409

European researchers have created a new composite material with variable transparency

Materials with variable transparency are not new, but a group of German and Danish scientists have made considerable progress in this matter. In their paper, the researchers describe the polymer-dispersed material based on liquid crystals (PDLC), which is faster and more other such development changes its transparency from fully transparent "plastic", to "deaf" white. Transparent material is 8 milliseconds (to human eyes — instantly), and opaque — in 80 milliseconds. Officially, the novelty will be presented in October as part of the technology Symposium UIST 2016, which will be held from 16 to 19 October in Tokyo, Japan.

To participate in UIST 2016 the group has prepared a special video presentation now available on Youtube:

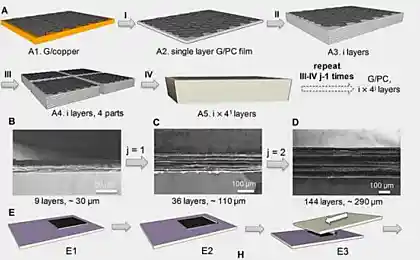

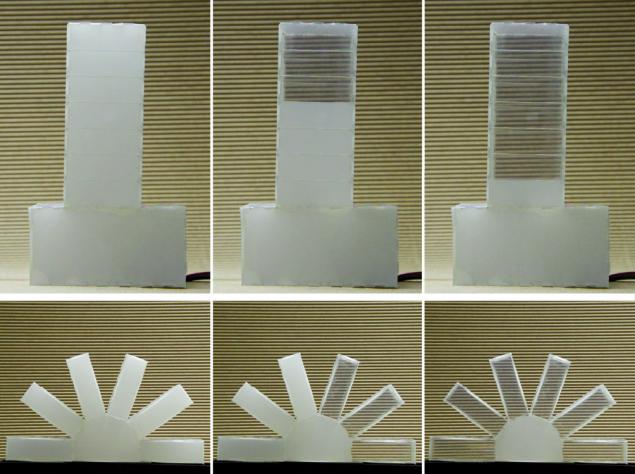

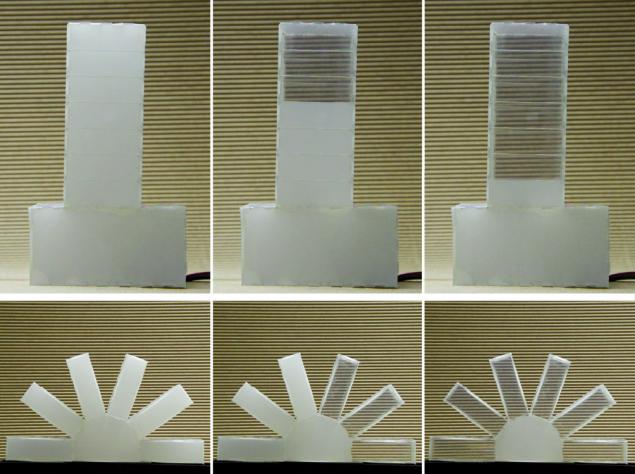

Models created by using new material, highly reminiscent of the inextricable origami, which classically are made of a single sheet of paper. On bends "sheet" researchers are setting up special contacts that allow you to distinguish and control the individual segments. The transparency of the material also changes under the influence of an electric voltage of 60 V. To maintain the transparent state requires about 10 mA per m2 of the material in the opaque state, the current is not required.

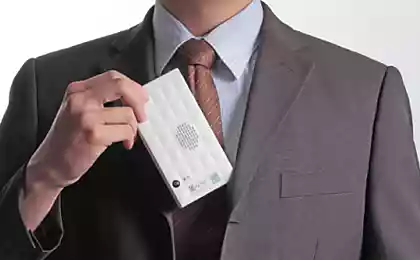

Use of the material for the manufacture of physical indicators, such as the free space on the hard disk

In their work the researchers note that the transparency of the material when current is applied changes almost linearly, i.e. its properties will change with the flow 20 In, however, claimed up to 90% of light transmission during normal voltage of 60 V will be as far as when submitting, for example, 40 V.

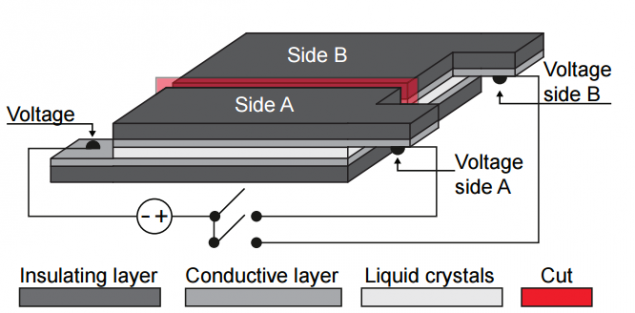

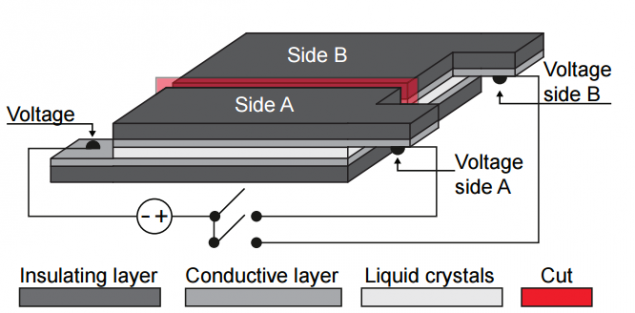

The material itself is made of several layers. On the external side is the insulating layer, followed by a layer of transparent conductive film is fabricated using indium-tin oxide. Between the conductive layers is placed a layer of liquid crystals:

Also the technology of creating and managing products PDLC allows you to get rid of one of the main problems in the design of such things — posting. Marking tracks is produced directly in the material. The only wires that will be present in such objects — the connection to the current source. Design of sheet billet is produced in special, on the model of which the laser burns required "origami"-processing.

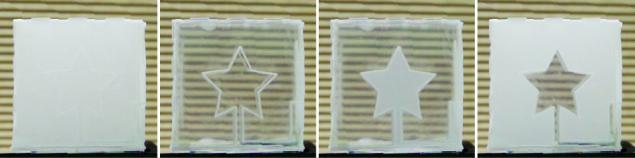

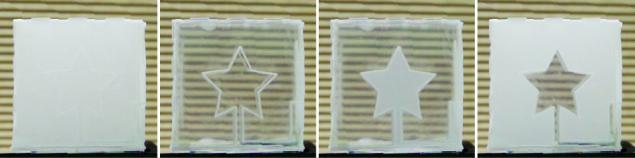

An example of a marking region, the transparency of which is controlled separately from the main unit

The main application of innovations, its creators see the physical interfaces that are now used led and LED technology, as well as in the production of interactive panels and transparent monitors. One of the benefits of development is called what from a sheet of this material it is possible to gather a complete three-dimensional object with variable transparency, and can control not only the product as a whole, but its component parts and even individual region in the framework of the "plate."

Source: geektimes.ru/post/280348/

To participate in UIST 2016 the group has prepared a special video presentation now available on Youtube:

Models created by using new material, highly reminiscent of the inextricable origami, which classically are made of a single sheet of paper. On bends "sheet" researchers are setting up special contacts that allow you to distinguish and control the individual segments. The transparency of the material also changes under the influence of an electric voltage of 60 V. To maintain the transparent state requires about 10 mA per m2 of the material in the opaque state, the current is not required.

Use of the material for the manufacture of physical indicators, such as the free space on the hard disk

In their work the researchers note that the transparency of the material when current is applied changes almost linearly, i.e. its properties will change with the flow 20 In, however, claimed up to 90% of light transmission during normal voltage of 60 V will be as far as when submitting, for example, 40 V.

The material itself is made of several layers. On the external side is the insulating layer, followed by a layer of transparent conductive film is fabricated using indium-tin oxide. Between the conductive layers is placed a layer of liquid crystals:

Also the technology of creating and managing products PDLC allows you to get rid of one of the main problems in the design of such things — posting. Marking tracks is produced directly in the material. The only wires that will be present in such objects — the connection to the current source. Design of sheet billet is produced in special, on the model of which the laser burns required "origami"-processing.

An example of a marking region, the transparency of which is controlled separately from the main unit

The main application of innovations, its creators see the physical interfaces that are now used led and LED technology, as well as in the production of interactive panels and transparent monitors. One of the benefits of development is called what from a sheet of this material it is possible to gather a complete three-dimensional object with variable transparency, and can control not only the product as a whole, but its component parts and even individual region in the framework of the "plate."

Source: geektimes.ru/post/280348/

Proven the authenticity of the Code of the Continent — the fourth of the surviving Maya Codex

Happy birthday, Stanislaw LEM