426

Foam glass is an insulator of new generation

Alex Wilson, founder and chief editor of the authoritative network the publication Environmental Building News, in October 2010 began one of his editorial articles with the phrase: "I have a new favorite insulation material". He talked about the foam glass.

The thing is that the foam glass material is not new. In the world, its production started in the 40-ies of the last century in the United States, and even the Soviet Union in the 70s was released in the year of the order of 100 000 cubic meters of foam glass – however, do not differ high quality. Therefore, architects with experience of him must have heard, though it is hardly seen and certainly wasn't ready to share the enthusiasm Alex Wilson: in the USSR, the foam glass was solely used as filler for concrete and backfilling.

Its main value consisted in the fact, allowing the glassworks to get rid of the fight and marriage (Gomel glass factory and so far only kept to yourself such production). In the world as a major application of foamed glass industrial insulation. However, in recent decades the foam glass is increasingly penetrated into the building: first in Europe and then in USA.

Not afraid of anything

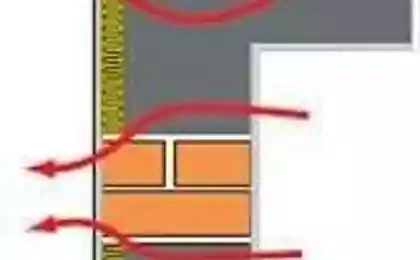

Why? Imagine hard (tensile strength in compression of 0.7-4 MPa, bending of 0.4 – 0.6 MPa), graphite-colored porous blocks, resembling in cross-section of a sponge or fine pumice stone, but with cells much smaller, and most importantly – about the same size and evenly fill the entire thickness of the block. Since the material from which the blocks ultimately nothing like a special way and frozen foam glass, all the basic physical properties of the foam glass inherited from the "parent".

Primarily interested in water vapor permeability. It lies in the range from 0 to 0.005 mg/(m h PA) – simply put, foam glass, like ordinary glass, undamaged water vapour does not pass at all. Water absorption is also close to zero: moisture sorption of foam glass – 0,2-0,5%. Naturally the foam does not rot, is not afraid of rodents, microorganisms, and even the most aggressive environments. The effective range of temperatures – from -260°C to +500°C. But high-performance insulation foam glass does not material, and foam structure. At a density of 110 to 200 kg/m its thermal conductivity is only 0,04-0,08 W/(m·K). Good and noise reduction: up to 56 DB.

Extra points for green standards

And now add that from this material you can do the facing blocks of various configuration, which blocks these for installation on the protected surface, as a rule, do not require special fastening systems that they are easily sawn using an abrasive wheel or a fine hacksaw, processed and polished. Their installation does not require highly skilled workers.

They are environmentally inert, their service life is calculated for decades, and when you do decide to break the house in which the insulation is made of foam glass, appraisers for LEED or BREEAM will be happy to award you extra rating points because the foam glass allows 100% recycling.

The details of the case

Now I understand why Alex Wilson came in so excited? However any, even the most advanced material has its own peculiarities and subtleties that should be considered. Foam glass is no exception. First, you should avoid styling it without external protective waterproofing: and that the blocks of foam glass is not pressed under the feet of those who will later go up on the roof, if we are talking about roofs, and to avoid the ingress of moisture into the open cells of the outer layer during operation. Freezing water can break them, the blocks have cracks.

Secondly, I must admit that the foam glass quality – but this makes sense to use for insulation – material is not cheap. One cubic meter of foam glass, even Chinese, presented on our market, not to mention American, Belgian or Czech, is about 4-5 times the price of a cubic meter of mineral wool or polystyrene, the two most common competitors.

However, the situation is improving, the fact that the total consumption of materials in one "square" – including concrete for screed – if you are using the foam glass is lower than for mineral wool, which greatly reduces the price gap. Educated investor the cost estimate will consider it as the fact that the rate of installation of foam glass above, and therefore, labor will be cheaper. Simpler and construction under the veneer, as there is no need to worry about ventilation of the insulation layer. Finally, operating costs for thermal insulation of foam glass is much lower.

In General, the foam glass as if specially designed for modern energy-efficient and passive houses, where ideologically preferably once to invest in a thick and warm walls and floors, then the rest of my life to save on energy.

The construction material for green building made in Russia!

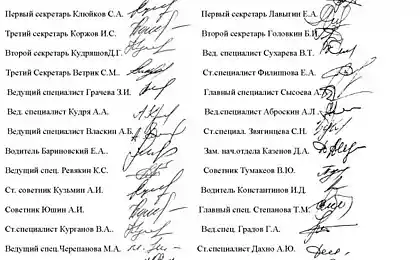

In Russia just in time to resume their own production of foam glass. Under the "neoporm" it at the factory in Vladimir starts the company "STES-Vladimir". The Department of development and sales in Moscow say that the neoporm foam glass is manufactured by our own original and proprietary recipes and special technology and quality raw material is used only first-class battle flat window glass Russian glass factories (one more reason to celebrate "green": recycling glass because of the fight – a severe environmental problem).

The company promises the first commercial batch of high-quality Russian glass foam by the middle of 2014. Then followed all kinds of shaped products of technical appointment, and a year – granules of foamed glass, for filling of concrete.

source:green-city.su

Source: /users/1077

The devil rocks Carl-Carl in Australia

Five great movies about unrequited love, which you may have missed