190

Structural battery as an element of the car body

As you know, electric cars were born before gasoline cars. But the latter took a leading place among mechanical transport due to higher mobility. Heavy batteries did not allow environmentally friendly electric transport to compete with smoking and thundering internal combustion engines. Modern lithium-ion batteries are much lighter and more compact than the analogues of the last century, but still unable to provide electric cars with the mileage available to gasoline cars.

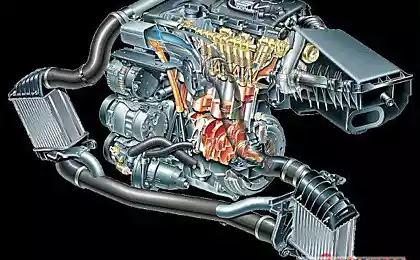

How to change the situation and reduce the weight of electric vehicles? One of the solutions offered by researchers from the Swedish Royal Institute of Technology KTH (Kungliga Tekniska högskolan). In their opinion, it is possible to reduce weight by using batteries as load-bearing elements of the body structure.

Large batteries are needed to store enough energy for a long journey. But the larger the batteries, the greater their weight, the greater the energy consumption for their transportation. This logical connection can be broken if the batteries replace the structural elements of the body and cease to be “overweight”.

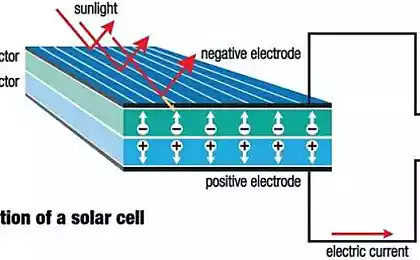

Scientists from KTH have found a promising solution by developing carbon fiber with the right properties. According to Eric Jacques, a researcher who develops materials for automotive and aerospace technology, carbon fiber can perform two functions simultaneously. As a lightweight composite material, it can be used for the manufacture of body parts and at the same time can serve as active electrodes of lithium-ion batteries.

“The goal of our study was to develop a structural battery consisting of multifunctional lightweight materials that simultaneously resist mechanical stress and store electrical energy,” said Jacques. This can lead to a reduction in the weight of electric vehicles. According to the researcher, carbon fiber offers a viable alternative to graphite. Lithium can be integrated into microfibers with good conductivity. This is possible due to the specific properties of the material developed in KTH. Carbon fibers are very lightweight, have a stable continuous structure and excellent mechanical properties.

"The research project has shown very good results, but we still have some work to do before we can introduce the finished batteries," Jacques said.

Three KTH professors are collaborating on the project: Göran Lindbergh – Chemical Engineering, Mats Johansson – Fiber and Polymer Technologies and Dan Zenkert – Aviation and Transport Engineering. Swerea SICOMP Research Institute and Luleå Institute of Technology are also involved.

Professor Johansson believes that the main direction of research is to improve the mechanical properties of batteries, so that they not only store and store energy, but also become part of the design of an electric car. “For example, the hood of a car can become part of a battery,” says Johansson, adding that such a combination of functions is possible not only in cars, but also in other electronic devices.

Source: facepla.net