649

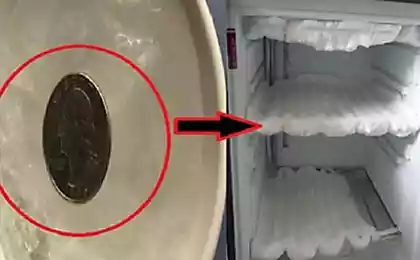

Their hands: Cellar glacier —dry freezer all year round

For Russia, harvesting for the future and laying on the storage of food for long periods of time predetermined by its geographical location. Pickles, vegetables and jams, as a rule, develop in the cellar, which is arranged under the house, in the garage or in one of the home buildings

But with the storage of meat and fish products requiring refrigeration, there is some problem, especially in the summer.

Long cellar glacier were arranged according to the scheme applied in the winter the ice in a specially prepared room. As a rule, a pit or cellar. And, depending on the outside air temperature in spring and summer at a certain time, to extend the shelf life of the workpieces. Thus, dirt and a large damp in the room not to avoid labor invested a lot, but freezing temperatures in the cellar are kept small.

I propose to build a cellar with his hands. Rather, it's not even a cellar, and cellar to the glacier — a true freezer year-round and preserving by the end of summer, the temperature of minus 10 — 15 degrees.

Temperature of minus 10 degrees is enough for freezing and storage in the cellar of any products requiring refrigeration. Cellar glacier of this design over the winter period, attains and will securely hold freezing temperatures even in the southern regions of Russia.

Look at the circuit cellar of the glacier in the picture and you will understand a short description of the device and principle of work.

Cellar-glacier it is possible to arrange in the yard under a natural or artificial hill, with the device direct entry, under the floor of the garage or any other buildings in the yard. The dimensions of the cellar of the glacier and the input device are selected individually depending on need.

The cellar device follows from the principle of work is as follows: the perimeter of the bottom areas of the glacier are covered with a frame, welded from metal pipes with a diameter of 80-100 mm.

In the middle of the frame are welded two hard pipes of the same diameter. The height of risers should be such that above the earth's surface, after filling with soil, remained 30-50 centimeters.

Thus obtained, the reservoir is filled with kerosene. On protruding from the ground, pipes in the summer to put on a seat made of foam and covered with a thick cloth or leatherette, winter covers are removed.

The principle of operation of the cellar of the glacier is in the accumulation of cold in the winter and storing it in the warm season. In this cellar you can safely keep meat and fish products throughout the year.

Why kerosene is selected as the filler pipes cooling the cellar? Because kerosene is a unique liquid which has a number of advantages for this application:

- kerosene does not allow to rust the pipes from the inside;

- kerosene has a low coefficient of thermal conductivity, which is the main reason for its choice;

- temperature of the active evaporation about 600 degrees, and the temperature of crystallization is equal to minus 60 degrees. This temperature range indicates that the kerosene practically does not evaporate under normal conditions. Hence conomie time and money;

- the cost of kerosene is almost two times less than the transformer oil, traditionally used to fill the radiators of transformers in power grids.

Incidentally, the crystallization temperature of transformer oil is equal to minus 45 degrees. Approximately the same ratios in these fluids and the time of service.

Apply kerosene should be technical. Better aircraft. In paartronic settlements may be the opportunity to purchase kerosene at the airport of "settling" for less high price.

The procedure of manufacturing the cellar of the glacier.

Dig with your hands or with the help of technology a hole bigger than required size 80-100 cm in width and length, and 40-50(cm) in depth. If You decide to make a dirt floor, not concrete, the height of the cellar do not need to increase by the specified amount.

The selection was made depending on the depth of location of ground water. Then welded to produce a container of kerosene from the pipes, which should be 15cm from the sides of the pit.

Hence, the thickness of the walls of the cellar: external pipe diameter plus 30 inches. Precision is not needed, the principle is important — the larger the mass of concrete, the stronger freezer cellar. That is, the more she accumulates the cold. The presence of kerosene, embedded in a concrete wall of the glacier, can significantly slow down the process of heat transfer from cold concrete to a warm soil and air in the summer.

A serious drawback of the use of kerosene may be that, with poor welding or violation of the integrity of the pipes over time from rust on the outside, it has a strong smell and can seep through tiny pores and cracks in concrete.

Source: vk.com/praviladeneg