377

The Japanese created the first rubber-effect transistors

Japanese researchers from the National Institute of AIST (National Institute of Advanced Industrial Science and Technology) has developed a new type of transistors, which are soft, elastic and can withstand a high mechanical stress. Most of the components of these transistors is made of rubber, silicone gel and elastic plastic. Due to this the transistor without loss of health can withstand the mechanical loads, can be immersed in water and they can come female high-heeled stilettos. All this will be made on the basis of such transistors sensors that will be placed on clothing or directly on the floor of residential, office and industrial premises.

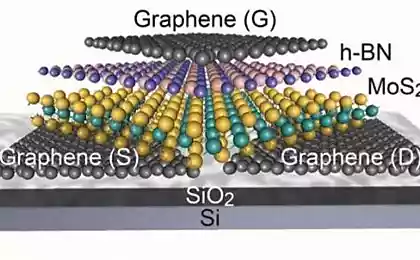

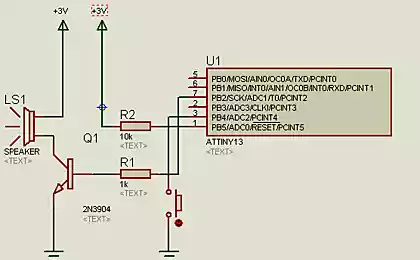

The transistor is produced by forming the gate electrodes, drain, source, a dielectric layer and channel in the volume of silicon-containing rubber, the thickness of which does not exceed 1 millimeter. The size of each transistor is 1 by 1 mm, and the length and width of its channel — 700 and 50 micrometers, respectively.

For the formation of each of the electrodes of the transistor using a composite material whose conductivity has been enhanced by the introduction of carbon nanotubes in the composition of the material. A dielectric layer separating the gate from the channel, made of gel-like polymer material impregnated with the ionic liquid, and the channel represents the path of the carbon nanotubes aligned chaotic manner, so the properties of this track correspond to the properties of a semiconductor material.

The gel-like insulating layer acts not as an oxide layer in a conventional FET. When the gate electric potential is applied, ions begin to move and create additional ion insulating layer which plays the role of the dielectric.

The ratio of the current in the open state to the current in the closed condition the rubber of the transistor is small and is 104 when a gate voltage from -2 to 1 Volt. And these figures do not greatly change in tension of the transistor and then returning it to its original state. Some changes in the parameters have begun to appear only after 1000 strain, when the transistor is stretched to 40-50 percent of its original size. Moreover, the performances of the rubber of the transistor hardly changed when it came to the woman shoes with high stiletto heels. The resulting pressure was 25 kilograms per square centimeter, and is 70 per cent higher than the pressure exerted on the road by a bus Laden vehicle.

"Schemes with a rubber transistors continue to operate even when they are folded or bent at a sharp angle," says Atsuko Sekiguchi (Atsuko Sekiguchi), one of the researchers, "to allow the use of such schemes in even the most challenging environments, on clothing, on walls and floors of the premises, in the industrial equipment on the roads and in many other places where working conditions are far from ideal." published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: vk.com/wiki_inventions?z=photo-56414092_377988965%2Falbum-56414092_00%2Frev

The transistor is produced by forming the gate electrodes, drain, source, a dielectric layer and channel in the volume of silicon-containing rubber, the thickness of which does not exceed 1 millimeter. The size of each transistor is 1 by 1 mm, and the length and width of its channel — 700 and 50 micrometers, respectively.

For the formation of each of the electrodes of the transistor using a composite material whose conductivity has been enhanced by the introduction of carbon nanotubes in the composition of the material. A dielectric layer separating the gate from the channel, made of gel-like polymer material impregnated with the ionic liquid, and the channel represents the path of the carbon nanotubes aligned chaotic manner, so the properties of this track correspond to the properties of a semiconductor material.

The gel-like insulating layer acts not as an oxide layer in a conventional FET. When the gate electric potential is applied, ions begin to move and create additional ion insulating layer which plays the role of the dielectric.

The ratio of the current in the open state to the current in the closed condition the rubber of the transistor is small and is 104 when a gate voltage from -2 to 1 Volt. And these figures do not greatly change in tension of the transistor and then returning it to its original state. Some changes in the parameters have begun to appear only after 1000 strain, when the transistor is stretched to 40-50 percent of its original size. Moreover, the performances of the rubber of the transistor hardly changed when it came to the woman shoes with high stiletto heels. The resulting pressure was 25 kilograms per square centimeter, and is 70 per cent higher than the pressure exerted on the road by a bus Laden vehicle.

"Schemes with a rubber transistors continue to operate even when they are folded or bent at a sharp angle," says Atsuko Sekiguchi (Atsuko Sekiguchi), one of the researchers, "to allow the use of such schemes in even the most challenging environments, on clothing, on walls and floors of the premises, in the industrial equipment on the roads and in many other places where working conditions are far from ideal." published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: vk.com/wiki_inventions?z=photo-56414092_377988965%2Falbum-56414092_00%2Frev