789

What's going on, "Mikhailovsky Broiler"

Writes lena-ryzhaya:

On the Friday went to a part of the tour with journalists and activists of forum "Vladmama" to "Michalowski broiler" (abbreviated as MB).

Photos in such places rarely allowed, so this opportunity could not be missed.

The whole event was timed to an active campaign to promote the new products MB - chicken sausages (sausages, salami, smoked chicken legs, and others.)

The total area of MB - 170Ga on the territory of 59 houses for chickens. Chickens grown about 2 million broilers. Broilers, it is chicken, which do not reach sexual maturity and are intended only for meat.

This building incubator MB. A low, never understand what was going on inside.

In this form we were at the factory: gowns, caps, gloves, shoe covers and masks.

This incubator itself, the first thing we were led here, to show how the report begins production. Hatching eggs produced on "Nadezhdinskaya poultry farm" and brought here.

Since bookmarks eggs in an incubator until the chicken is held 21 days after they are populated into the house, where they spend 42 days prior to slaughter. Incubator temperature was 37, 6.

Another incubator since vyluplivivshimsya chickens. After the appearance of chicken incubator employees inspect each one, then vaccinate and send chickens in poultry houses.

Sorting and cleaning chickens from the shell. At the same time there is a check on its viability, it is placed on the back to see if he can stand on their own, and if he had inhaled the navel. The factory employs many immigrants from Central Asia, however, according to the director, the problem of alcoholism in the production they are not worried.

This chick has not passed the test of aptitude.

Warm chicken brotherhood.

OTV-Schnick was not easy, we quickly moved from one sector to another.

Before sending in the farm, the chickens are placed in the basket. The Director-General IB, Gregory Patrushev, vladmamam shows and tells how and what was going on.

Chicken feels incredibly nice and warm. His fate did not want to think.

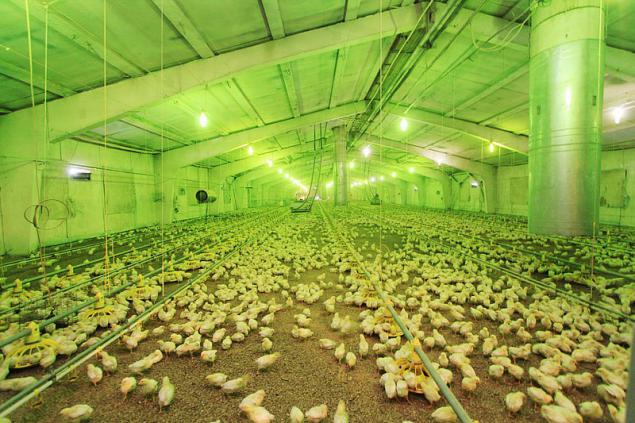

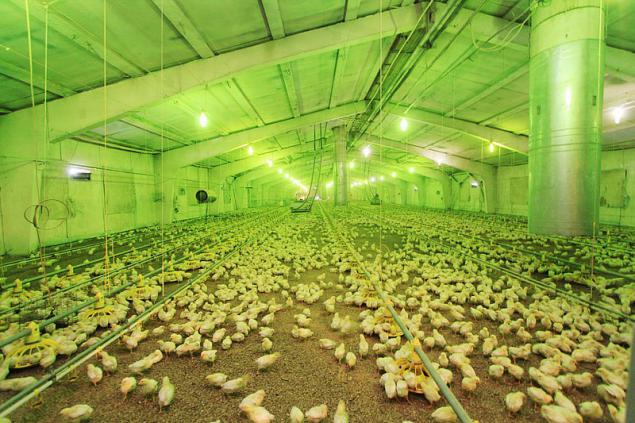

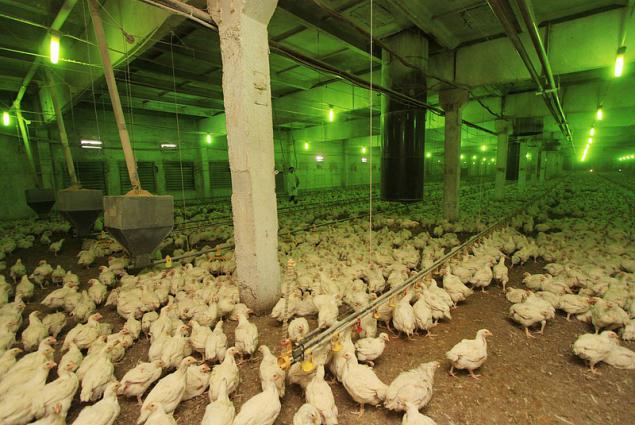

In this light, a la "The Matrix" chickens were fed and they grow-grow-grow. It turned out that the green light is ideal for the development of bird.

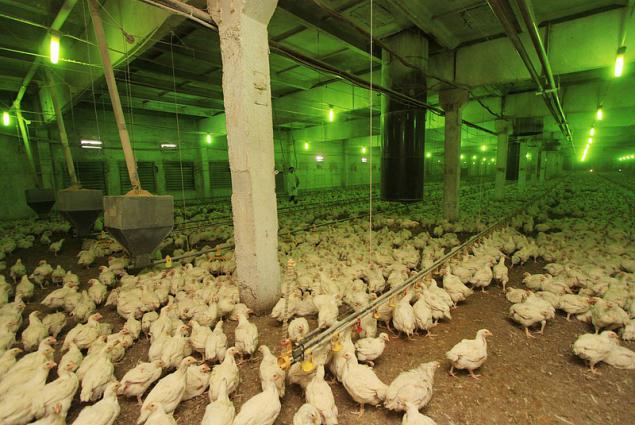

The factory is used as the floor and the cell system of poultry. Before us is a cell.

Chickens fed forage from different grains (wheat, corn, soybeans), concentrate feed (soy, sunflower), there are minerals, protein materials, vegetable oil. At MB own feed mill.

This house with a floor system of poultry. Feeling psychedelic not leave.

Here it is, our northern eagle!

Older birds are in a different house. Unlike active chickens, they are moved by a measured area.

Director of the factory Grigory Patrushev is surrounded by member "Vladmama" and journalists on the background of the feed mill MB.

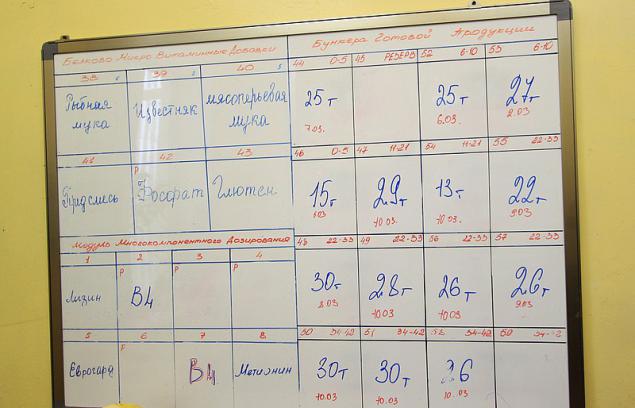

Inside the feed mill. In the day to feed the chick takes about 2, 5 wagons feed (110-130 tons). The plant - the pride of MB, in addition to its own stores of grain and railway siding, by which the delivery of raw materials for animal feed.

The process of mixing of feed is controlled by the operator using the computer system of the plant, with mathematical precision.

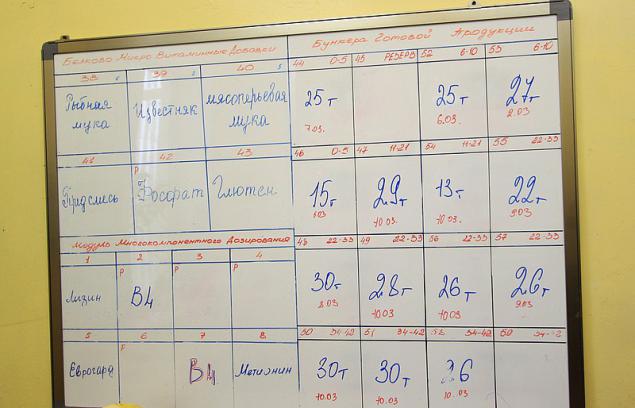

The plant produces 5 types of feed for your chickens every age. On the left side marker blackboard written vitamin supplements.

Before you get into the industrial complex, you need to be cleaned with brushes.

Upon reaching 42 days of age, chickens delivered from the poultry houses in the complex poultry processing, where the number of processing steps. Before slaughter of birds stunned shock. Then comes the removal of plumage and gutting.

This picture may be left without comment.

Fully refined bird enters the chamber droplet cooling. To carcasses not zavetrivalis not blush, here are constantly sprayed moisture. Powered photographer VL.RU.

After cooling, the chicks are sorted with the mandatory health kontrolem.Otobrannye broilers are sent to the shop cutting and packaging.

The production complex, even as the people working arrangements, practice and experience of doing their job.

Another phase of cutting.

Packing and packaging whole carcases before being sent to the storage chamber.

They make sausages "Egerskie."

Workshop packing products MB.

Finished products "Mikhailovsky Broiler".

via lena-ryzhaya LJ

Source:

On the Friday went to a part of the tour with journalists and activists of forum "Vladmama" to "Michalowski broiler" (abbreviated as MB).

Photos in such places rarely allowed, so this opportunity could not be missed.

The whole event was timed to an active campaign to promote the new products MB - chicken sausages (sausages, salami, smoked chicken legs, and others.)

The total area of MB - 170Ga on the territory of 59 houses for chickens. Chickens grown about 2 million broilers. Broilers, it is chicken, which do not reach sexual maturity and are intended only for meat.

This building incubator MB. A low, never understand what was going on inside.

In this form we were at the factory: gowns, caps, gloves, shoe covers and masks.

This incubator itself, the first thing we were led here, to show how the report begins production. Hatching eggs produced on "Nadezhdinskaya poultry farm" and brought here.

Since bookmarks eggs in an incubator until the chicken is held 21 days after they are populated into the house, where they spend 42 days prior to slaughter. Incubator temperature was 37, 6.

Another incubator since vyluplivivshimsya chickens. After the appearance of chicken incubator employees inspect each one, then vaccinate and send chickens in poultry houses.

Sorting and cleaning chickens from the shell. At the same time there is a check on its viability, it is placed on the back to see if he can stand on their own, and if he had inhaled the navel. The factory employs many immigrants from Central Asia, however, according to the director, the problem of alcoholism in the production they are not worried.

This chick has not passed the test of aptitude.

Warm chicken brotherhood.

OTV-Schnick was not easy, we quickly moved from one sector to another.

Before sending in the farm, the chickens are placed in the basket. The Director-General IB, Gregory Patrushev, vladmamam shows and tells how and what was going on.

Chicken feels incredibly nice and warm. His fate did not want to think.

In this light, a la "The Matrix" chickens were fed and they grow-grow-grow. It turned out that the green light is ideal for the development of bird.

The factory is used as the floor and the cell system of poultry. Before us is a cell.

Chickens fed forage from different grains (wheat, corn, soybeans), concentrate feed (soy, sunflower), there are minerals, protein materials, vegetable oil. At MB own feed mill.

This house with a floor system of poultry. Feeling psychedelic not leave.

Here it is, our northern eagle!

Older birds are in a different house. Unlike active chickens, they are moved by a measured area.

Director of the factory Grigory Patrushev is surrounded by member "Vladmama" and journalists on the background of the feed mill MB.

Inside the feed mill. In the day to feed the chick takes about 2, 5 wagons feed (110-130 tons). The plant - the pride of MB, in addition to its own stores of grain and railway siding, by which the delivery of raw materials for animal feed.

The process of mixing of feed is controlled by the operator using the computer system of the plant, with mathematical precision.

The plant produces 5 types of feed for your chickens every age. On the left side marker blackboard written vitamin supplements.

Before you get into the industrial complex, you need to be cleaned with brushes.

Upon reaching 42 days of age, chickens delivered from the poultry houses in the complex poultry processing, where the number of processing steps. Before slaughter of birds stunned shock. Then comes the removal of plumage and gutting.

This picture may be left without comment.

Fully refined bird enters the chamber droplet cooling. To carcasses not zavetrivalis not blush, here are constantly sprayed moisture. Powered photographer VL.RU.

After cooling, the chicks are sorted with the mandatory health kontrolem.Otobrannye broilers are sent to the shop cutting and packaging.

The production complex, even as the people working arrangements, practice and experience of doing their job.

Another phase of cutting.

Packing and packaging whole carcases before being sent to the storage chamber.

They make sausages "Egerskie."

Workshop packing products MB.

Finished products "Mikhailovsky Broiler".

via lena-ryzhaya LJ

Source: