261

Fuel cells for domestic use

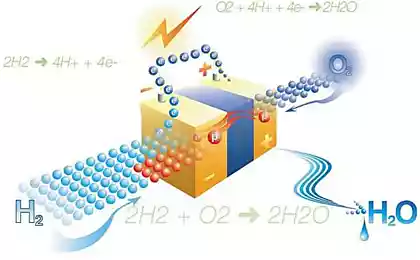

Fuel cells convert chemical energy directly into electricity, bypassing preliminary transformations.

Despite the obvious performance benefits, elements did not cause a furore in the market immediately after the invention due to their complexity. But green technology is evolving.

Researchers from the Fraunhofer Institute and Vaillant have developed a simple device available for household use.

“We should always talk about a fuel cell system,” says Dr. Matthias Jahn, head of modules and systems at the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) in Dresden.

One cell produces a small voltage, not enough to power the facilities. Therefore, by analogy with batteries, several fuel cells are combined into a single system. Each fuel cell is the size of a CD. “We call groups [of elements] stacks,” explains Dr. Yang.

Fuel cells convert natural gas directly into electricity. They are much more efficient than internal combustion engines that use multiple conversion steps.

First, the energy released as a result of burning fuel is converted by the engine into mechanical energy, through which the shaft of the electric generator rotates. As a result of the chain of transformation, most of the energy is lost.

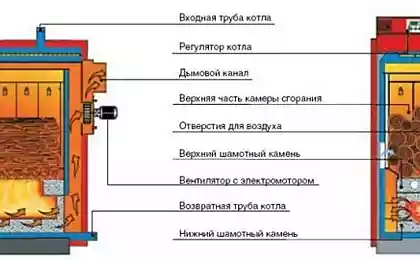

Together with renowned heating equipment manufacturer Vaillant, the Fraunhofer Institute has developed a compact, safe and reliable fuel cell system that generates electricity and heat for private households from natural gas. Currently, the device is undergoing practical test operation in private households.

Its size home fuel cell power plant, adapted for wall installation, does not differ from conventional heating boilers, however, produces not only heat, but also electrical energy. The power output is 1 kW, which is enough to meet the needs of an average family of 4 people.

As part of the European demonstration project ene.field, about 150 such power units have been installed in a number of EU countries. In addition, in early 2014 Valliant began their small-scale production.

The fuel elements of a miniature home power plant are technologically different from those used primarily in cars.

Oh.Main operational difference in the degree of heating. If the operating temperature of automotive fuel cells on the proton exchange membrane reaches 80 degrees, then the solid fuel cell technology used by researchers from the Fraunhofer Institute involves heating up to 850 degrees. However, solid elements are cheaper and easier. As an electrolyte, they use ceramics, which does not contain precious and rare metals.

The source of electrical energy at the outlet of fuel cells is hydrogen. When connecting the plant to the natural gas network, before feeding into the silent cold combustion chamber, where electricity and heat are produced during the reaction with oxygen, natural gas undergoes a reforming stage, enriched with hydrogen.

Source: facepla.net

The electric scooter is the future of roads

5 tips doctors how to cope with summer aggravation of varicose veins