470

New solar panels turn heat into light

A team of researchers from the Massachusetts Institute of technology first demonstrated the device on the basis of a method that allows solar panelproducts predicted using a theoretical ceiling on how much sunlight they can convert into electricity.

The results are presented in the journal Nature Energy, in the work of the doctoral candidate of the Institute David Birman (David Bierman), Professor Evelyn Wang (Evelyn Wang), Soljacic Marin (Marin Soljačić), and four scientists.

While all studies traditional solar cells face the same basic theoretical restrictions, Birman says, "solar thermophotovoltaic elements you have the ability to overcome them."

In fact, the theory predicts that in principle this method, which involves the pairing of conventional solar cells with additional layers of high-tech materials could, at least, to double the theoretical limit of efficiency, potentially making it possible to get two times more power from the same area of panels.

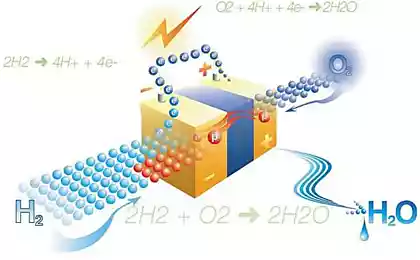

The basic principle is simple: instead of dissipating the solar energy as heat in the solar cell, the entire light and heat first absorbed by the intermediate component, heating it to the temperature, which would allow the component to emit thermal radiation. Tuning the materials and configuration of these added layers, you can control the heat in the form of light with the necessary wavelengths, which will be captured in the solar panels. This increases the efficiency and reduces the heat generated in a solar cell.

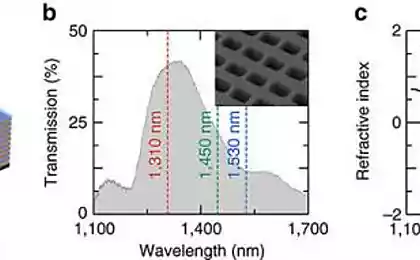

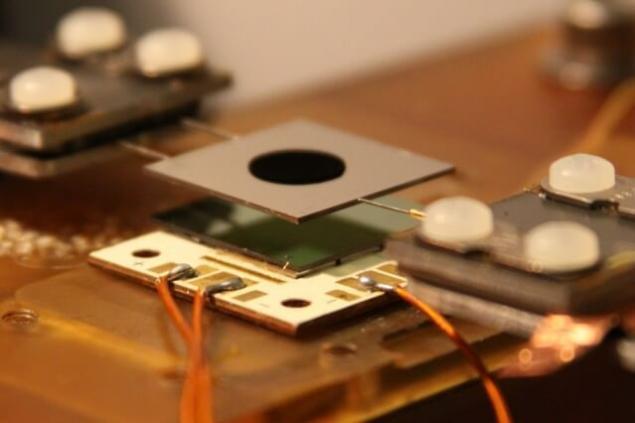

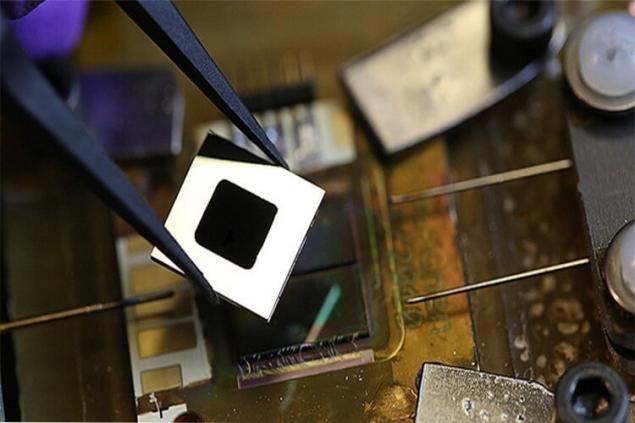

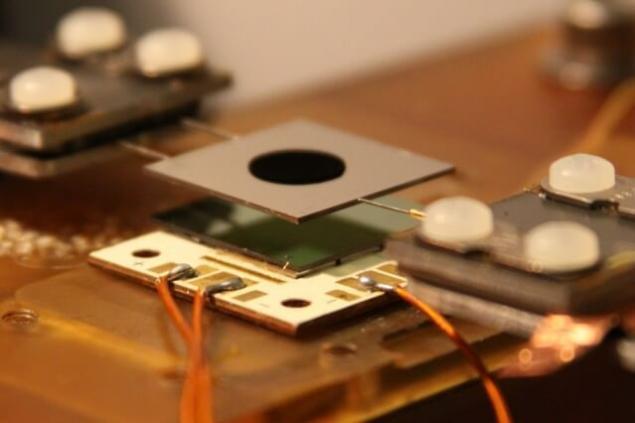

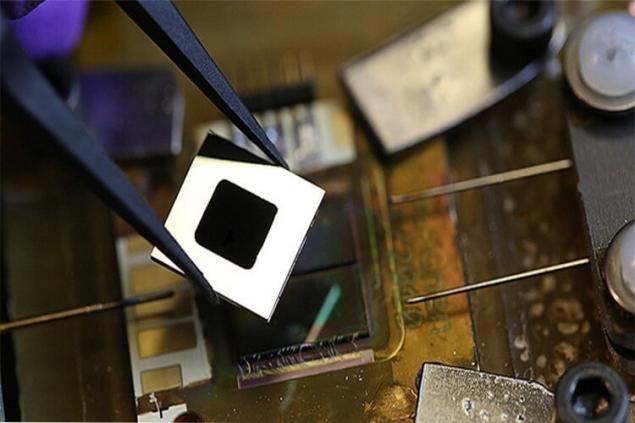

The key point is to use high-tech materials called nanophotonic crystals that can be made to emit specific wavelengths of light when heated. Produced test nanofotonika crystals United in a system with vertically oriented carbon nanotubes, and work under high temperature of 1000 degrees Celsius. After heating nanophotonic crystals continue to emit light with a narrow band spectrum of a specific wavelength, which corresponds exactly to the range that a solar cell can capture and convert into electrical current.

"Carbon nanotubes are almost perfect absorber at the tonal range," says beerman, "that allows him to cover the entire solar spectrum. All the energy of photons is converted into heat". Then, the heat is reradiated in the form of light, but thanks nanophotonic structure, is converted to only the colors that correspond to the maximum efficiency of the photovoltaic cell.

In the process, this approach will use conventional solar-concentrating system with lenses or mirrors focusing the sun's light to maintain a high temperature. An additional component, an improved optical filter passes all of the desired wavelengths of light in the photovoltaic cell, reflecting back any unwanted wavelengths, as even this improved material is not perfect in terms of limiting radiation. The reflected waves then are re-captured, helping to maintain a high temperature photonic crystal.

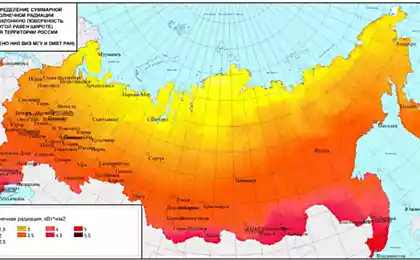

Birman says that such a system can offer a number of advantages compared to conventional photovoltaic panels, whether based on silicon or other materials. On the one hand, the fact that the photonic device produces emissions based on heat, not light means that it will not be affected by brief changes in the environment, such as clouds covering the sun. In fact, combining with the heat storage system, it is, in principle, can ensure the use of solar energy around the clock. "For me, the biggest advantage is the ability to get continuous power on demand," he says.

In addition, due to the way in which the system uses energy that otherwise be wasted as heat, it can reduce excessive heat that can cause damage to some elements of the solar concentrating system.

The next step involves finding ways to make a large version of a small prototype of the experimental setup of laboratory scale and developed methods of fabrication of such systems on a cost effective basis.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: facepla.net/the-news/energy-news-mnu/5476-%D1%81%D0%BE%D0%BB%D0%BD%D0%B5%D1%87%D0%BD%D1%8B%D0%B9-%D1%81%D0%B2%D0%B5%D1%82-%D1%8D%D0%BD%D0%B5%D1%80%D0%B3%D0%B8%D1%8F.html

The results are presented in the journal Nature Energy, in the work of the doctoral candidate of the Institute David Birman (David Bierman), Professor Evelyn Wang (Evelyn Wang), Soljacic Marin (Marin Soljačić), and four scientists.

While all studies traditional solar cells face the same basic theoretical restrictions, Birman says, "solar thermophotovoltaic elements you have the ability to overcome them."

In fact, the theory predicts that in principle this method, which involves the pairing of conventional solar cells with additional layers of high-tech materials could, at least, to double the theoretical limit of efficiency, potentially making it possible to get two times more power from the same area of panels.

The basic principle is simple: instead of dissipating the solar energy as heat in the solar cell, the entire light and heat first absorbed by the intermediate component, heating it to the temperature, which would allow the component to emit thermal radiation. Tuning the materials and configuration of these added layers, you can control the heat in the form of light with the necessary wavelengths, which will be captured in the solar panels. This increases the efficiency and reduces the heat generated in a solar cell.

The key point is to use high-tech materials called nanophotonic crystals that can be made to emit specific wavelengths of light when heated. Produced test nanofotonika crystals United in a system with vertically oriented carbon nanotubes, and work under high temperature of 1000 degrees Celsius. After heating nanophotonic crystals continue to emit light with a narrow band spectrum of a specific wavelength, which corresponds exactly to the range that a solar cell can capture and convert into electrical current.

"Carbon nanotubes are almost perfect absorber at the tonal range," says beerman, "that allows him to cover the entire solar spectrum. All the energy of photons is converted into heat". Then, the heat is reradiated in the form of light, but thanks nanophotonic structure, is converted to only the colors that correspond to the maximum efficiency of the photovoltaic cell.

In the process, this approach will use conventional solar-concentrating system with lenses or mirrors focusing the sun's light to maintain a high temperature. An additional component, an improved optical filter passes all of the desired wavelengths of light in the photovoltaic cell, reflecting back any unwanted wavelengths, as even this improved material is not perfect in terms of limiting radiation. The reflected waves then are re-captured, helping to maintain a high temperature photonic crystal.

Birman says that such a system can offer a number of advantages compared to conventional photovoltaic panels, whether based on silicon or other materials. On the one hand, the fact that the photonic device produces emissions based on heat, not light means that it will not be affected by brief changes in the environment, such as clouds covering the sun. In fact, combining with the heat storage system, it is, in principle, can ensure the use of solar energy around the clock. "For me, the biggest advantage is the ability to get continuous power on demand," he says.

In addition, due to the way in which the system uses energy that otherwise be wasted as heat, it can reduce excessive heat that can cause damage to some elements of the solar concentrating system.

The next step involves finding ways to make a large version of a small prototype of the experimental setup of laboratory scale and developed methods of fabrication of such systems on a cost effective basis.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: facepla.net/the-news/energy-news-mnu/5476-%D1%81%D0%BE%D0%BB%D0%BD%D0%B5%D1%87%D0%BD%D1%8B%D0%B9-%D1%81%D0%B2%D0%B5%D1%82-%D1%8D%D0%BD%D0%B5%D1%80%D0%B3%D0%B8%D1%8F.html