583

Small reactors as an alternative to modern power reactor units

Small modular reactors – one of the most popular directions of development of nuclear power and reactor technologies.

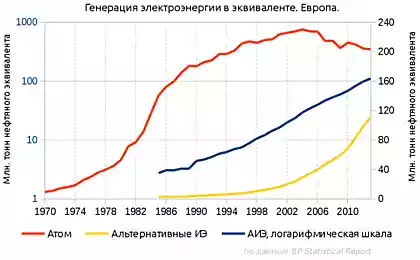

Over 70 years of nuclear power reactors has taken a strong position in the global balance of electricity production. Their capacity has increased from a few megawatts to nearly two gigawatts (although there have been projects and larger).

Modern nuclear power station is not only the unit, where there is a reactor plant and the turbine generator. It is oriented cluster of workshops and production employees to ensure work of such a powerful unit at the proper level. Think about it: at any nuclear power plant there is not only a large number of safety systems (which, by the way, obey the principle of redundancy) but also systems of support and ensure these safety systems. About the number and variety of systems for normal operation, just keep quiet.

The number of personnel at these facilities averages about 1,000 people at the power plant. But if at the NPP site can be additional production, for example, a complex on processing of radioactive waste, a separate storage of spent fuel or even desalination plant, the number of staff will only increase.

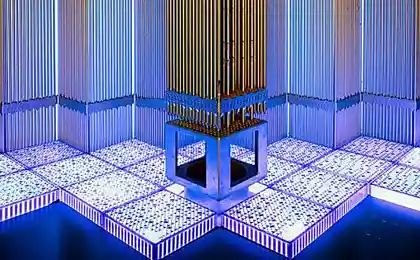

NPP Bruce (Canada) — 6232 MW (e). The photo shows a plant for production of heavy water.

It would seem that if the plant economically feasible and generates large amounts of electricity, what's the catch?

Modern nuclear power plants, large industrial complexes, there are significant drawbacks. First and foremost is the huge cost of the construction of such a complex. For example, the cost of construction of power unit No. 3 nuclear power plant Olkiluoto was changed from 3 to 8.5 billion dollars (it is necessary to consider the fact that some providing workshops and qualified personnel at the station already exists). For comparison, the cost of a TANK amounted to 6 billion dollars.

For the operation and maintenance of such giants require not only the operator but also the Supervisory body, a large number of institutes and research centers to support operation and safety.

In States with a small consumption of electric power by nuclear power stations in its present form will be uneconomical. I think readers can imagine how large the cost of waiting for the owners of nuclear plants after end of their useful life, when the station should be disassembled, recycled and packaging waste from electricity production at nuclear power plants. Experience shows that decommissioning of a large NPP is usually behind schedule.

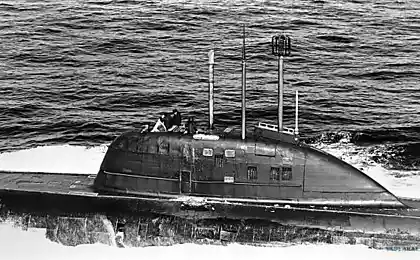

Another realityin Parallel with large power systems has developed dozens of systems for military programs, for example, reactors for submarines (up to 190 MW) and research reactors. All this gave impetus to the future development of small reactors.

So, what is it? The IAEA definition, "small" reactors with electric capacity of up to 300 MW, "medium" — up to 700 MW. However, "SMR" is most often used as an acronym for "small modular reactor" designed for repetitive construction, as an alternative to the complex construction of "nuclear island" with its awkward spaces and buildings.

MMP – small modular reactors – installation, designed using integrated technology (reactors with pumps (or without) and steam generators in one housing) that are manufactured in factories, using all the economic delights of mass production. They can be constructed independently from each other or as modules in a larger complex, with the addition of power gradually as needed.

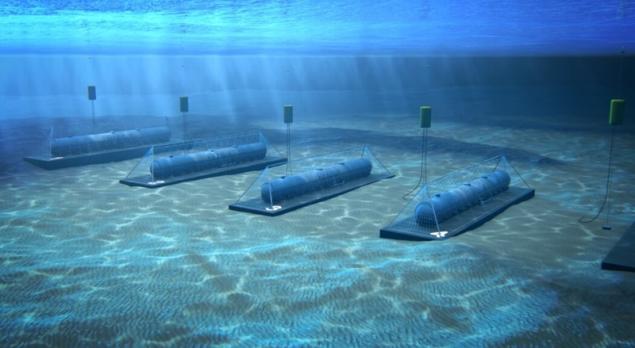

Be located small reactors can anywhere and everywhere.

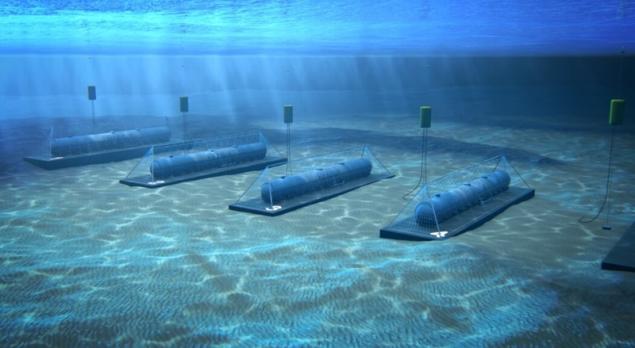

The Flexblue project – energy module placed under the water.

Russian military exotic concept.

The majority of MMR, when compared with large reactors are maloobsuzhdaemyj. In particular, projects such reactors would justify a longer interval between refueling (from 2 to 10 years versus 12 to 24 months larger units) or bookmark fuel generally in the entire life cycle – it is necessary periodically (once in 10 years or more) to replace the compact reactor module.

Main advantages:Smaller specific power reactor facility, a priori, makes it more secure from the point of view of intensity (less power, less residual heat after shutdown). From the point of view of the backend of the relatively low number of accumulated radioactive waste. Power plants of this type are less dependent on the availability of sampling of a large quantity of cooling water nearby. Thus perfectly suited for work in remote corners of the planet (and not only), for example, generating energy for mining. A sufficient number of passive safety systems. Good (in theory), these systems solve the main emergency problem is a loss of the ultimate heat consumer in case of an accident. In fact – though systems and passive, they also need constant supervision and maintenance. But it is necessary to recognize the greater stability of small RU to a typical situation – a complete loss of electrical power. Minimization of technically complex construction and installation works taking into account the specifics of regions of possible deployment. The minimum amount of maintenance. Reducing the number of necessary personnel in the field. The possibility of a substantial simplification of the procedure of decommissioning of these units. Small reactors with short term implementation (10 – 15 years) apply to the following types of reactors: PWR (pressurized-water pressure), fast neutron reactors or high temperature (mainly with gas coolant).

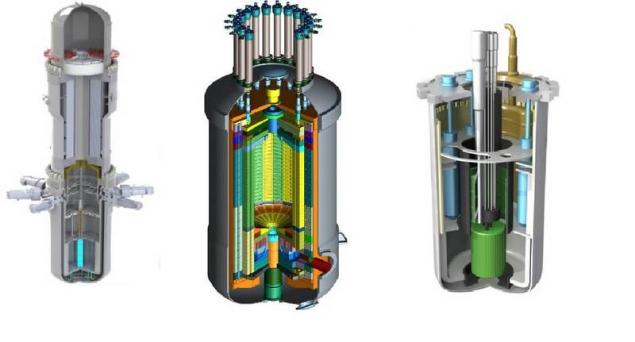

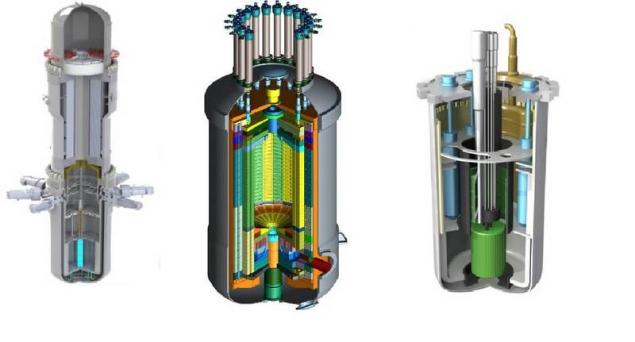

From left to right: 1 – pressurized water Westinghouse SMR. 2 – helium HTMR-100. 3 – fast PRISM.

Since most of the projects MMR is at the level of the concept and require significant R & d in the future in order to make concrete in my story, will focus on the two most relevant existing project.

1) NuScale (NuScale Power Inc., USA)

The project "NuScale Plant" formerly known as the MASLWR is a unit with a water reactor under pressure of small capacity – 45 MW(e).

It was developed jointly by the national engineering laboratory, Idaho, and Oregon state University (USA). In 2007 for the commercialization of the project has been created the company "NuScale Power Inc.". The development of the project since 2000. Since it is a modular reactor as standard on the platform, positioned 12 such modules.

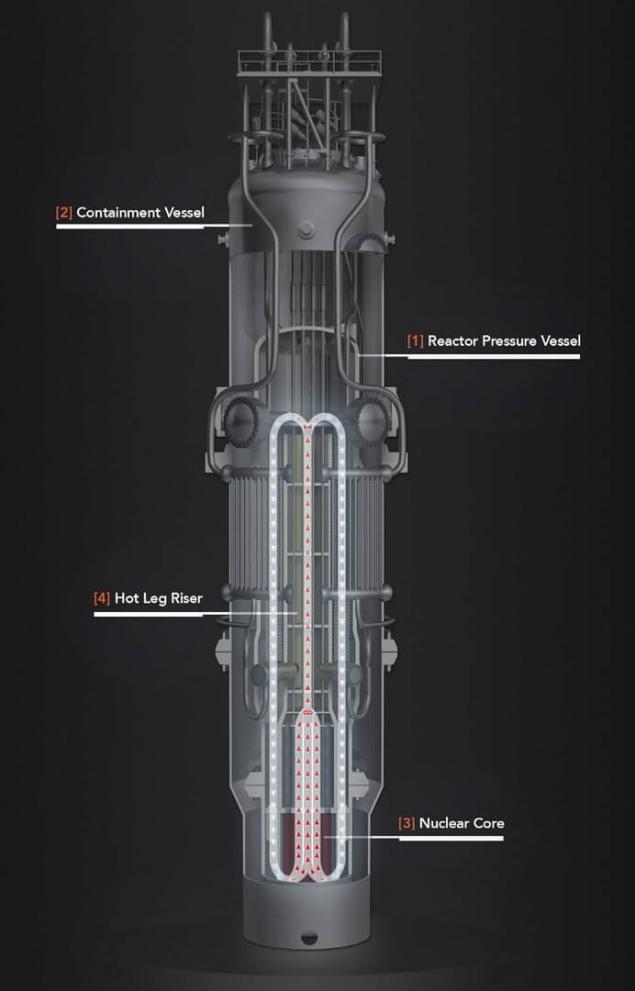

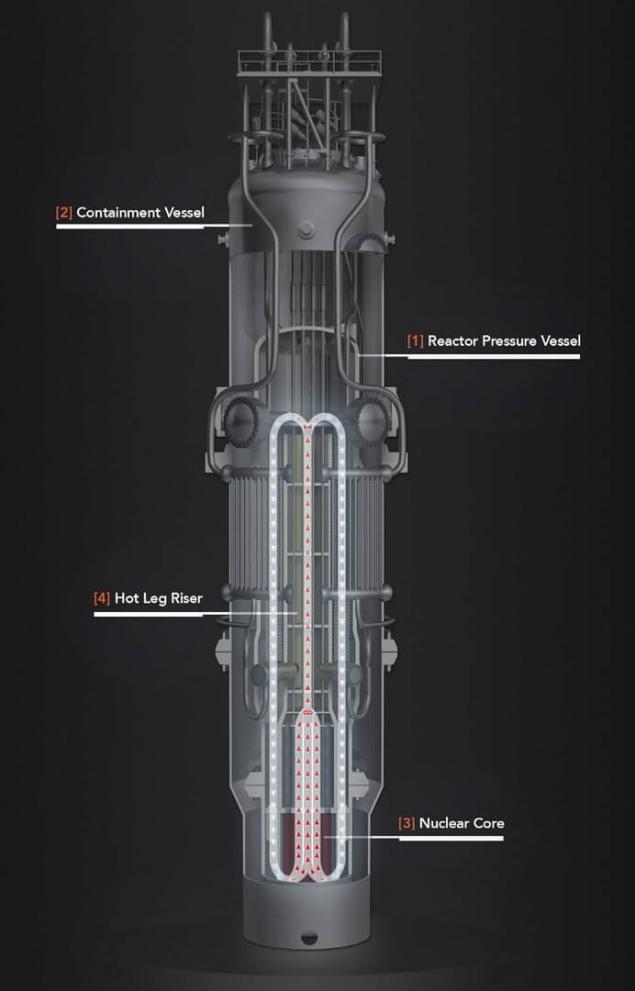

The reactor building is. Sectional view.

Core, steam generators and the pressurizer are within the same vessel, circulating pumps are not available. Case diameter is 2.9 meters, height of 17.4 meters.

The coolant heated in the core, moves up, gives off heat in the steam generator and downcomer channels back. Natural circulation, Yes.

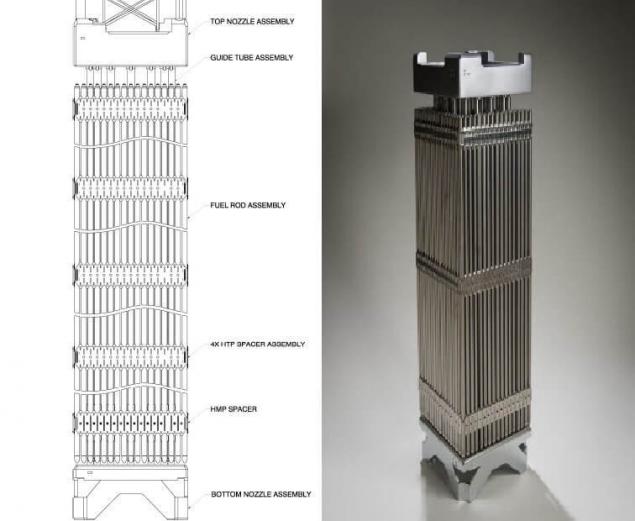

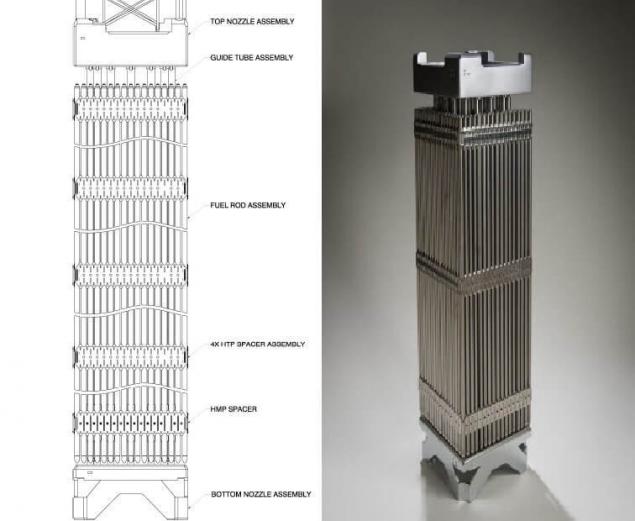

The active zone is assembled from fuel assemblies with the beautiful name NuFuel-HTP2. In fact, similar in design to the FA for the Western blocks of the PWR design. Technical specification for Assembly for the NRC here. Overload will be produced every 24 months.

NuScale fuel assemblies of the reactor. Incidentally, the production of AREVA.

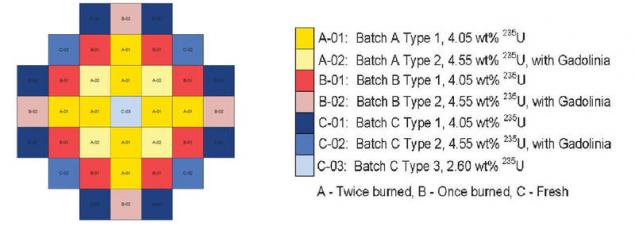

Download the cartogram of the reactor core NuScale.

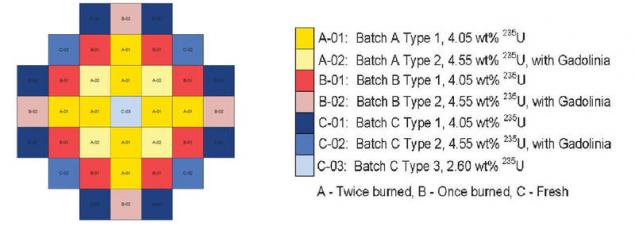

The main distinguishing feature from similar projects is that the reactor vessel is additionally placed in a thick-walled metal vessel made of stainless steel. This construction is placed in the pool, fully submerged in water. System decay heat removal consists of two independent passive systems.

A system of planned and emergency heat.

At the end of 2016, the company filed with the U.S. regulator an application for a license. This is the first application for a licence for the SMR in the United States. This fact means that at this stage the project is ready almost completely, and has the ability to become very real, sellable product.

2) CAREM-25 (CNEA, Argentina)

Probably, the reader never expected to see this country in the top developers of MMR, but Argentina is now closer to operating a 25-megawatt demonstration modular reactor.

CAREM-25 is an integral type PWR, the construction of which began in 2014 next to Atucha nuclear power plant. Pleasantly surprised that this Argentine technology, and 70% of the equipment and materials you plan to obtain from local producers.

The project is designed as a source of energy for electricity supply of regions with small consumption. Can also be used to run desalination plants.

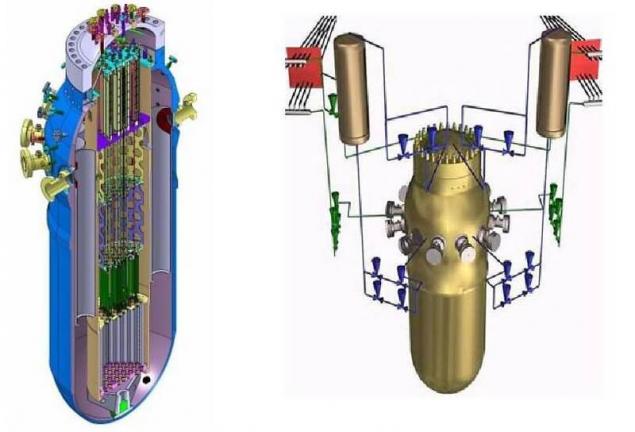

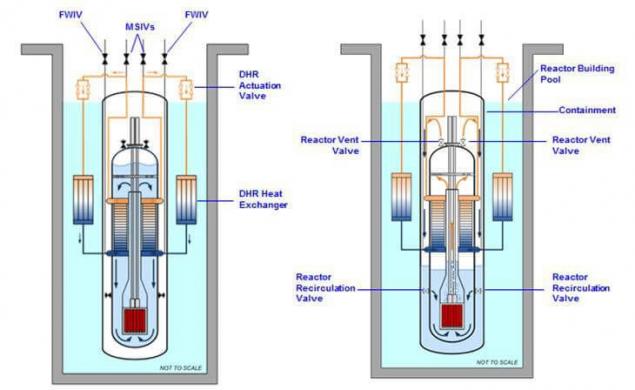

The reactor vessel and core system security.

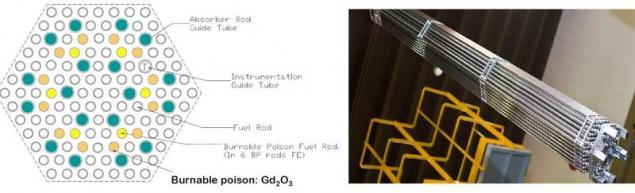

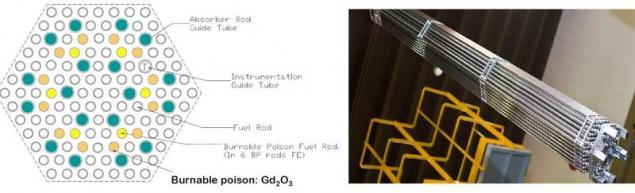

Active zone, hydraulic actuators, regulators, and twelve pyotrovich vertical steam (superheating) are located in one building – all the canons of modularity. In the first circuit for the natural circulation. The reactor vessel has a diameter of 3.2 meters and a height of 11 meters. The active zone are recruited from 61 hex (!) the fuel cartridge.

Fuel assemblies of the reactor CAREM-25.

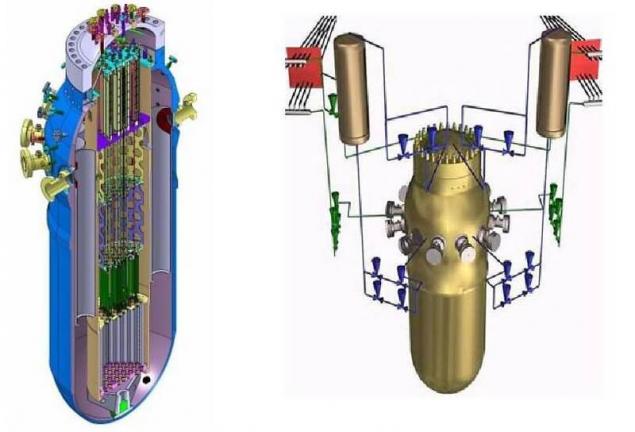

CAREM-25 is Packed with passive and simple active systems of safety. The project envisages that in a severe accident the active area remains intact for 36 hours without operator action and without external power supply. The expected frequency of core damage (CPAS)–10E-07 reactor/year.

Stop the fission chain reaction is performed using two independent systems, the control rods and injection of boron in the water. Under normal conditions, boron is not used.

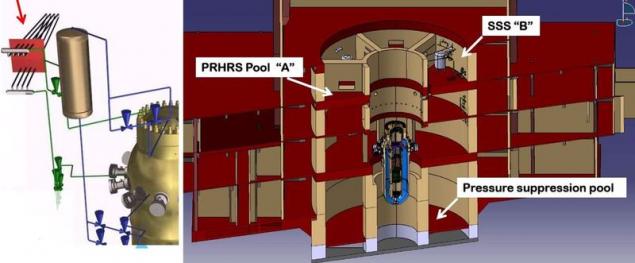

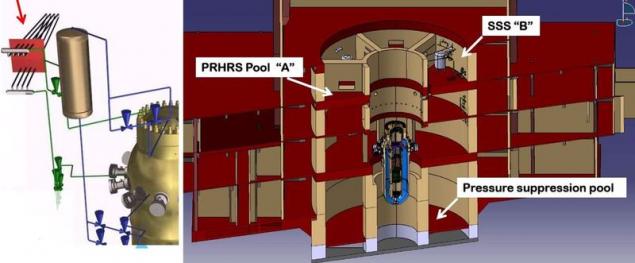

Removal of the residual energy is a passive system PRHRS. Works on the principle of technological condenser (isolation condenser). Capacitors PRHRS located in the basin at the top of the containment. The system provides heat removal from the active zone within 36 hours.

Technological condenser and pool systems PRHRS.

The project includes also a passive alarm system pouring water into the core of EIS in the case of reducing pressure in the housing is lower than 1.5 MPa – the pressure breaks pressure relief aperture, and housing filled with borated water from the tank system EIS. Simple – hydroelastic of the CECS.

The first loading is scheduled in 2018.

This project has a large number of questions. For example, the reliability of 12 in-vessel steam generators, inspection and repair.

And so it will look like the building of the unit outside.

As a conclusion, it is worth noting that small reactors will "recharge the motor of the" peaceful atom and to give the industry a new force, and less power, meaning shorter construction time will reduce the cost of generation and compete with the rising popularity of renewable energy.

At the end of 2016, a consortium was established to implement strategic objectives are to commence commercial operation of small reactors since mid 2020-ies. It is composed of the following companies: AREVA, Bechtel, BWXT, Dominion, Duke Energy, Energy Northwest, Fluor, Holtec International, NuScale Power, Ontario Power Generation, PSEG, TVA, and Utah Associated Municipal Power Systems. As you can see, there are several significant players.

So what about a bright future to speak while early, but the positive trend is still visible.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: geektimes.ru/post/286560/

Over 70 years of nuclear power reactors has taken a strong position in the global balance of electricity production. Their capacity has increased from a few megawatts to nearly two gigawatts (although there have been projects and larger).

Modern nuclear power station is not only the unit, where there is a reactor plant and the turbine generator. It is oriented cluster of workshops and production employees to ensure work of such a powerful unit at the proper level. Think about it: at any nuclear power plant there is not only a large number of safety systems (which, by the way, obey the principle of redundancy) but also systems of support and ensure these safety systems. About the number and variety of systems for normal operation, just keep quiet.

The number of personnel at these facilities averages about 1,000 people at the power plant. But if at the NPP site can be additional production, for example, a complex on processing of radioactive waste, a separate storage of spent fuel or even desalination plant, the number of staff will only increase.

NPP Bruce (Canada) — 6232 MW (e). The photo shows a plant for production of heavy water.

It would seem that if the plant economically feasible and generates large amounts of electricity, what's the catch?

Modern nuclear power plants, large industrial complexes, there are significant drawbacks. First and foremost is the huge cost of the construction of such a complex. For example, the cost of construction of power unit No. 3 nuclear power plant Olkiluoto was changed from 3 to 8.5 billion dollars (it is necessary to consider the fact that some providing workshops and qualified personnel at the station already exists). For comparison, the cost of a TANK amounted to 6 billion dollars.

For the operation and maintenance of such giants require not only the operator but also the Supervisory body, a large number of institutes and research centers to support operation and safety.

In States with a small consumption of electric power by nuclear power stations in its present form will be uneconomical. I think readers can imagine how large the cost of waiting for the owners of nuclear plants after end of their useful life, when the station should be disassembled, recycled and packaging waste from electricity production at nuclear power plants. Experience shows that decommissioning of a large NPP is usually behind schedule.

Another realityin Parallel with large power systems has developed dozens of systems for military programs, for example, reactors for submarines (up to 190 MW) and research reactors. All this gave impetus to the future development of small reactors.

So, what is it? The IAEA definition, "small" reactors with electric capacity of up to 300 MW, "medium" — up to 700 MW. However, "SMR" is most often used as an acronym for "small modular reactor" designed for repetitive construction, as an alternative to the complex construction of "nuclear island" with its awkward spaces and buildings.

MMP – small modular reactors – installation, designed using integrated technology (reactors with pumps (or without) and steam generators in one housing) that are manufactured in factories, using all the economic delights of mass production. They can be constructed independently from each other or as modules in a larger complex, with the addition of power gradually as needed.

Be located small reactors can anywhere and everywhere.

The Flexblue project – energy module placed under the water.

Russian military exotic concept.

The majority of MMR, when compared with large reactors are maloobsuzhdaemyj. In particular, projects such reactors would justify a longer interval between refueling (from 2 to 10 years versus 12 to 24 months larger units) or bookmark fuel generally in the entire life cycle – it is necessary periodically (once in 10 years or more) to replace the compact reactor module.

Main advantages:Smaller specific power reactor facility, a priori, makes it more secure from the point of view of intensity (less power, less residual heat after shutdown). From the point of view of the backend of the relatively low number of accumulated radioactive waste. Power plants of this type are less dependent on the availability of sampling of a large quantity of cooling water nearby. Thus perfectly suited for work in remote corners of the planet (and not only), for example, generating energy for mining. A sufficient number of passive safety systems. Good (in theory), these systems solve the main emergency problem is a loss of the ultimate heat consumer in case of an accident. In fact – though systems and passive, they also need constant supervision and maintenance. But it is necessary to recognize the greater stability of small RU to a typical situation – a complete loss of electrical power. Minimization of technically complex construction and installation works taking into account the specifics of regions of possible deployment. The minimum amount of maintenance. Reducing the number of necessary personnel in the field. The possibility of a substantial simplification of the procedure of decommissioning of these units. Small reactors with short term implementation (10 – 15 years) apply to the following types of reactors: PWR (pressurized-water pressure), fast neutron reactors or high temperature (mainly with gas coolant).

From left to right: 1 – pressurized water Westinghouse SMR. 2 – helium HTMR-100. 3 – fast PRISM.

Since most of the projects MMR is at the level of the concept and require significant R & d in the future in order to make concrete in my story, will focus on the two most relevant existing project.

1) NuScale (NuScale Power Inc., USA)

The project "NuScale Plant" formerly known as the MASLWR is a unit with a water reactor under pressure of small capacity – 45 MW(e).

It was developed jointly by the national engineering laboratory, Idaho, and Oregon state University (USA). In 2007 for the commercialization of the project has been created the company "NuScale Power Inc.". The development of the project since 2000. Since it is a modular reactor as standard on the platform, positioned 12 such modules.

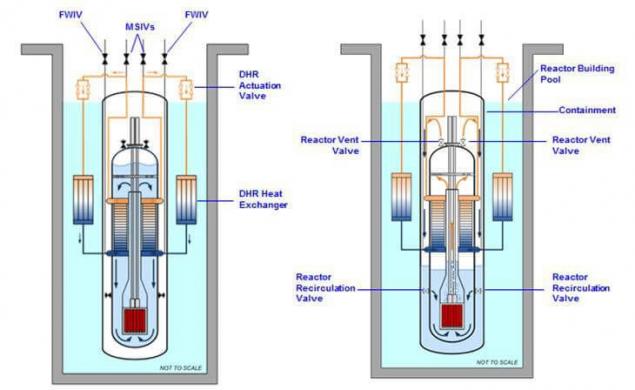

The reactor building is. Sectional view.

Core, steam generators and the pressurizer are within the same vessel, circulating pumps are not available. Case diameter is 2.9 meters, height of 17.4 meters.

The coolant heated in the core, moves up, gives off heat in the steam generator and downcomer channels back. Natural circulation, Yes.

The active zone is assembled from fuel assemblies with the beautiful name NuFuel-HTP2. In fact, similar in design to the FA for the Western blocks of the PWR design. Technical specification for Assembly for the NRC here. Overload will be produced every 24 months.

NuScale fuel assemblies of the reactor. Incidentally, the production of AREVA.

Download the cartogram of the reactor core NuScale.

The main distinguishing feature from similar projects is that the reactor vessel is additionally placed in a thick-walled metal vessel made of stainless steel. This construction is placed in the pool, fully submerged in water. System decay heat removal consists of two independent passive systems.

A system of planned and emergency heat.

At the end of 2016, the company filed with the U.S. regulator an application for a license. This is the first application for a licence for the SMR in the United States. This fact means that at this stage the project is ready almost completely, and has the ability to become very real, sellable product.

2) CAREM-25 (CNEA, Argentina)

Probably, the reader never expected to see this country in the top developers of MMR, but Argentina is now closer to operating a 25-megawatt demonstration modular reactor.

CAREM-25 is an integral type PWR, the construction of which began in 2014 next to Atucha nuclear power plant. Pleasantly surprised that this Argentine technology, and 70% of the equipment and materials you plan to obtain from local producers.

The project is designed as a source of energy for electricity supply of regions with small consumption. Can also be used to run desalination plants.

The reactor vessel and core system security.

Active zone, hydraulic actuators, regulators, and twelve pyotrovich vertical steam (superheating) are located in one building – all the canons of modularity. In the first circuit for the natural circulation. The reactor vessel has a diameter of 3.2 meters and a height of 11 meters. The active zone are recruited from 61 hex (!) the fuel cartridge.

Fuel assemblies of the reactor CAREM-25.

CAREM-25 is Packed with passive and simple active systems of safety. The project envisages that in a severe accident the active area remains intact for 36 hours without operator action and without external power supply. The expected frequency of core damage (CPAS)–10E-07 reactor/year.

Stop the fission chain reaction is performed using two independent systems, the control rods and injection of boron in the water. Under normal conditions, boron is not used.

Removal of the residual energy is a passive system PRHRS. Works on the principle of technological condenser (isolation condenser). Capacitors PRHRS located in the basin at the top of the containment. The system provides heat removal from the active zone within 36 hours.

Technological condenser and pool systems PRHRS.

The project includes also a passive alarm system pouring water into the core of EIS in the case of reducing pressure in the housing is lower than 1.5 MPa – the pressure breaks pressure relief aperture, and housing filled with borated water from the tank system EIS. Simple – hydroelastic of the CECS.

The first loading is scheduled in 2018.

This project has a large number of questions. For example, the reliability of 12 in-vessel steam generators, inspection and repair.

And so it will look like the building of the unit outside.

As a conclusion, it is worth noting that small reactors will "recharge the motor of the" peaceful atom and to give the industry a new force, and less power, meaning shorter construction time will reduce the cost of generation and compete with the rising popularity of renewable energy.

At the end of 2016, a consortium was established to implement strategic objectives are to commence commercial operation of small reactors since mid 2020-ies. It is composed of the following companies: AREVA, Bechtel, BWXT, Dominion, Duke Energy, Energy Northwest, Fluor, Holtec International, NuScale Power, Ontario Power Generation, PSEG, TVA, and Utah Associated Municipal Power Systems. As you can see, there are several significant players.

So what about a bright future to speak while early, but the positive trend is still visible.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: geektimes.ru/post/286560/

Urn tetraBIN makes the disposal of garbage in the game

Volvo Concept Truck: a truck with a hybrid power plant