673

Rifles ORSIS: "How is it done"

Moscow arms factory SC "Promtehnologiya" / Brand ORSIS

Construction of the plant began in 2010, after the master of sports of shooting and future enterprise director Alexei Sorokin shared the idea of creating the production of high-precision rifle with a co-owner of the "N-Trance" Konstantin Nikolayev. Then the project got a second investor holding Ru-com Michael Abyzova. Production of rifles under the brand Orsis (consonant with the Latin name Ursus - «Bear") began in March 2011. Now the plant produces five types of hunting and sporting rifles, and also produces under license from the Austrian Glock pistols and rifles Italian Marocchi. The most popular model is a tactical ORSIS T-5000 - with her winning the Russian secret service in international shooting competitions. The company produces around 1,200 products a year, 60% of them in hunting weapons, the rest - sporting rifles.

41 photos via aniskin1968

Photo: Ivan Gushchin

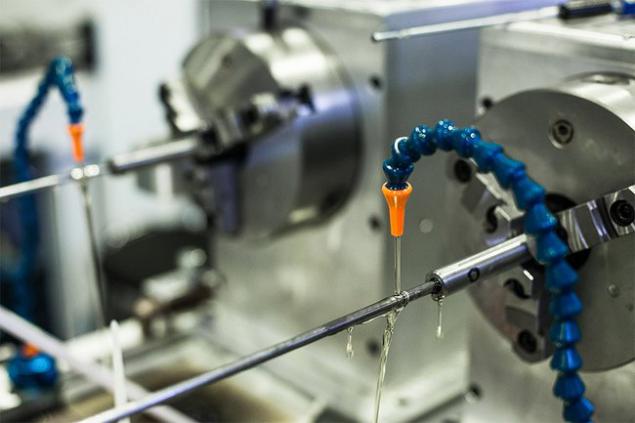

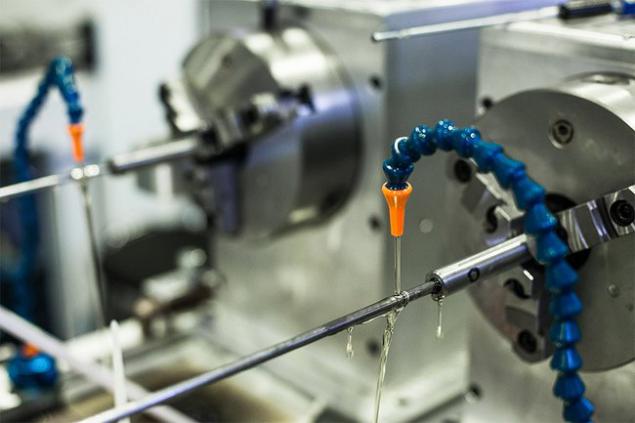

The rifle consists of three main parts: the barrel, bolt group and lodges with the butt. The manufacturing process begins with the barrel weapons. Preparations for them are coming to the company from the United States. They are made of a special stainless steel weapons. The machine is first drilled in the workpiece hole, the width of which depends on the caliber rifle future. Then the barrel shaped. Then make cuts inside - 4-6 spiral bands, helping to stabilize the trajectory of the bullet. They are cut special metal hook shape, which is also manufactured in the factory. The tool is included in the fixed workpiece and the cutter leaves a trail of deep one micron. To facilitate cutting the barrel pours oil. Stem cutting process takes 3-5 hours. For one marked slot tool should go inside 60-80 times. Thereafter barrel manually polished tin-lead lap.

Laboratory specialists probed bore borescope for defects - scratches, cracks or sinks. The trunk is checked several times after drilling holes, cutting and polishing.

Larger parts of the slide are made in eight milling plants. Each of them performs a single operation.

For each model, make their bed. It provides the structure rigidity. For tactical rifles used boxes made of aluminum, for sports - from a special weapon laminate. In addition, the plant makes to order box of precious wood, such as walnut. A billet of this part can cost tens of thousands of rubles. First, the future bed process on the milling machine, then hand polished master it, the laser is applied to branded notches and repeatedly impregnated with oil. During one shift foreman produces 2-3 lodge.

After the parts are tested, they are sorted into boxes and sent to the assembly site. Each box is attached paper, which shows the data of the customer, the type of weapon and caliber. Specialist brings together details of the bolt group, attaches them to the trunk. Then begins the process of Glass beddinga. In the box to rifle a special paste is applied, it is placed in the metal components and leave for a day to dry. Then again, take out the details and give the painting, and remains on a bed of fine print that allows you to adjust the wood under the metal. This ensures greater precision weapons.

After painting parts are joined together again. Specialists of the technical control department inspect the finished product, and draw the conclusion that the rifle is ready to fire. Every day, the plant produces 5-6 rifles.

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

A small hole in the target - the trace of the 16 bullets hit.

Source:

Construction of the plant began in 2010, after the master of sports of shooting and future enterprise director Alexei Sorokin shared the idea of creating the production of high-precision rifle with a co-owner of the "N-Trance" Konstantin Nikolayev. Then the project got a second investor holding Ru-com Michael Abyzova. Production of rifles under the brand Orsis (consonant with the Latin name Ursus - «Bear") began in March 2011. Now the plant produces five types of hunting and sporting rifles, and also produces under license from the Austrian Glock pistols and rifles Italian Marocchi. The most popular model is a tactical ORSIS T-5000 - with her winning the Russian secret service in international shooting competitions. The company produces around 1,200 products a year, 60% of them in hunting weapons, the rest - sporting rifles.

41 photos via aniskin1968

Photo: Ivan Gushchin

The rifle consists of three main parts: the barrel, bolt group and lodges with the butt. The manufacturing process begins with the barrel weapons. Preparations for them are coming to the company from the United States. They are made of a special stainless steel weapons. The machine is first drilled in the workpiece hole, the width of which depends on the caliber rifle future. Then the barrel shaped. Then make cuts inside - 4-6 spiral bands, helping to stabilize the trajectory of the bullet. They are cut special metal hook shape, which is also manufactured in the factory. The tool is included in the fixed workpiece and the cutter leaves a trail of deep one micron. To facilitate cutting the barrel pours oil. Stem cutting process takes 3-5 hours. For one marked slot tool should go inside 60-80 times. Thereafter barrel manually polished tin-lead lap.

Laboratory specialists probed bore borescope for defects - scratches, cracks or sinks. The trunk is checked several times after drilling holes, cutting and polishing.

Larger parts of the slide are made in eight milling plants. Each of them performs a single operation.

For each model, make their bed. It provides the structure rigidity. For tactical rifles used boxes made of aluminum, for sports - from a special weapon laminate. In addition, the plant makes to order box of precious wood, such as walnut. A billet of this part can cost tens of thousands of rubles. First, the future bed process on the milling machine, then hand polished master it, the laser is applied to branded notches and repeatedly impregnated with oil. During one shift foreman produces 2-3 lodge.

After the parts are tested, they are sorted into boxes and sent to the assembly site. Each box is attached paper, which shows the data of the customer, the type of weapon and caliber. Specialist brings together details of the bolt group, attaches them to the trunk. Then begins the process of Glass beddinga. In the box to rifle a special paste is applied, it is placed in the metal components and leave for a day to dry. Then again, take out the details and give the painting, and remains on a bed of fine print that allows you to adjust the wood under the metal. This ensures greater precision weapons.

After painting parts are joined together again. Specialists of the technical control department inspect the finished product, and draw the conclusion that the rifle is ready to fire. Every day, the plant produces 5-6 rifles.

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

A small hole in the target - the trace of the 16 bullets hit.

Source: