1186

Augean stables of domestic stankoproma

Soviet Carthage was destroyed by the signatures of three slightly tipsy (or rather, only two slightly) is not quite appropriate people. The consequences we are seeing so far and still can not help wondering how we managed it prolyubit such country. Today we visit the workshop of the former machine-tool plants and once again make sure that the 90 were not in time, and weapons of mass destruction, not schadivshim no people, no factories, nothing.

40 photos

Well, welcome to the factory. We start our tour.

Ergonomics thought out to the smallest detail. Place in a confined space, several important objects - it is art. But who is wondering when the room has a terrifying appearance.

The once clean and well maintained bathroom had forgotten what being clean. On the 90th, no one to make an effort to return it to its former white crystal. And he does not mind, among other things.

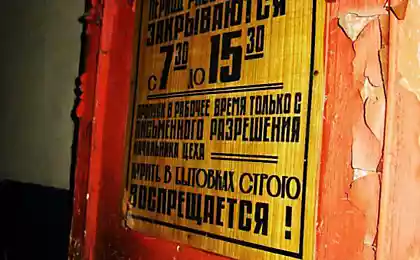

"Honor and glory to his work." Are you serious ?!

On the question of safety always comes up especially serious. However, now 20 years old as unsafe to be here

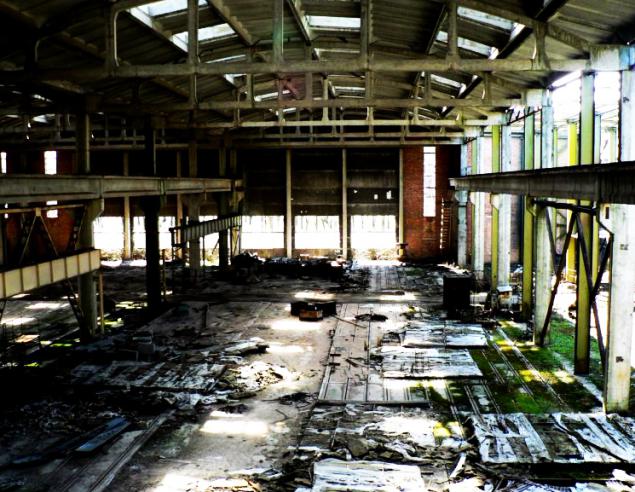

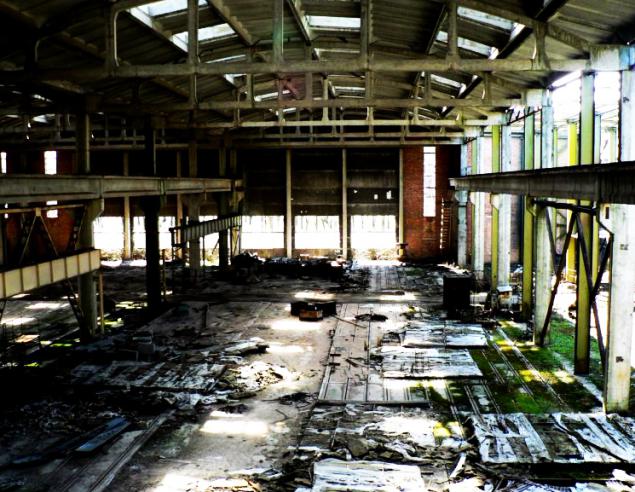

I understand this is a beautiful assembly hall. In the past, of course. How could destroy such capacity - still remains a mystery.

Peter, do you remember?

But once this console could do and feeding, and was able to do other cool stuff.

A good idea to revive life in this rotten for years indoors

Gentleman set chief of the Yeltsin era - calendar, matches, kettle and disk phone. To complete the picture is not enough just to slap release, here it delicately replaced the stale skanvordov.

From the former working atmosphere here was only a stubby hood. But the photo Nitsche so simpatichnenkaya.

Time would have to burn everything here and restore production capacity. So just like in Soviet times were - when you look at them, then everyone stands around and smoke from ecstasy, for fascinating spectacle.

Even imagine what could be here before.

Pay Attention to Daniel's Prophecy - he is a man thing!

No, well able to agree to implement the same in such seemingly harsh factory building as a piece of beauty. As can be seen, in spite of all the hardships of the structure in the post-Soviet period to part with the lovely it is not ready.

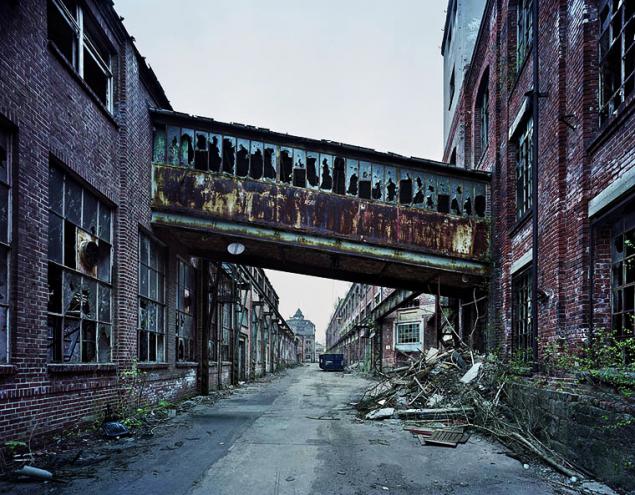

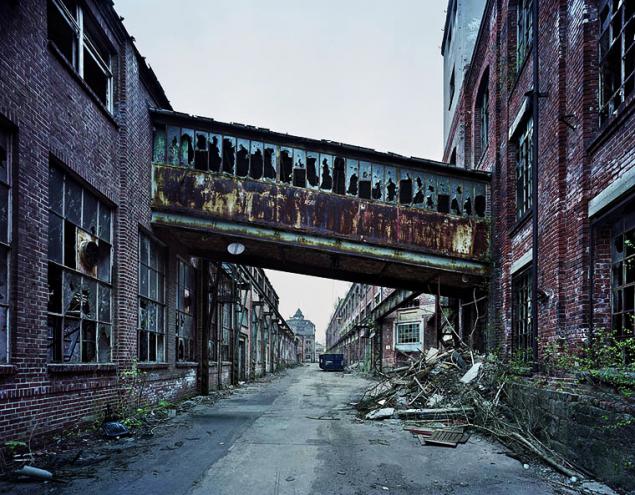

Go through this transition is not something that you want, and just even dangerous. He and look to break apart.

NaSTOLzhi, as they say. Perhaps this device was in the office of a textured superior, of those that love to dress up in a crimson jacket.

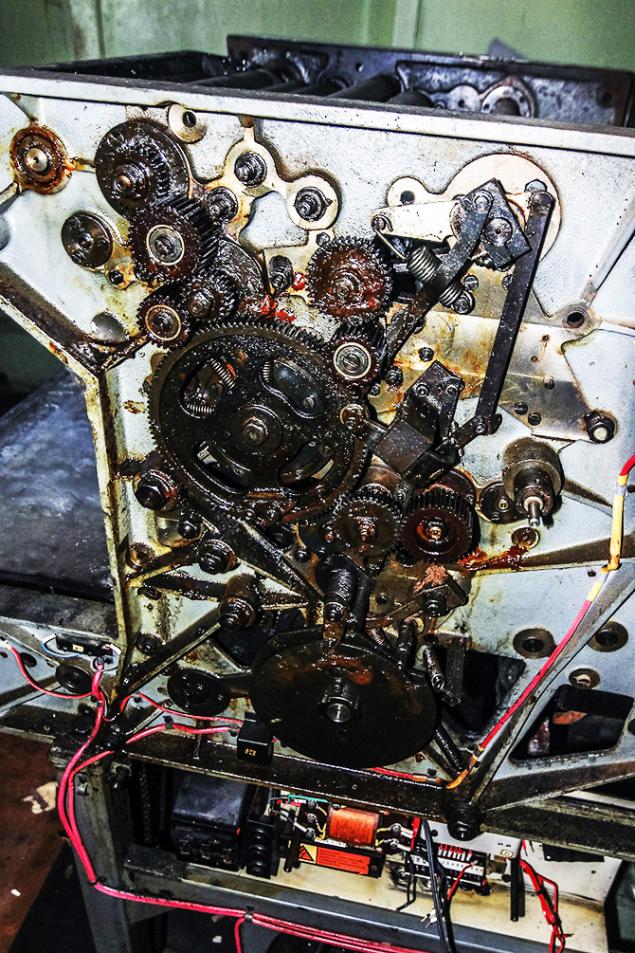

All these machines can be restored if desired and restart the work. But that's why it was to bring the units to the point - the question.

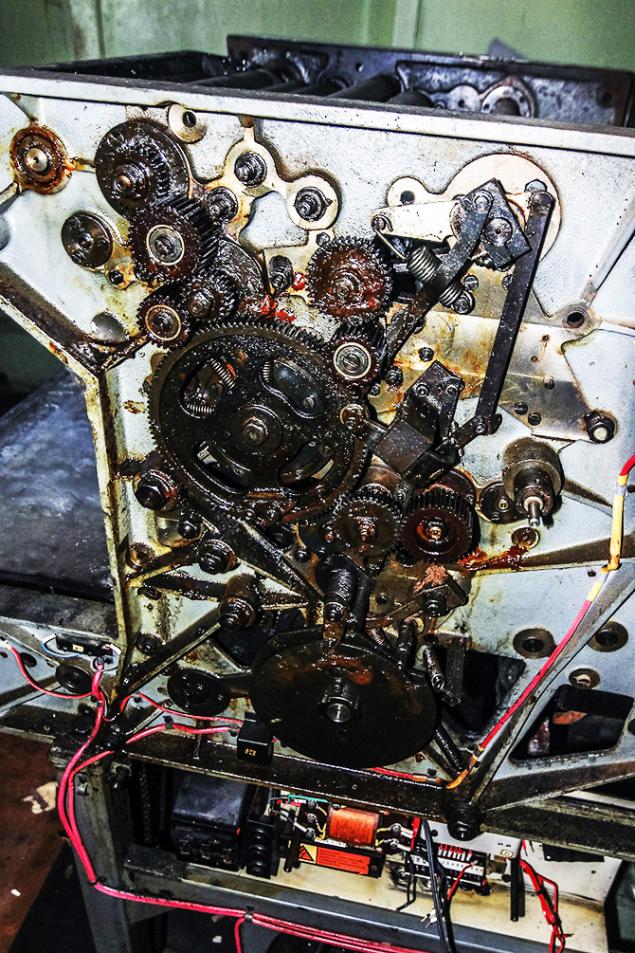

All hopelessness stankoproma 90s in one photo.

19

This building is dangerous to life, not only your hands to the plate, here even be dumb.

Why such a hole in the ceiling? For the vast Santa Claus? We have Santa Claus actually knocking on the door.

"Study, study and study again" - clearly not about the guys who work here. At that time it seemed that simply stupid hack loot.

But the caretaker should be commended. Years later, nothing is lost, everything is also compact.

From the "No comment." Brought the building.

The only thing that reminds of former workflow.

Generally, the sad situation today in the domestic stankoprome looms. The share of the USSR of the world production of machine tools according to 1954 was 18%. Russia now has a share of 0, 3%.

In the late eighties the Soviet Union came in third place in the production of machine tool world powers. Japan held the first place, the second - Germany, the fourth - the United States. Back in 1990 the Soviet Union occupied the third place in the world in the production and consumption of the second machining equipment. Today, Russia is on these indicators, respectively on 22 th and 17 th places.

From 1984 to 1990, only Germany has been exported more than 45 thousand. Machines. The peak of our success was, perhaps, in 1990, when at the international exhibition in Paris exposed us all 49 machines were there and bought.

In 1986, the Soviet Union produced 220 thousand machines a year. In 1991, production dropped to 76 thousand. In 2012, Russia produced only 3000 machines. At that annual demand of industry - not less than 50 million units of the new machining equipment.

Park Soviet metalworking equipment by 94% of the country was ote¬chestvennym. Today, the share of domestic machine is no more than 10%. In Russia imported three times more equipment than is produced domestically. 80% of imports - China and Thailand, 5-7% - Europe. But a few decades ago, China did not have the machine tool.

At the moment, moral and physical depreciation of fixed assets, primarily metalworking equipment in the Russian engineering has reached 70-80%. Every year, the country loses more than 50 thousand. Machines.

Currently preserved about 180 machine tool companies and organizations, representing approximately 70% of the ex-Soviet industrial might. The volume of manufactured products remaining capacity is 5% of the USSR. Already completely destroyed 42 machine tool company.

Share of the machine tool in the volume of industrial production in Russia is 19, 5%. For comparison, this figure in Germany, Japan, USA and others. Developed countries is 39 to 45%.

The volume of production of metalworking equipment in Russia in 2011 amounted to about 164 million dollars. The contribution of the machine tool in Russia's GDP in 2011 - 0 023%. According to these indicators, Russia lags far behind leading countries. In particular, in the same year, China produced 27 metalworking equipment, $ 7 billion. (Machine tool industry contribution to GDP - 0, 78%), Japan - 18, 4 billion (0, 73%), Germany - 13, 5 billion (0, 71%), Italy - 6, $ 2 billion. (0, 39%).

Negative trends in the development of the domestic machine tool industry has not saved the first decade.

If the industry will not change anything, everything loud statements about modernization can be considered idle chatter. Having your own machine tools - this is the first condition for the industrial independence of the country and as a consequence of its political and economic independence.

Workshops are empty, no one to work.

Key stroke, which once regularly Run advanced trudoprotsess.

At the moment the machines on abandoned Machine Tool Works actively pulled apart for scrap. Given that the capacity of machines after repair would be enough for a few more years.

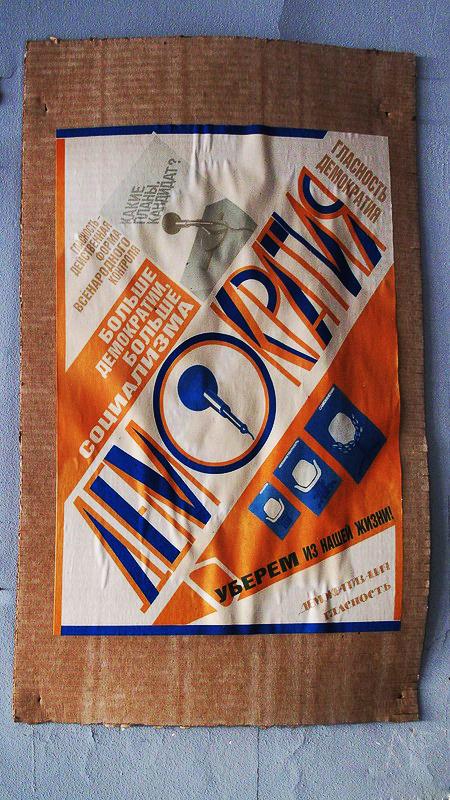

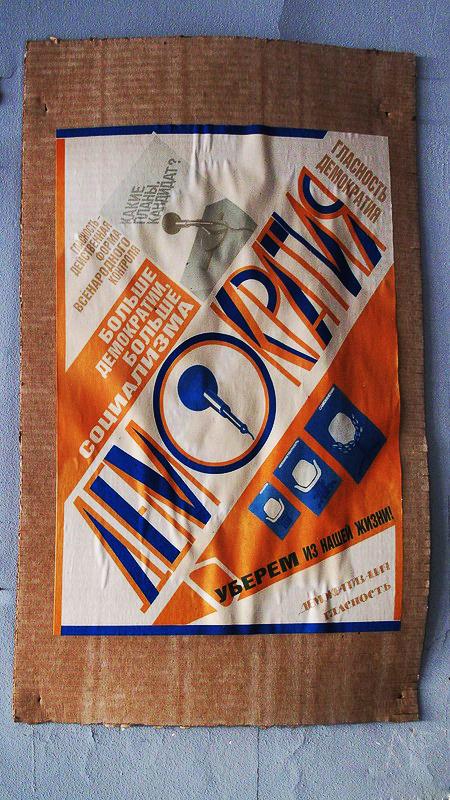

Lunch break. Forever. It is unfortunate that this industry in our country started. Of course, now first attempts to resuscitate Stankoprom. But the situation is more reminiscent of the story of the Augean stables. Accumulated so much crap that have to wash a very long time. Some enterprises gradually rise from the ruins, but the overall situation is dire. To raise our Stankoprom insufficient purchases of German and Chinese glazing machines, need a global and serious work. In the meantime, what we have - and what we have. Collapsed machines plundered shops and faded posters - that's us and the memories of the once powerful industry.

All

40 photos

Well, welcome to the factory. We start our tour.

Ergonomics thought out to the smallest detail. Place in a confined space, several important objects - it is art. But who is wondering when the room has a terrifying appearance.

The once clean and well maintained bathroom had forgotten what being clean. On the 90th, no one to make an effort to return it to its former white crystal. And he does not mind, among other things.

"Honor and glory to his work." Are you serious ?!

On the question of safety always comes up especially serious. However, now 20 years old as unsafe to be here

I understand this is a beautiful assembly hall. In the past, of course. How could destroy such capacity - still remains a mystery.

Peter, do you remember?

But once this console could do and feeding, and was able to do other cool stuff.

A good idea to revive life in this rotten for years indoors

Gentleman set chief of the Yeltsin era - calendar, matches, kettle and disk phone. To complete the picture is not enough just to slap release, here it delicately replaced the stale skanvordov.

From the former working atmosphere here was only a stubby hood. But the photo Nitsche so simpatichnenkaya.

Time would have to burn everything here and restore production capacity. So just like in Soviet times were - when you look at them, then everyone stands around and smoke from ecstasy, for fascinating spectacle.

Even imagine what could be here before.

Pay Attention to Daniel's Prophecy - he is a man thing!

No, well able to agree to implement the same in such seemingly harsh factory building as a piece of beauty. As can be seen, in spite of all the hardships of the structure in the post-Soviet period to part with the lovely it is not ready.

Go through this transition is not something that you want, and just even dangerous. He and look to break apart.

NaSTOLzhi, as they say. Perhaps this device was in the office of a textured superior, of those that love to dress up in a crimson jacket.

All these machines can be restored if desired and restart the work. But that's why it was to bring the units to the point - the question.

All hopelessness stankoproma 90s in one photo.

19

This building is dangerous to life, not only your hands to the plate, here even be dumb.

Why such a hole in the ceiling? For the vast Santa Claus? We have Santa Claus actually knocking on the door.

"Study, study and study again" - clearly not about the guys who work here. At that time it seemed that simply stupid hack loot.

But the caretaker should be commended. Years later, nothing is lost, everything is also compact.

From the "No comment." Brought the building.

The only thing that reminds of former workflow.

Generally, the sad situation today in the domestic stankoprome looms. The share of the USSR of the world production of machine tools according to 1954 was 18%. Russia now has a share of 0, 3%.

In the late eighties the Soviet Union came in third place in the production of machine tool world powers. Japan held the first place, the second - Germany, the fourth - the United States. Back in 1990 the Soviet Union occupied the third place in the world in the production and consumption of the second machining equipment. Today, Russia is on these indicators, respectively on 22 th and 17 th places.

From 1984 to 1990, only Germany has been exported more than 45 thousand. Machines. The peak of our success was, perhaps, in 1990, when at the international exhibition in Paris exposed us all 49 machines were there and bought.

In 1986, the Soviet Union produced 220 thousand machines a year. In 1991, production dropped to 76 thousand. In 2012, Russia produced only 3000 machines. At that annual demand of industry - not less than 50 million units of the new machining equipment.

Park Soviet metalworking equipment by 94% of the country was ote¬chestvennym. Today, the share of domestic machine is no more than 10%. In Russia imported three times more equipment than is produced domestically. 80% of imports - China and Thailand, 5-7% - Europe. But a few decades ago, China did not have the machine tool.

At the moment, moral and physical depreciation of fixed assets, primarily metalworking equipment in the Russian engineering has reached 70-80%. Every year, the country loses more than 50 thousand. Machines.

Currently preserved about 180 machine tool companies and organizations, representing approximately 70% of the ex-Soviet industrial might. The volume of manufactured products remaining capacity is 5% of the USSR. Already completely destroyed 42 machine tool company.

Share of the machine tool in the volume of industrial production in Russia is 19, 5%. For comparison, this figure in Germany, Japan, USA and others. Developed countries is 39 to 45%.

The volume of production of metalworking equipment in Russia in 2011 amounted to about 164 million dollars. The contribution of the machine tool in Russia's GDP in 2011 - 0 023%. According to these indicators, Russia lags far behind leading countries. In particular, in the same year, China produced 27 metalworking equipment, $ 7 billion. (Machine tool industry contribution to GDP - 0, 78%), Japan - 18, 4 billion (0, 73%), Germany - 13, 5 billion (0, 71%), Italy - 6, $ 2 billion. (0, 39%).

Negative trends in the development of the domestic machine tool industry has not saved the first decade.

If the industry will not change anything, everything loud statements about modernization can be considered idle chatter. Having your own machine tools - this is the first condition for the industrial independence of the country and as a consequence of its political and economic independence.

Workshops are empty, no one to work.

Key stroke, which once regularly Run advanced trudoprotsess.

At the moment the machines on abandoned Machine Tool Works actively pulled apart for scrap. Given that the capacity of machines after repair would be enough for a few more years.

Lunch break. Forever. It is unfortunate that this industry in our country started. Of course, now first attempts to resuscitate Stankoprom. But the situation is more reminiscent of the story of the Augean stables. Accumulated so much crap that have to wash a very long time. Some enterprises gradually rise from the ruins, but the overall situation is dire. To raise our Stankoprom insufficient purchases of German and Chinese glazing machines, need a global and serious work. In the meantime, what we have - and what we have. Collapsed machines plundered shops and faded posters - that's us and the memories of the once powerful industry.

All