921

Using the machine in the industry ADPM

< mobile unit dewaxing upgraded 12/150 is most often used on those deposits in which there is a shortage of water source. Most often, manufacturing ADPM occurs on truck chassis of the vehicle.

Oil is a very complex process, which hides a lot of problems. And only when they are educated decision can achieve good results in the production of high-quality raw materials ready. For one of these problems can be attributed layering wax compounds on the walls of the wells that hinder productivity of the process, making it difficult to process the fuel. However, to address this issue helps unit ADPM , specially made for this purpose.

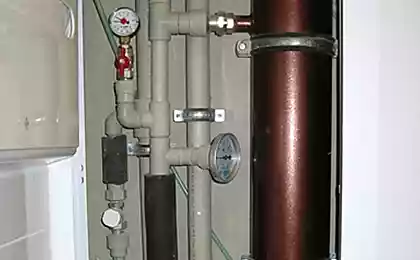

Dewaxing unit mobile modernized 12/150 is most often used on those deposits in which there is a shortage of water source. Most often occurs at ADPM manufacturing goods vehicle chassis. In rare cases, it can be found in the form of a fixed or sleigh rides. To accommodate the equipment, a special playground. The main unit is the unit in a vertical cylindrical heater of the boiler, and the ram-type coil. With this heating process is carried heater oil or liquid industrial water to a high temperature reaching 150 degrees. In the driver's cab is a special panel to the control unit with which the workflow is initiated and the unit. Needle valve for supplying fuel to the heating structure. This process can be carried out not only from the driver's cab but also from the platform itself.

Action mechanisms ADPM going on means of a special box that lets you select the desired output power through the engine chassis. In order to reduce the load on the power device has been provided for the gearbox. To ensure reliable operation, the device is equipped with electrical equipment fire safety system.

Operation ADPM provides for the tanker, which allows pumping black fuel or industrial water pump through a special sleeve, mounted on a platform device, and liquid to pass through the heating boiler. Fuel brought to the desired temperature level, through the main pipelines swinging into the well, which is a process of melting and deposition of paraffin mixture, and the withdrawal of fishing line to the team.

Correct maintenance and timely replacement of spare parts ensures that the unit will operate smoothly ADPM even in the most severe climatic conditions.

Oil is a very complex process, which hides a lot of problems. And only when they are educated decision can achieve good results in the production of high-quality raw materials ready. For one of these problems can be attributed layering wax compounds on the walls of the wells that hinder productivity of the process, making it difficult to process the fuel. However, to address this issue helps unit ADPM , specially made for this purpose.

Dewaxing unit mobile modernized 12/150 is most often used on those deposits in which there is a shortage of water source. Most often occurs at ADPM manufacturing goods vehicle chassis. In rare cases, it can be found in the form of a fixed or sleigh rides. To accommodate the equipment, a special playground. The main unit is the unit in a vertical cylindrical heater of the boiler, and the ram-type coil. With this heating process is carried heater oil or liquid industrial water to a high temperature reaching 150 degrees. In the driver's cab is a special panel to the control unit with which the workflow is initiated and the unit. Needle valve for supplying fuel to the heating structure. This process can be carried out not only from the driver's cab but also from the platform itself.

Action mechanisms ADPM going on means of a special box that lets you select the desired output power through the engine chassis. In order to reduce the load on the power device has been provided for the gearbox. To ensure reliable operation, the device is equipped with electrical equipment fire safety system.

Operation ADPM provides for the tanker, which allows pumping black fuel or industrial water pump through a special sleeve, mounted on a platform device, and liquid to pass through the heating boiler. Fuel brought to the desired temperature level, through the main pipelines swinging into the well, which is a process of melting and deposition of paraffin mixture, and the withdrawal of fishing line to the team.

Correct maintenance and timely replacement of spare parts ensures that the unit will operate smoothly ADPM even in the most severe climatic conditions.