911

Electroplating Home

Will ph 9, and letters

Today we talk about turning the most ordinary objects: leaves, shells and other debris in almost beautiful jewelry and decorative ornaments. It's about galvanizing? and how it can be practiced at home

To start a drop of history and theory.

In 1838, Russian physicist BS Jacobi in experiments noted that if the electricity flowing through the electrolyte, the cathode is deposited on the metal layer. In further experiments it was found out that the metal is deposited uniformly over the entire surface of the cathode creating a copy. Thus began the electroforming and the overall direction of the applied electrochemistry.

What happens in this case?

As mentioned above, deposited at the cathode, metal ions contained in the electrolyte. In these electrolyte ions are replenished from the anode - a plate of the same metal.

Enough theory, turn to practice.

Last week I visited the idea to try to practice this same electroforming, good at first glance, nothing difficult in it is not present. The simplest and most common form of galvanization - plating of copper, good and electrolyte for a simple plate of copper and not a problem to get it.

It Said - done: acquired the power supply, the electrolyte, and began the process.

So, take a subject that we are going to "copperplate". Since the end of winter in the yard and beautiful leaves, flowers, and other gifts of nature you will not find, I decided to take the shell, the blessing after years of trips to the sea I have accumulated a fair amount.

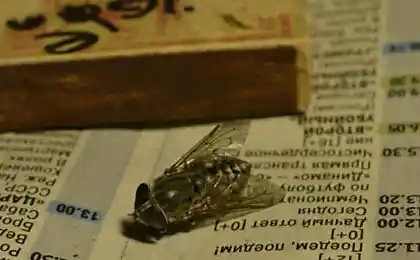

A prerequisite of a Conductive cathode. Shell, of course, does not hold a current, so it is necessary to create a cover. I used graphite spray, but the fit and pounded lead from a simple pencil, it looks like that coated graphite shell:

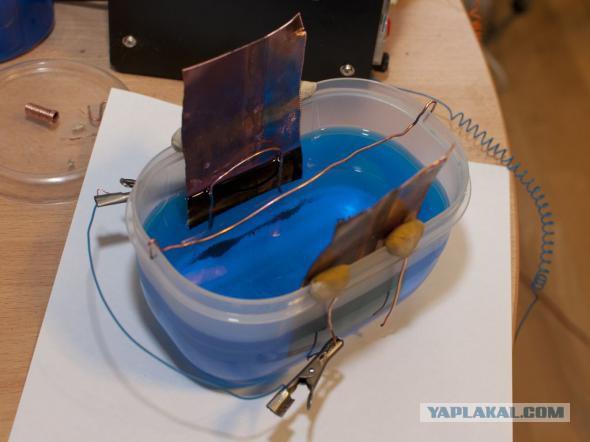

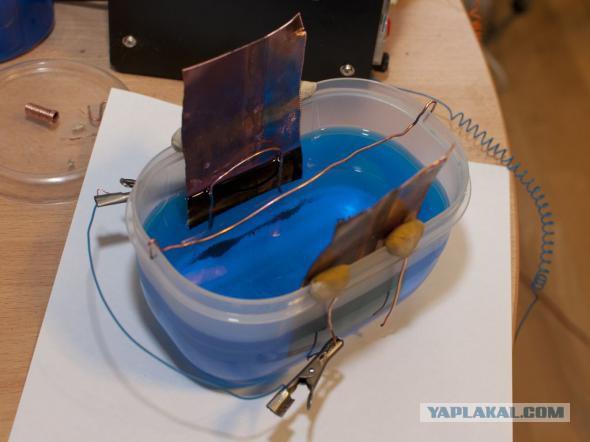

While a layer of graphite shell cos I assembled improvised plating bath. With it, everything just fit any container, resistant to chemical reagents. In my case, the usual plastic container for 50 rubles. then we need to mount under the anode and cathode, in general it looked like that my bath: copper plates on the sides - anodes, center mount for cathode - shells, electrolyte is based on copper sulfate.

And we still need a constant current source with adjustable amperage. Very powerful source we do not nat, needed for galvanizing current 0.02 amperes per square centimeter and 1 voltage 2-3 volts. In general, it can be collected from your regular mobile charger unit, but I decided not to fence absolutely amateurish and took a cheap Chinese source:

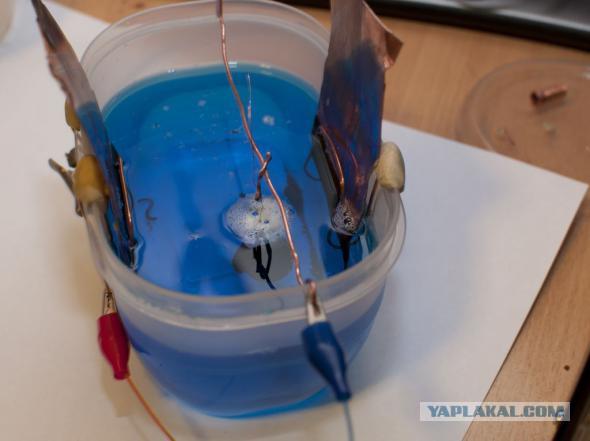

Well, Well, we're done: tray is made, the subject is covered with graphite, and placed in a tray, because the subject we have covered on both sides, in the bath has two anode on both sides, plus connected to the anodes, negative - to the cathode ... Let's go!

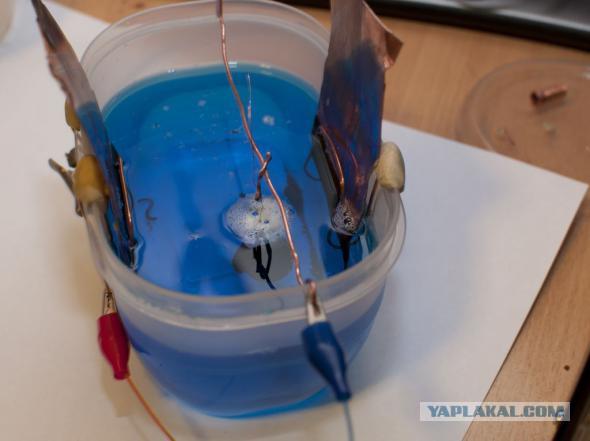

Notice the bubbles on the cathode, they mean that the process has begun, and hydrogen is released from the electrolyte. It is, of course, a trace amount, but for security reasons, though it is advisable not to smoke near and generally ensure fire safety. The question of overall security I will reveal later.

So, the process is, the process is not very fast, and see what it turns out I want to, so I could not resist, and after 10 minutes, pulled the shell and looked what was happening to her.

We see that the process is going, but our shell covered with copper is not yet fully, so continues to go down in the tub shell and continue.

And while there is a galvanizing, tell a little about the intricacies and pitfalls.

The first difficulty I encountered was that's what: Copper object must be completely immersed in the electrolyte, while not touch the bottom and hang on the wire. well if we Copper thing with any handle, such as a leaf or better yet with a ready ear for the suspension (bead any), and what to do if you have nothing to cling to, as in my case? I went through the spike: fixed a thin copper wire to the shell with a piece of sculptural clay, but it is bad, because the clay reacts with the electrolyte, and how it will affect the properties of the electrolyte and in general - kustarschina. I think on how to be.

Second, for some reason, on the conductor, and places the cathode formed dendrite: pink porous substance that crumbles and does not shine. Why is formed is not clear, too, will be monitored.

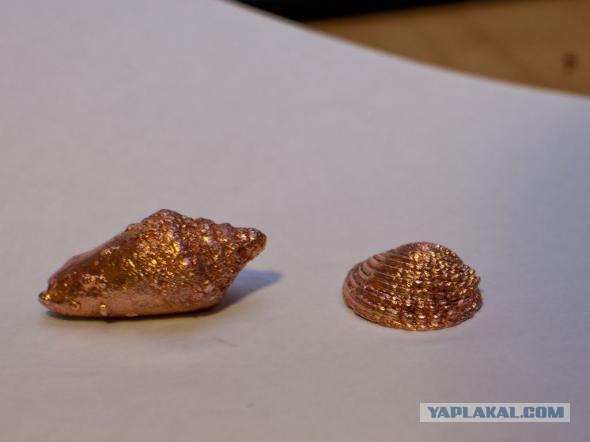

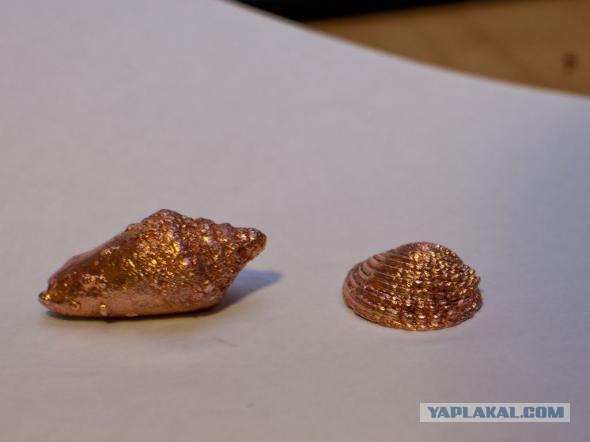

It took another 20 minutes we take out our subject, thoroughly wash it in water destilirovannoy and look what happened

As you can see we have a smooth coat, seated firmly enough (nail knock over him I could not), a brilliant and beautiful.

A few words about the rules of safety. The good thing there are very few and they are of general importance.

First, though, we electrolyte and not very harmful, yet it contains copper sulfate and sulfuric acid, '30 per liter, yet so work better with gloves, afraid of getting in your eyes and mouth.

Secondly, since we are dealing with an open electrical conductor, the general safety measures also should observe though tension there and not dangerous, but better safe, as they say ...

Third, as I mentioned, in the process of galvanizing hydrogen is released, and open flames near should not be

As a first experience, I used copper, but the fundamental difference between copper and other metals present, so if you pull out a desired metal and the electrolyte, you can, for example, silver or brass desired item. Just remember that not all electrolytes as harmless as copper. For example silvering used electrolyte based on cyanide, and you need a good hood.

And most importantly, without significant costs can make beautiful things right at home. Dare and you will be prepared so that's the beauty.

Source:

Today we talk about turning the most ordinary objects: leaves, shells and other debris in almost beautiful jewelry and decorative ornaments. It's about galvanizing? and how it can be practiced at home

To start a drop of history and theory.

In 1838, Russian physicist BS Jacobi in experiments noted that if the electricity flowing through the electrolyte, the cathode is deposited on the metal layer. In further experiments it was found out that the metal is deposited uniformly over the entire surface of the cathode creating a copy. Thus began the electroforming and the overall direction of the applied electrochemistry.

What happens in this case?

As mentioned above, deposited at the cathode, metal ions contained in the electrolyte. In these electrolyte ions are replenished from the anode - a plate of the same metal.

Enough theory, turn to practice.

Last week I visited the idea to try to practice this same electroforming, good at first glance, nothing difficult in it is not present. The simplest and most common form of galvanization - plating of copper, good and electrolyte for a simple plate of copper and not a problem to get it.

It Said - done: acquired the power supply, the electrolyte, and began the process.

So, take a subject that we are going to "copperplate". Since the end of winter in the yard and beautiful leaves, flowers, and other gifts of nature you will not find, I decided to take the shell, the blessing after years of trips to the sea I have accumulated a fair amount.

A prerequisite of a Conductive cathode. Shell, of course, does not hold a current, so it is necessary to create a cover. I used graphite spray, but the fit and pounded lead from a simple pencil, it looks like that coated graphite shell:

While a layer of graphite shell cos I assembled improvised plating bath. With it, everything just fit any container, resistant to chemical reagents. In my case, the usual plastic container for 50 rubles. then we need to mount under the anode and cathode, in general it looked like that my bath: copper plates on the sides - anodes, center mount for cathode - shells, electrolyte is based on copper sulfate.

And we still need a constant current source with adjustable amperage. Very powerful source we do not nat, needed for galvanizing current 0.02 amperes per square centimeter and 1 voltage 2-3 volts. In general, it can be collected from your regular mobile charger unit, but I decided not to fence absolutely amateurish and took a cheap Chinese source:

Well, Well, we're done: tray is made, the subject is covered with graphite, and placed in a tray, because the subject we have covered on both sides, in the bath has two anode on both sides, plus connected to the anodes, negative - to the cathode ... Let's go!

Notice the bubbles on the cathode, they mean that the process has begun, and hydrogen is released from the electrolyte. It is, of course, a trace amount, but for security reasons, though it is advisable not to smoke near and generally ensure fire safety. The question of overall security I will reveal later.

So, the process is, the process is not very fast, and see what it turns out I want to, so I could not resist, and after 10 minutes, pulled the shell and looked what was happening to her.

We see that the process is going, but our shell covered with copper is not yet fully, so continues to go down in the tub shell and continue.

And while there is a galvanizing, tell a little about the intricacies and pitfalls.

The first difficulty I encountered was that's what: Copper object must be completely immersed in the electrolyte, while not touch the bottom and hang on the wire. well if we Copper thing with any handle, such as a leaf or better yet with a ready ear for the suspension (bead any), and what to do if you have nothing to cling to, as in my case? I went through the spike: fixed a thin copper wire to the shell with a piece of sculptural clay, but it is bad, because the clay reacts with the electrolyte, and how it will affect the properties of the electrolyte and in general - kustarschina. I think on how to be.

Second, for some reason, on the conductor, and places the cathode formed dendrite: pink porous substance that crumbles and does not shine. Why is formed is not clear, too, will be monitored.

It took another 20 minutes we take out our subject, thoroughly wash it in water destilirovannoy and look what happened

As you can see we have a smooth coat, seated firmly enough (nail knock over him I could not), a brilliant and beautiful.

A few words about the rules of safety. The good thing there are very few and they are of general importance.

First, though, we electrolyte and not very harmful, yet it contains copper sulfate and sulfuric acid, '30 per liter, yet so work better with gloves, afraid of getting in your eyes and mouth.

Secondly, since we are dealing with an open electrical conductor, the general safety measures also should observe though tension there and not dangerous, but better safe, as they say ...

Third, as I mentioned, in the process of galvanizing hydrogen is released, and open flames near should not be

As a first experience, I used copper, but the fundamental difference between copper and other metals present, so if you pull out a desired metal and the electrolyte, you can, for example, silver or brass desired item. Just remember that not all electrolytes as harmless as copper. For example silvering used electrolyte based on cyanide, and you need a good hood.

And most importantly, without significant costs can make beautiful things right at home. Dare and you will be prepared so that's the beauty.

Source: