672

Plant «Chery» China

writes russos

It will be about 40 pictures.

End outline the

In April, I visited in China is not only the Beijing Motor Show, but Plant «Chery», located in Wuhu, Anhui Province.

«Chery» (in Chinese is a kind of "special blessing") was founded in 1997 on the initiative of the Municipality of Wuhu (Wuhu) in Anhui Province. Its shareholders became more public companies and holdings of Anhui Province, as well as small investors. The equipment was purchased for European Ford plant for $ 25 million. The production of cars began in 1999 after the acquisition of a license for the chassis of Toledo Seat.

A detailed history of the motor companies you can find on Wikipedia (where I got the top quote), and I'll show you the plant itself.

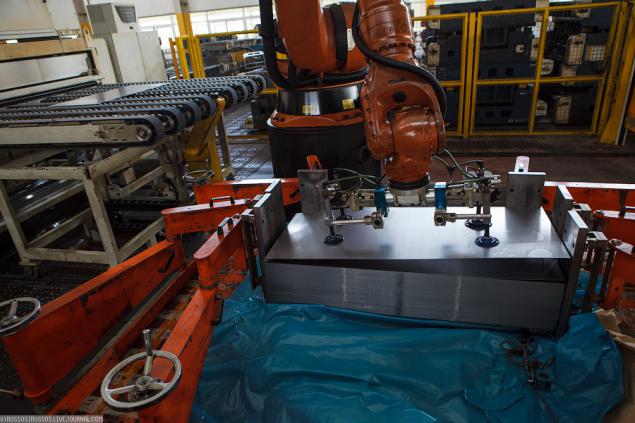

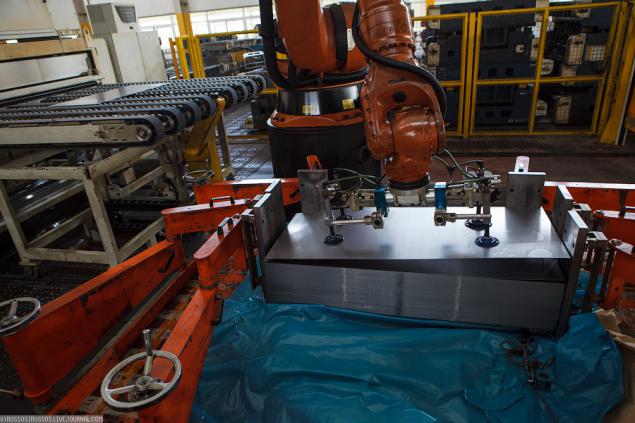

1. Production of the car starts with stamping parts of the body.

2. The workshops are equipped with a fully robotic lines.

3. The workers carried out a quality control.

4. Storage Storage of stamped parts.

5. The assembly shop.

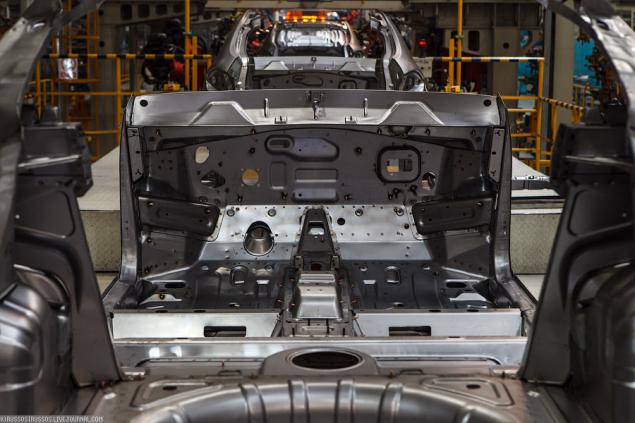

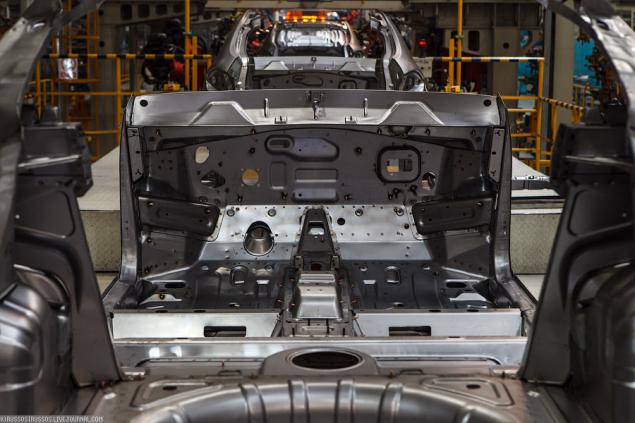

6. Incomprehensible model body. Someone tell me what it is?

7. Mandatory stand with product samples.

8. Assembling the machine begins on the stocks where small body parts are welded into larger ones.

9. At this point, using the labor of workers - they put the items in a pile and sealed them with a special device.

10. The assembly line of body parts.

11. Next is the major part comes into possession of robots.

12. Conveyor "charged" container components that robot takes out and puts in place. And his colleague welded a new part.

13. "Convertible»

14. Some large items (for example, the whole body side) set in place under the control of the workers.

15. Then again, robots weld the body together.

16. The shop installed a central management system that is optimized for the equipment developed in China.

17. The existing production capacity is sufficient for the production of 800 thousand cars. With the introduction into operation of two production sites in Wuhu production volume will increase up to a million.

18. Next, the body falls on the painting (it was impossible to remove), and then - to the final assembly line, where it is already turning into a car.

(sorry distracted)

19. Install the windshield.

20. The population of the urban district of Wuhu is about 3 million people. «Chery» - one of the two largest enterprises in the city. Total factory employs about thirty thousand people, most of them - young people 25-30 years.

21. In the domestic market are mainly machines with a spacious living, but gradually the European tradition of dark salons penetrates into China.

22. At the same time the plant is going to several models.

23. Workers are programs subsidized food, health care, transportation and housing. Generally, to get a job at a large enterprise in China is considered a great success. The workers hold on to their seats.

24. Production line of engines.

25. "Marriage" - the connection of the body and chassis.

26. In 2011, the «Chery» has sold more than 160 thousand cars outside China. This figure was a record not only for the company itself, but also for the Chinese automotive industry.

27. The panels on the bodywork protect the paintwork from scratches during assembly of the machine.

28. Of course, you can not

29. Almost ready Chery Tiggo.

30. One Chinese features - these jars with water or tea. Almost all the Chinese people go to them. At the airport, they poured water from them, SAB and verifies that it is empty. Next to the Chinese is a special column and refill it with water.

31. Thousands of them ...

32. Some local stand.

33. Mini-truck.

34. Research Center Chery Automobile Test & Technology Center, which opened in 2010 and cost the company more than half a billion yuan - the largest in Asia. He is among the five most-equipped laboratories in the world. There are testing new engines, equipment, systems and so on. Total can be carried out more than 1,800 tests.

35. The special test area where the work is carried out verification of all the mechanisms of the vehicle under certain climatic conditions. The temperature range which can be specified in the cabin - from -20 to +40. During the test, the fuel used, typical for the region - thus fully simulated environment in which the vehicle is operated.

36. Spayz photo was surprised that such cars ride not only on the territory of the plant, but also in the city.

37. Crash center of Chery - the largest in Asia. Tests are carried out on the system safety assessment NCAP. Since opening in 2010, the center has been more than 300 test vehicles for durability. Alas, in the middle of shooting forbidden, because there was carried out the test of the new car, which is still terrible secret.

38. Proving Ground.

All

Source:

It will be about 40 pictures.

End outline the

In April, I visited in China is not only the Beijing Motor Show, but Plant «Chery», located in Wuhu, Anhui Province.

«Chery» (in Chinese is a kind of "special blessing") was founded in 1997 on the initiative of the Municipality of Wuhu (Wuhu) in Anhui Province. Its shareholders became more public companies and holdings of Anhui Province, as well as small investors. The equipment was purchased for European Ford plant for $ 25 million. The production of cars began in 1999 after the acquisition of a license for the chassis of Toledo Seat.

A detailed history of the motor companies you can find on Wikipedia (where I got the top quote), and I'll show you the plant itself.

1. Production of the car starts with stamping parts of the body.

2. The workshops are equipped with a fully robotic lines.

3. The workers carried out a quality control.

4. Storage Storage of stamped parts.

5. The assembly shop.

6. Incomprehensible model body. Someone tell me what it is?

7. Mandatory stand with product samples.

8. Assembling the machine begins on the stocks where small body parts are welded into larger ones.

9. At this point, using the labor of workers - they put the items in a pile and sealed them with a special device.

10. The assembly line of body parts.

11. Next is the major part comes into possession of robots.

12. Conveyor "charged" container components that robot takes out and puts in place. And his colleague welded a new part.

13. "Convertible»

14. Some large items (for example, the whole body side) set in place under the control of the workers.

15. Then again, robots weld the body together.

16. The shop installed a central management system that is optimized for the equipment developed in China.

17. The existing production capacity is sufficient for the production of 800 thousand cars. With the introduction into operation of two production sites in Wuhu production volume will increase up to a million.

18. Next, the body falls on the painting (it was impossible to remove), and then - to the final assembly line, where it is already turning into a car.

(sorry distracted)

19. Install the windshield.

20. The population of the urban district of Wuhu is about 3 million people. «Chery» - one of the two largest enterprises in the city. Total factory employs about thirty thousand people, most of them - young people 25-30 years.

21. In the domestic market are mainly machines with a spacious living, but gradually the European tradition of dark salons penetrates into China.

22. At the same time the plant is going to several models.

23. Workers are programs subsidized food, health care, transportation and housing. Generally, to get a job at a large enterprise in China is considered a great success. The workers hold on to their seats.

24. Production line of engines.

25. "Marriage" - the connection of the body and chassis.

26. In 2011, the «Chery» has sold more than 160 thousand cars outside China. This figure was a record not only for the company itself, but also for the Chinese automotive industry.

27. The panels on the bodywork protect the paintwork from scratches during assembly of the machine.

28. Of course, you can not

29. Almost ready Chery Tiggo.

30. One Chinese features - these jars with water or tea. Almost all the Chinese people go to them. At the airport, they poured water from them, SAB and verifies that it is empty. Next to the Chinese is a special column and refill it with water.

31. Thousands of them ...

32. Some local stand.

33. Mini-truck.

34. Research Center Chery Automobile Test & Technology Center, which opened in 2010 and cost the company more than half a billion yuan - the largest in Asia. He is among the five most-equipped laboratories in the world. There are testing new engines, equipment, systems and so on. Total can be carried out more than 1,800 tests.

35. The special test area where the work is carried out verification of all the mechanisms of the vehicle under certain climatic conditions. The temperature range which can be specified in the cabin - from -20 to +40. During the test, the fuel used, typical for the region - thus fully simulated environment in which the vehicle is operated.

36. Spayz photo was surprised that such cars ride not only on the territory of the plant, but also in the city.

37. Crash center of Chery - the largest in Asia. Tests are carried out on the system safety assessment NCAP. Since opening in 2010, the center has been more than 300 test vehicles for durability. Alas, in the middle of shooting forbidden, because there was carried out the test of the new car, which is still terrible secret.

38. Proving Ground.

All

Source: