488

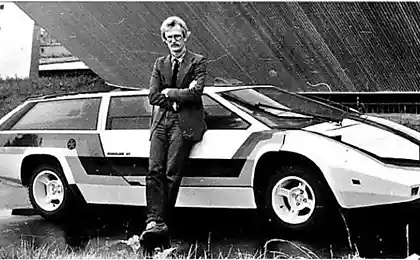

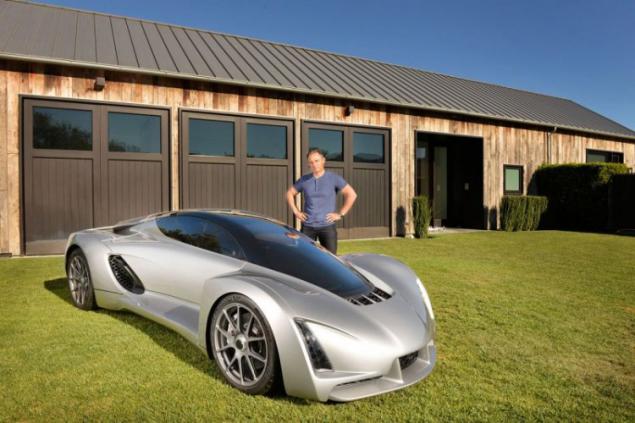

The 3D-printer manufactured body supercar

Divergent Microfactories American company in San Francisco designed a car Blade («Blade"), a body which is made with help of 3D-printing.

Name supercar - Blade. It weighs 629 kg and is dispersed to first hundred for 2, 5 seconds. Its 700-horsepower engine runs on gasoline or compressed gas.

This is because of the production process virtually eliminate stage factory. "Lego" printed from the 3D-printer module aluminum and carbon tubes supplied to the Collector number not more than three persons and those collected from a chassis. Of course, not in the shop.

27, 6 and 18 kg of aluminum, 6 kg of carbon - what else is needed for the chassis Blade? Never mind! In manual assembly takes half an hour.

Name supercar - Blade. It weighs 629 kg and is dispersed to first hundred for 2, 5 seconds. Its 700-horsepower engine runs on gasoline or compressed gas.

This is because of the production process virtually eliminate stage factory. "Lego" printed from the 3D-printer module aluminum and carbon tubes supplied to the Collector number not more than three persons and those collected from a chassis. Of course, not in the shop.

27, 6 and 18 kg of aluminum, 6 kg of carbon - what else is needed for the chassis Blade? Never mind! In manual assembly takes half an hour.