196

An experienced plumber saw me winding up a fume tape, shouted and did everything himself.

Nowadays, you have to save on everything, including plumbing services, especially if the breakdown is small and does not threaten to flood the house. For example, you can tighten the leaking tap yourself, the benefit on YouTube is enough video lessons, and consumables can be bought almost at every corner. Self-repair also pushes the abundance of modern convenient means for sealing. Now you don’t have to mess with pasta and bagels, getting your hands dirty and everything around. It is enough to do with a couple of coils of fume tape (FUM is an abbreviation for "fluoroplastic sealing material"). However, fume tape (or simply fume) also need to be able to use. In this article you will learn how to wind fum tape, in which cases to use it and what are pitfalls.

How to wrap fume tape How to wind fume tape? First of all, remember that the tape must be wound in the direction of the thread. Otherwise, when twisting the connection, it simply peels off and will not be able to ensure tightness. Simply put, in 99% of cases, you need to roll the tape clockwise.

Slightly stretch the tape and wind it so that it tightly covers the thread.

Also thin tape can be stretched to the state of thread. Sweat this thread of the groove of the thread, then slightly loosen the tension and already the entire width of the tape fix the resulting seal.

By the way, even the position of the coil matters. Although the tape is absolutely the same from above and below, it is much more convenient to wind it with the outer (upper) side.

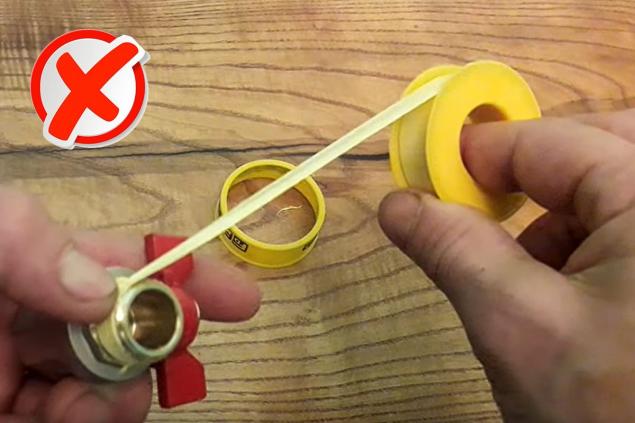

Many people wind the tape with the inner side, doing it out of habit, as if using a Band-Aid or Scotch. However, with this position, the fume is much faster unwinded from the coil than it manages to wind itself onto the pipe. Because of this, the tape begins to sag and twist, and it becomes increasingly difficult for you with each turn to carefully wind it onto the thread.

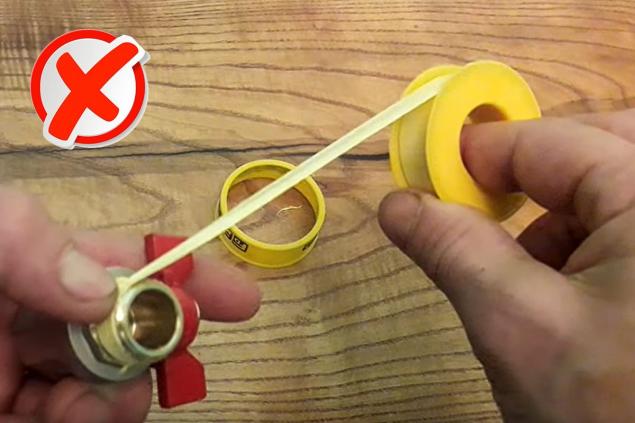

Incorrect position of the coil It is much more convenient to turn the coil and roll the fume with the outside. So the tape does not sag, and as it unwinds it is very convenient to stretch. It seems like a small thing, and saves a lot of time and nerves!

The correct position of the coil How many turns of fum tape should be wound on the thread? The number of turns depends on the thickness of the tape. In most cases, a layer of 1 mm is sufficient. This means that for a relatively thick tape with a thickness of 0.2 mm, five turns will suffice, and a hammer with a thickness of 0.1 mm will need to be wound ten times.

The carving with the coiled fume should be screwed into its connection with a tangible effort. When connecting metal parts, the pull should be done with a key.

For repairing which connections is better to use fume tape? It is rational to use fumes in such cases:

It should be understood that fume tape is not a panacea. If the connection you collected after tightening you need to turn in the opposite direction, the sealed properties of the fumki will be violated. We'll have to sort it out and rewind the tape. In such cases, it is better to use for sealing the good old bagel or plumbing thread.

How to wrap fume tape How to wind fume tape? First of all, remember that the tape must be wound in the direction of the thread. Otherwise, when twisting the connection, it simply peels off and will not be able to ensure tightness. Simply put, in 99% of cases, you need to roll the tape clockwise.

Slightly stretch the tape and wind it so that it tightly covers the thread.

Also thin tape can be stretched to the state of thread. Sweat this thread of the groove of the thread, then slightly loosen the tension and already the entire width of the tape fix the resulting seal.

By the way, even the position of the coil matters. Although the tape is absolutely the same from above and below, it is much more convenient to wind it with the outer (upper) side.

Many people wind the tape with the inner side, doing it out of habit, as if using a Band-Aid or Scotch. However, with this position, the fume is much faster unwinded from the coil than it manages to wind itself onto the pipe. Because of this, the tape begins to sag and twist, and it becomes increasingly difficult for you with each turn to carefully wind it onto the thread.

Incorrect position of the coil It is much more convenient to turn the coil and roll the fume with the outside. So the tape does not sag, and as it unwinds it is very convenient to stretch. It seems like a small thing, and saves a lot of time and nerves!

The correct position of the coil How many turns of fum tape should be wound on the thread? The number of turns depends on the thickness of the tape. In most cases, a layer of 1 mm is sufficient. This means that for a relatively thick tape with a thickness of 0.2 mm, five turns will suffice, and a hammer with a thickness of 0.1 mm will need to be wound ten times.

The carving with the coiled fume should be screwed into its connection with a tangible effort. When connecting metal parts, the pull should be done with a key.

For repairing which connections is better to use fume tape? It is rational to use fumes in such cases:

- for connecting plastic threaded connections;

- for fine and fine metal threads (experienced plumbers rarely use fume tape on pipes larger than an inch in diameter);

- for temporary repair of rubber sealing rings and gaskets, if there are no similar ones at hand for replacement;

- for temporary plumbing structures (for example, if you need to lengthen the garden hose).

It should be understood that fume tape is not a panacea. If the connection you collected after tightening you need to turn in the opposite direction, the sealed properties of the fumki will be violated. We'll have to sort it out and rewind the tape. In such cases, it is better to use for sealing the good old bagel or plumbing thread.

Why on the night of July 6-7 you can not sleep and other bans on Ivan Kupala

Casino – interesting facts