423

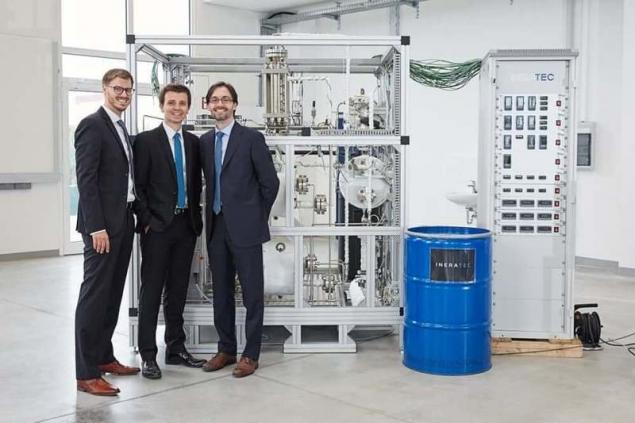

A reactor that produces liquid fuels from CO2

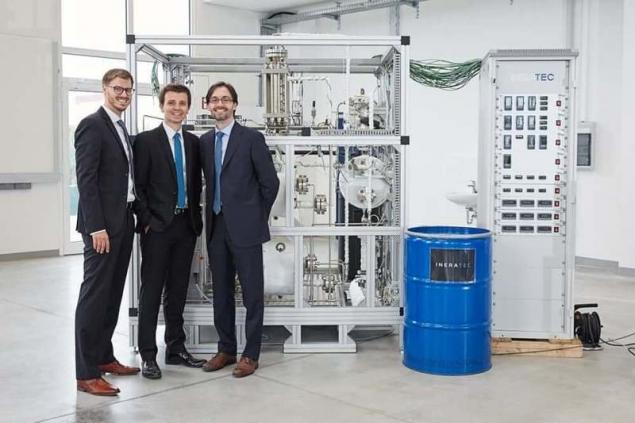

When we burn fuels emits huge amount of CO2 that contribute to climate change. The new compact power plant designed in Germany may help to overcome the problem of emissions by converting carbon dioxide into usable fuels.

There are already slozhnosmeshannye installations that recycle CO2 into methanol and ethanol, but the installation Soletair can go much further.

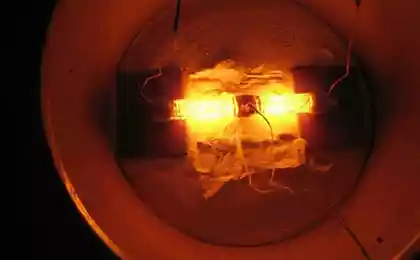

The first major advantage of the system is that it is initially compact and fits in the container, such benefits, the experts were able to achieve thanks to microscopic device the internal system.

Another somewhat dubious, plus that the production of any fuel, diesel, gasoline, kerosene. This is an interesting point, as the system will work in some way on itself, it will first absorb the effects of gasoline engine, and then will fill the same petrol engine, again to take CO2 from the atmosphere to create a new gasoline.

The reactor can also be configured for processing small amounts of methane.

"We delivered a completely new, modular technology that is a viable alternative to expensive large chemical facilities, used for the ordinary production-type gas-liquid," says Tim Bolden of Ineratec. He also explained that the system could eventually be used for collecting gas from sewage treatment plants or be used on organic farms.

Pilot plant commissioned in one of the technological centres of Finland, in 2017 will still pass the system test, and in 2018 it will be on the market.published

via

Source: ecotechnology

There are already slozhnosmeshannye installations that recycle CO2 into methanol and ethanol, but the installation Soletair can go much further.

The first major advantage of the system is that it is initially compact and fits in the container, such benefits, the experts were able to achieve thanks to microscopic device the internal system.

Another somewhat dubious, plus that the production of any fuel, diesel, gasoline, kerosene. This is an interesting point, as the system will work in some way on itself, it will first absorb the effects of gasoline engine, and then will fill the same petrol engine, again to take CO2 from the atmosphere to create a new gasoline.

The reactor can also be configured for processing small amounts of methane.

"We delivered a completely new, modular technology that is a viable alternative to expensive large chemical facilities, used for the ordinary production-type gas-liquid," says Tim Bolden of Ineratec. He also explained that the system could eventually be used for collecting gas from sewage treatment plants or be used on organic farms.

Pilot plant commissioned in one of the technological centres of Finland, in 2017 will still pass the system test, and in 2018 it will be on the market.published

via

Source: ecotechnology

6 vital skills which are not taught in high school

James Rhodes: Find what you love and let it kill you