660

How do diamonds.

In this post I'll show you how clearly of a piece of stone make the eternal beauty.

13 photo + letter.

1.

2. To start you need to get a diamond, this field is developed, in this case the kimberlite pipe.

3. Diamonds come in all colors and shades, but the basic white, yellow, brownish gray. Geometric shapes octahedron cube and rhombic dodecahedron. The photo of washed and ready for sorting raw materials.

4. Then there is a sort of raw material to determine the future of stones, technical raw material or Gemmological.

5. Following the selection of raw materials is Gemmological metering and marking followed by sawing and cut.

6. When a stone is marked and has already decided what and how much will go diamond sawing.

7. Top mechanical way of cutting (about a week to cut out the middle stone).

Here, an alternative method - laser cutting (approximately an average day sawn stone, but the loss of more raw materials in the process).

8. Laser cutting close.

9. Then there is peeling, half octahedra rub each other, which would take the form of a cone and the diameter of the outline of the future of the diamond.

10. The stone needs to be fixed in the holder, which holds it in the cut.

11. diamond cutting machine.

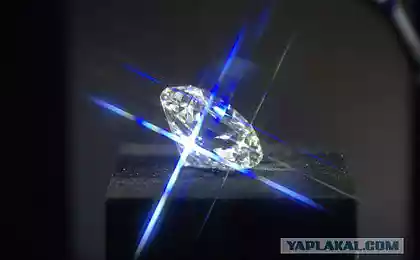

12. Outcome:

13. Compare the beginning of the path to conversion into diamond diamonds:

Source:

13 photo + letter.

1.

2. To start you need to get a diamond, this field is developed, in this case the kimberlite pipe.

3. Diamonds come in all colors and shades, but the basic white, yellow, brownish gray. Geometric shapes octahedron cube and rhombic dodecahedron. The photo of washed and ready for sorting raw materials.

4. Then there is a sort of raw material to determine the future of stones, technical raw material or Gemmological.

5. Following the selection of raw materials is Gemmological metering and marking followed by sawing and cut.

6. When a stone is marked and has already decided what and how much will go diamond sawing.

7. Top mechanical way of cutting (about a week to cut out the middle stone).

Here, an alternative method - laser cutting (approximately an average day sawn stone, but the loss of more raw materials in the process).

8. Laser cutting close.

9. Then there is peeling, half octahedra rub each other, which would take the form of a cone and the diameter of the outline of the future of the diamond.

10. The stone needs to be fixed in the holder, which holds it in the cut.

11. diamond cutting machine.

12. Outcome:

13. Compare the beginning of the path to conversion into diamond diamonds:

Source: