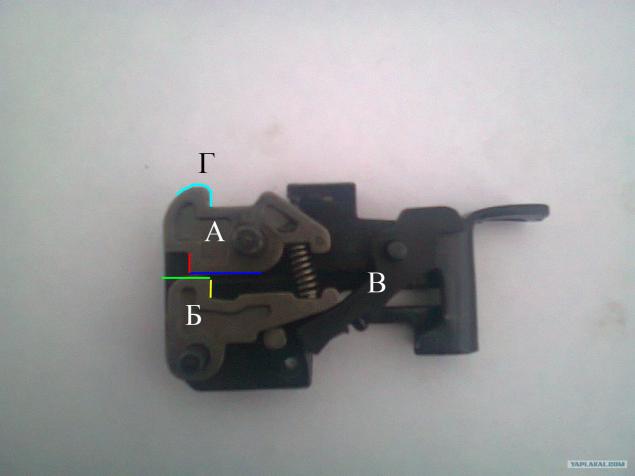

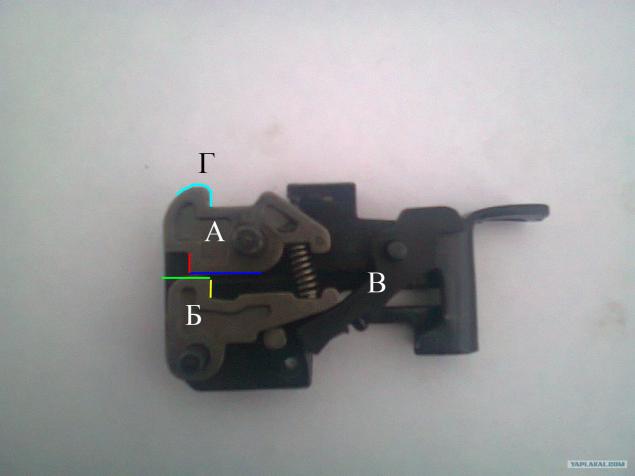

First of all - sear. That's how they are in the firing mechanism. This is not a cocked position.

So are sear in the cocked position. Tell us about schematics USM.

Sear A protrusion T clings to the piston in the platoon. To sear And not broken toe piston sear B green plane acts as a stop. Sear the push trigger sear and pushes B. When you select the distance between the red and yellow lines, sear A breaks down and releases the piston from the hook. That is the distance and affect the smooth descent.

There needs polishing. Metal whispered very durable. It yielded only diamond tools. Files are not taken. It is worth remembering that undermining whispered, decreases the value of the piston and the hook may occur spontaneous shot. In this case, I whispered to be replaced.

Parse and grind-polish. Make a direct and sharp corners, but remember about the toe piston

Approximately derive whispered. Corners sharp poverznosti polished. Fotkal on file.

The toe control on the assembled trigger. Each time it is necessary to assemble, disassemble. The hardest part - to put a spring-loaded between the sear. After the third time already put my eyes closed.

When whispered removed - proceed to the verification of the mechanism. First unassembled.

Then assembled in USM. The circle pointed out the window. Distance toe whispered disassembled and assembled different - this should be taken into account when finalizing

Go to the trunk.

The previous owner was finishing his rifle. Shot on conservation workers lubrication, which is unacceptable. The overflow seal was burnt through diesel came from poliurietana with Teflon carve new. Machined to a tolerance, the first closing of the barrel bushing obsadilo and subsequently became a perfect seal.

then in another school. The curves of the handle would make a chamfer at the entrance to drill. It turned out crooked. It is necessary to correct.

Correct'll American method.

The trunk close up, put a ball bearing, grease lapping valves and shurudit wooden leg. This theory

Now, on top of the wooden leg

But nifiga failed. Do not want to work this method. We will work in Russian.

the ball is welded to the rods. Bars in the drill and buzz minutes 15-20

After processing, the sharp edges align. Bullet Crossman supermagnum comes now fully, you should not use dobojnik. When closing the trunk skirt bullets is not injured.

Assembly time has come rifles.

Change the cuff. There is nothing complicated. Steamed in hot water and is mounted on the piston. Himself piston and spring grease with a thin layer of grease. I took vysokotepreraturnuyu for the mechanisms that work in the medium to + 200 * C

In no case do not lubricate the compressor itself. Otherwise, the shot lubrication of the pressure begins to burn and get shot of diesel. Loud, smells and breaks rifle.

Then collect the piston, put a spring in the machine and proceed with the trigger assembly.

Put the trigger housing. Then Sear A and B. Among them spring. And be sure to check the operation whispered.

Next is all in order. The sear is placed, the release hook, the spring fuse.

Luft trigger remove easily. The pin on the hook 3 mm. The opening is also 3 mm but play awesome, since the hook of plastic. Make vtulochku 4mm outer diameter, 3 mm internal. Reams hook and vtulit. Voila. Luft virtually has disappeared. On the supplied fuse virtually no backlash.

Filing whispered gave the result: a soft slope, if not completely pull the trigger and then release it - whispered themselves back in the cocked position (no earlier), which excludes spontaneous shot. In the spring charging tapped with a rubber hammer rifle - shot did not happen. Residual engages the piston and whispered And more than 2 mm. So everything is done correctly.

All collect

So now it looks rifle assembled.

Easy retrofit was successful. Shot in the pool 0, 76 grams. quiet. You can hear just a click of the piston and scream in the distance the sound of bullets at a target.

Power, too, came back to the rifle. To shoot bullets 0, 76 grams. from 20 meters hit the roof with roofing iron. With 50 meters hit the door from MDF.

To hunt a bit to the forty - 50 meters for free knocked magpie. The bullet went in the crash.

He took his rifle to make it and sell more expensive, but for some reason, wanted to leave. Turkish quality is Turkish, metal soft everywhere backlash + - kilometer, but the rifle is excellent.

That's all I wanted to say. Thank you for attention.

Source:

I bring home a rifle. Well, I think it is necessary and shoot before dismantling. Break to pieces, I throw a bullet, take off the safety and tselyus in a puddle. Flakes and spray no. I break the trunk - a bullet in the barrel. Energy is not enough to push the bullet channel. Fires second time - a bullet spat stupid. So it is necessary to disassemble, take a picture and upload to PL.

In the pictures is the second demolition ruzhzha. Then I did thoroughly. For the first time stupidly changed the spring.

It will be 20 photos. Please do not break, the end will outline.

TTX rifle.

Gross Weight: 3.8 kg

Overall length: 1240 mm

Barrel length: 500 mm

Caliber, mm: 4, 5 mm

Butt Material: Plastic

Muzzle velocity, m / c: 380 m / s

Power source: Spring

Type of ammunition: Lead bullets

The size of the shop 1 bullet

Type of sight: rear sight and front sight

Type platoon: Fracture stem

That's rifle should look like. Photo from the Internet, ak my looks - on the last photo.

The hardest part of Hatsane - is to change the spring. Heavy duty springs is very tough. Someone makes home-made to adapt - I have the same machine.

To disassemble the rifle, first remove the bed - everything is simple. 4 screws on the left carved tsevyu and one under the trigger guard. Then the barrel in the spindle and tailstock of the compression-decompression of the spring.

Remove cross pin and removal grandmother. Here the spring is already hooked. New centimeters more than 5

So, all this wealth on the table.

What to do: remove stem and remake jamb curves hands. Change the cuff, after reading all internets right corners whispering and eliminates backlash trigger.

General view of the designer.

First of all - sear. That's how they are in the firing mechanism. This is not a cocked position.

So are sear in the cocked position. Tell us about schematics USM.

Sear A protrusion T clings to the piston in the platoon. To sear And not broken toe piston sear B green plane acts as a stop. Sear the push trigger sear and pushes B. When you select the distance between the red and yellow lines, sear A breaks down and releases the piston from the hook. That is the distance and affect the smooth descent.

There needs polishing. Metal whispered very durable. It yielded only diamond tools. Files are not taken. It is worth remembering that undermining whispered, decreases the value of the piston and the hook may occur spontaneous shot. In this case, I whispered to be replaced.

Parse and grind-polish. Make a direct and sharp corners, but remember about the toe piston

Approximately derive whispered. Corners sharp poverznosti polished. Fotkal on file.

The toe control on the assembled trigger. Each time it is necessary to assemble, disassemble. The hardest part - to put a spring-loaded between the sear. After the third time already put my eyes closed.

When whispered removed - proceed to the verification of the mechanism. First unassembled.

Then assembled in USM. The circle pointed out the window. Distance toe whispered disassembled and assembled different - this should be taken into account when finalizing

Go to the trunk.

The previous owner was finishing his rifle. Shot on conservation workers lubrication, which is unacceptable. The overflow seal was burnt through diesel came from poliurietana with Teflon carve new. Machined to a tolerance, the first closing of the barrel bushing obsadilo and subsequently became a perfect seal.

then in another school. The curves of the handle would make a chamfer at the entrance to drill. It turned out crooked. It is necessary to correct.

Correct'll American method.

The trunk close up, put a ball bearing, grease lapping valves and shurudit wooden leg. This theory

Now, on top of the wooden leg

But nifiga failed. Do not want to work this method. We will work in Russian.

the ball is welded to the rods. Bars in the drill and buzz minutes 15-20

After processing, the sharp edges align. Bullet Crossman supermagnum comes now fully, you should not use dobojnik. When closing the trunk skirt bullets is not injured.

Assembly time has come rifles.

Change the cuff. There is nothing complicated. Steamed in hot water and is mounted on the piston. Himself piston and spring grease with a thin layer of grease. I took vysokotepreraturnuyu for the mechanisms that work in the medium to + 200 * C

In no case do not lubricate the compressor itself. Otherwise, the shot lubrication of the pressure begins to burn and get shot of diesel. Loud, smells and breaks rifle.

Then collect the piston, put a spring in the machine and proceed with the trigger assembly.

Put the trigger housing. Then Sear A and B. Among them spring. And be sure to check the operation whispered.

Next is all in order. The sear is placed, the release hook, the spring fuse.

Luft trigger remove easily. The pin on the hook 3 mm. The opening is also 3 mm but play awesome, since the hook of plastic. Make vtulochku 4mm outer diameter, 3 mm internal. Reams hook and vtulit. Voila. Luft virtually has disappeared. On the supplied fuse virtually no backlash.

Filing whispered gave the result: a soft slope, if not completely pull the trigger and then release it - whispered themselves back in the cocked position (no earlier), which excludes spontaneous shot. In the spring charging tapped with a rubber hammer rifle - shot did not happen. Residual engages the piston and whispered And more than 2 mm. So everything is done correctly.

All collect

So now it looks rifle assembled.

Easy retrofit was successful. Shot in the pool 0, 76 grams. quiet. You can hear just a click of the piston and scream in the distance the sound of bullets at a target.

Power, too, came back to the rifle. To shoot bullets 0, 76 grams. from 20 meters hit the roof with roofing iron. With 50 meters hit the door from MDF.

To hunt a bit to the forty - 50 meters for free knocked magpie. The bullet went in the crash.

He took his rifle to make it and sell more expensive, but for some reason, wanted to leave. Turkish quality is Turkish, metal soft everywhere backlash + - kilometer, but the rifle is excellent.

That's all I wanted to say. Thank you for attention.

Source: