194

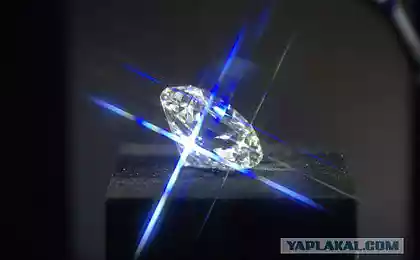

Scientists managed to capture shock waves propagating in a diamond crystal

It turns out that extreme impacts can cause shock waves that propagate inside the crystal of one of the hardest and most durable materials in the world – diamond. And scientists from the German research organization Deutsches Elektronen-Synchrotron (DESY) managed to capture the process of propagation of such shock waves using ultrashort pulses of X-ray radiation. These extremely bright and brief flashes of X-rays allowed scientists to track all the dynamic changes in the diamond crystal lattice that occur during the shock wave. In addition, the resulting sequence of images had an extremely high temporal and spatial resolution. “Our experiment opens the door to a completely new scientific field,” says Dr. Andreas Schropp, who worked in the group led by Professor Christian Schroer, “We used high-speed radiography to determine the quantitative changes in the local properties of the crystal and the dynamic changes in the structure of matter under the influence of extreme influences.”

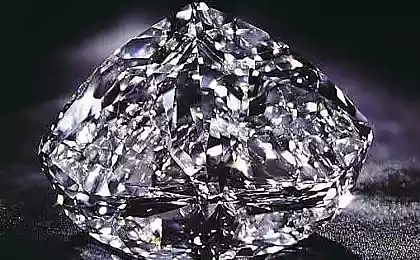

The researchers used the world’s strongest X-ray laser, the Linac Coherent Light Source LCLS, at the SLAC National Linear Accelerator Laboratory. The researchers installed a diamond strip, 3 centimeters long and 0.3 millimeters thick in a special holder. The shock wave was initiated in the diamond by a short flash of an infrared laser that focuses on the thin face of the crystal. The pulse lasted only 150 picoseconds and contained a power of 12 trillion watts per square centimeter. The resulting shock wave passed through the diamond crystal, moving at a speed of 72 thousand kilometers per hour.

“To get images of such rapid processes requires the use of a source of extremely short periods of time,” explains Dr. Shropp, “This source was the LCLS X-ray laser, whose pulse has a duration of only 50 femtoseconds, which allows you to capture even the fastest movements. Using X-ray microscopy allowed to obtain a resolution of about 500 nanometers per pixel.

However, each laser "shot" completely destroys the test material sample. So we had to repeat the experiment with identical samples, making one frame of the image at a time. And as a result, we collected from the images a complete video showing the process of the shock wave passing through the diamond crystal.”

Using the obtained video, the scientists were able to determine the quantitative changes in the density of the material during the passage of the shock wave. The analysis showed that the shock wave compresses diamond by about 10 percent, and such deformation can not withstand even the most durable material in the world.

“Due to the fact that diamond has a lot of distinguished physical properties, it is a very useful material both in some research and from a technological point of view,” says Professor Jerome Hastings (Prof. Jerome Hastings) from the SLAC laboratory, “and further study of the properties of this material will significantly expand the areas of its application.”

Scientists expect that the improvement of X-ray lasers and the optimization of the sensors used will allow them in the future to increase the spatial resolution to 100 nanometers per pixel. This will be possible after the commissioning of the new European X-ray laser XFEL, which is currently under construction. Due to the pervasive nature of X-rays, this technology can be used to study any solid material, including metals.

“Such a method of research could yield a great deal of a new field of science called materials science. And, as you know, this science determines a lot that we come into contact with literally every day. It is likely, although it will not be so noticeable, the methods developed by us may have an impact on our lives in the future, concluded Dr. Shropp.

P.S. And remember, just changing our consumption – together we change the world!

Source: www.dailytechinfo.org

The researchers used the world’s strongest X-ray laser, the Linac Coherent Light Source LCLS, at the SLAC National Linear Accelerator Laboratory. The researchers installed a diamond strip, 3 centimeters long and 0.3 millimeters thick in a special holder. The shock wave was initiated in the diamond by a short flash of an infrared laser that focuses on the thin face of the crystal. The pulse lasted only 150 picoseconds and contained a power of 12 trillion watts per square centimeter. The resulting shock wave passed through the diamond crystal, moving at a speed of 72 thousand kilometers per hour.

“To get images of such rapid processes requires the use of a source of extremely short periods of time,” explains Dr. Shropp, “This source was the LCLS X-ray laser, whose pulse has a duration of only 50 femtoseconds, which allows you to capture even the fastest movements. Using X-ray microscopy allowed to obtain a resolution of about 500 nanometers per pixel.

However, each laser "shot" completely destroys the test material sample. So we had to repeat the experiment with identical samples, making one frame of the image at a time. And as a result, we collected from the images a complete video showing the process of the shock wave passing through the diamond crystal.”

Using the obtained video, the scientists were able to determine the quantitative changes in the density of the material during the passage of the shock wave. The analysis showed that the shock wave compresses diamond by about 10 percent, and such deformation can not withstand even the most durable material in the world.

“Due to the fact that diamond has a lot of distinguished physical properties, it is a very useful material both in some research and from a technological point of view,” says Professor Jerome Hastings (Prof. Jerome Hastings) from the SLAC laboratory, “and further study of the properties of this material will significantly expand the areas of its application.”

Scientists expect that the improvement of X-ray lasers and the optimization of the sensors used will allow them in the future to increase the spatial resolution to 100 nanometers per pixel. This will be possible after the commissioning of the new European X-ray laser XFEL, which is currently under construction. Due to the pervasive nature of X-rays, this technology can be used to study any solid material, including metals.

“Such a method of research could yield a great deal of a new field of science called materials science. And, as you know, this science determines a lot that we come into contact with literally every day. It is likely, although it will not be so noticeable, the methods developed by us may have an impact on our lives in the future, concluded Dr. Shropp.

P.S. And remember, just changing our consumption – together we change the world!

Source: www.dailytechinfo.org

Holographic screens on the windshield can be dangerous

James Cameron gave Sunny sunflowers school in Malibu