835

The revolution of the 21st century! Invented paper ... again

In the near future, the paper will be stronger than cast iron. Swedish researchers were able to get superbumagu - very solid, almost no ability to deform and break. And, amazingly, a new paper made from completely organic substances, to be exact, from the same pulp as usual.

Today, paper is made from wood, which is half of the pulp. In plant cell walls of the cellulose molecule are connected to the fiber diameter of not more than 20 nanometers (1 nanometer - 10-9 m) - which is five thousand times thinner than a human hair. These fibers and the reinforcing cell walls.

Nowadays pulp are widely used in the production of cellophane and other inexpensive materials, completely ignoring its mechanical properties. When extracted from wood pulp for paper, wood and crushed. As a result of damaged and cellulose fibers - they are much less durable. Hence the ease with which we can break the paper.

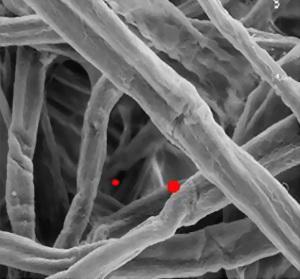

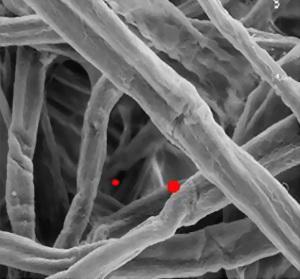

The new method is the production of paper, invented by clever Swedes, is as follows. Wood pulp is destroyed by enzymes and crushed mechanically. Due to the shear forces cellulose neatly separated into their famous fiber. They are in the water in a suspended state, and when the water drained, the fibers themselves are connected by hydrogen bonds - the so-obtained thin sheets nanopaper.

Mechanical tests show that the tensile strength of the finest paper - 214 megapascals - this means that it is stronger than cast iron and almost as strong as structural steel. For comparison, the tensile strength of plain paper - 1 megapascals.

Besides the fortress nanopaper also has the property of flexibility - it is stretched and resists severe stress - ie, deforms much less than ordinary paper sheets.

With this paper will not make the problem bungled vest at home - turned roll and you are in the tank.

Today, paper is made from wood, which is half of the pulp. In plant cell walls of the cellulose molecule are connected to the fiber diameter of not more than 20 nanometers (1 nanometer - 10-9 m) - which is five thousand times thinner than a human hair. These fibers and the reinforcing cell walls.

Nowadays pulp are widely used in the production of cellophane and other inexpensive materials, completely ignoring its mechanical properties. When extracted from wood pulp for paper, wood and crushed. As a result of damaged and cellulose fibers - they are much less durable. Hence the ease with which we can break the paper.

The new method is the production of paper, invented by clever Swedes, is as follows. Wood pulp is destroyed by enzymes and crushed mechanically. Due to the shear forces cellulose neatly separated into their famous fiber. They are in the water in a suspended state, and when the water drained, the fibers themselves are connected by hydrogen bonds - the so-obtained thin sheets nanopaper.

Mechanical tests show that the tensile strength of the finest paper - 214 megapascals - this means that it is stronger than cast iron and almost as strong as structural steel. For comparison, the tensile strength of plain paper - 1 megapascals.

Besides the fortress nanopaper also has the property of flexibility - it is stretched and resists severe stress - ie, deforms much less than ordinary paper sheets.

With this paper will not make the problem bungled vest at home - turned roll and you are in the tank.

Psychedelic methods of dealing with the worst offenders SDA

Cars Jaguar D-Type and E2A at Bonhams auction