888

Cushioncraft

Material From

Photo ~ 30 + video

The article focuses on Radio-controlled model of the hovercraft made from the very beginning, having only a distant view of the hovercraft and a little money.

Under the cut a lot of pictures.

The idea

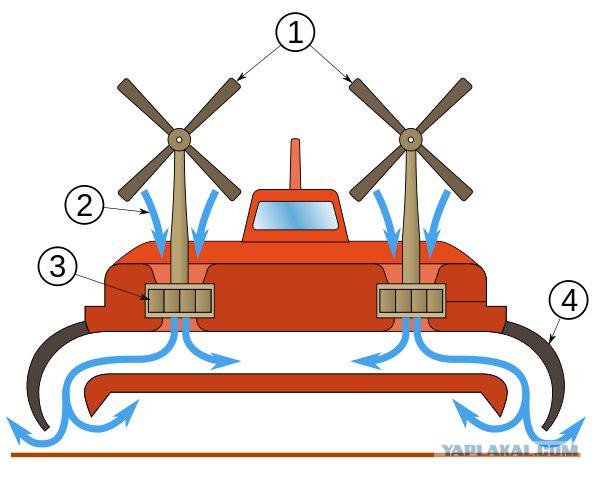

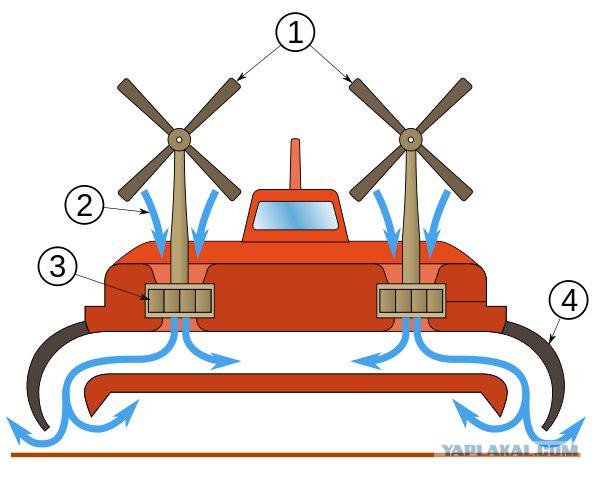

Of course it is crazy, but only partly. As a result, we wanted to get a radio-controlled model hovercraft capable to fly small obstacles (like ekranoplans Class B or C). This was planned to establish a vision system capable of detecting obstacles and help in overcoming them or determine their own kind, and follow them. Yes, if the project will bring to the mind, it will be a group of the SVP, which will only need to manage one of them.

From idea to action

Did we all "by eye", with only an idea of the working principle MRAs, so any comment on the material and equipment very welcome. We used such:

penoplex - 2 (3) pieces 500 p. (750 p.)

double-sided tape cloth - 1 piece 50 p.

Polystyrene - 2 * 1, 5 meters 900 p.

engine - 2 (4) pieces 3110 p. (6220 p.)

speed control - 2 (3) pieces 2540 p. (3810 p.)

propeller - 2 (7-10) p 300 pieces. (600 p.)

Servo - 1 piece free

6-channel radoupravlenie - 1 set free

glue "Titan" - 1 piece 80 p.

Battery - 2 pieces 2360 p.

Medical oilcloth - 1 (3) pieces 100 p. (300 p.)

The pleasure of working - and a lot of priceless

Total: 9940 p. (15070 p.)

In brackets are the number of pieces, and the amount that we spent, although, apparently, could save considerably.

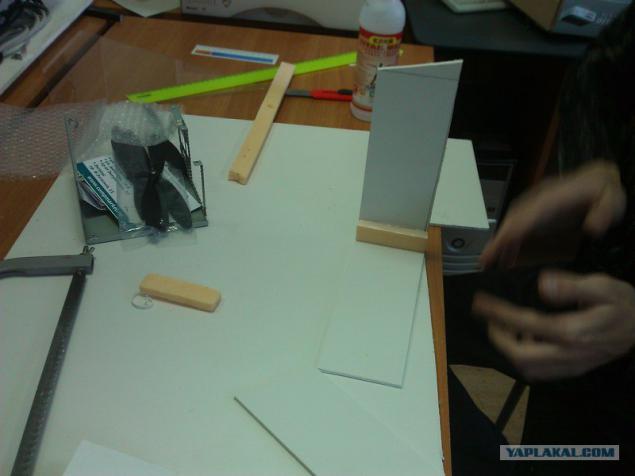

Now, for each item separately in the course of this work. The assembly process

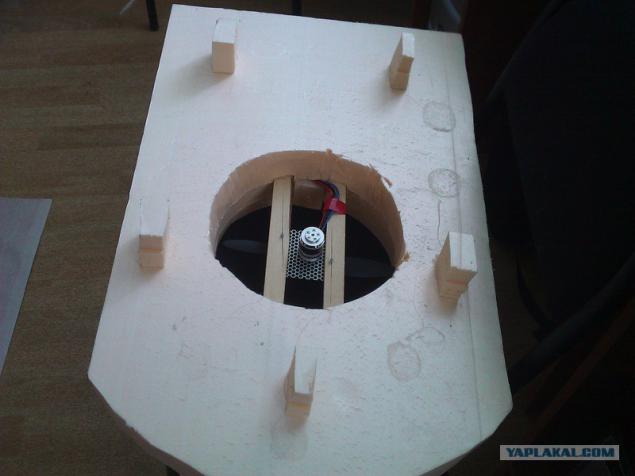

The first thing bought penoplex, tape, glue and ordered 2 engine, 2 batteries, 2 sets of propellers. 6-channel radio equipment we inherited from the previous student (yes, we all gathered at the department in his native Saratov State Technical University). On arrival the first engine, we also burned the first case, it is connected directly to the battery. Yes, it was a great folly, but we realized that without speed regulators we can not do. We ordered regulators, charger for batteries, and started assembling the housing.

Posted in [mergetime] 1330333183 [/ mergetime]

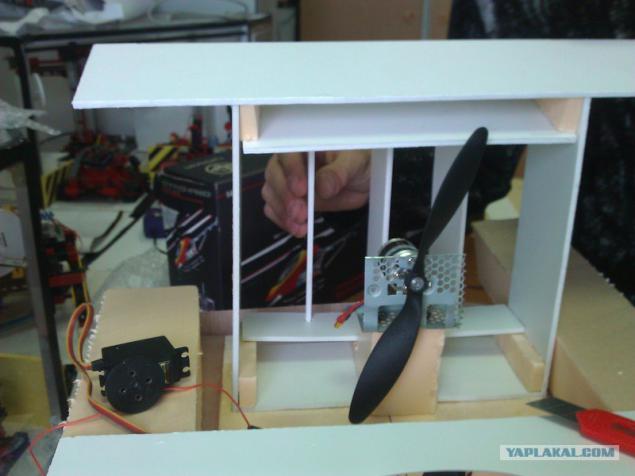

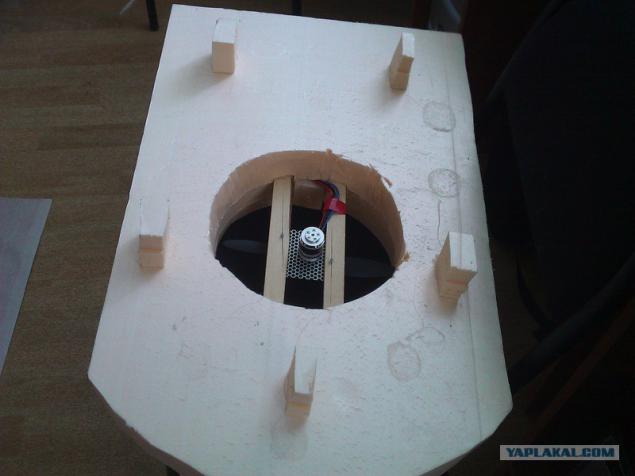

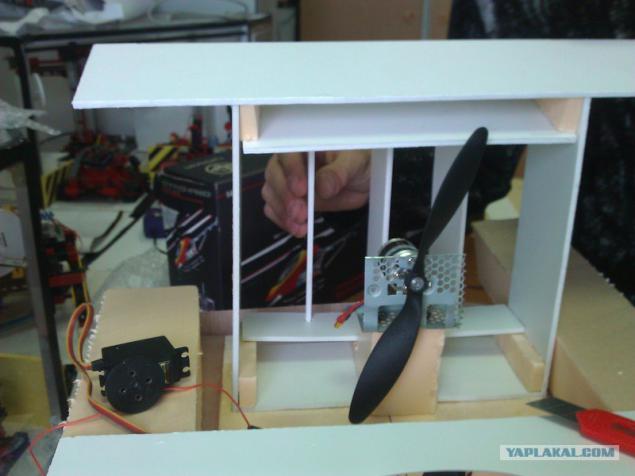

Such a result we did not wait. We thought that the power will be less, and it even without air cushion perfectly raised above the surface of the body even at 50% capacity.

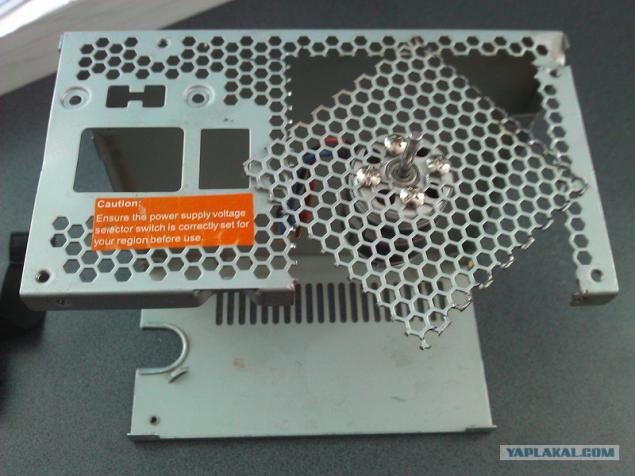

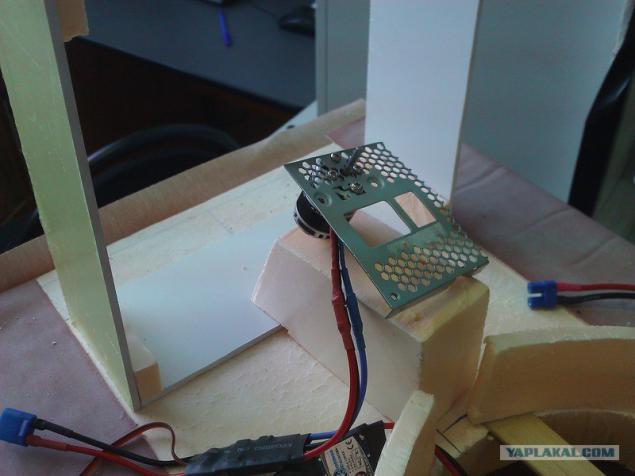

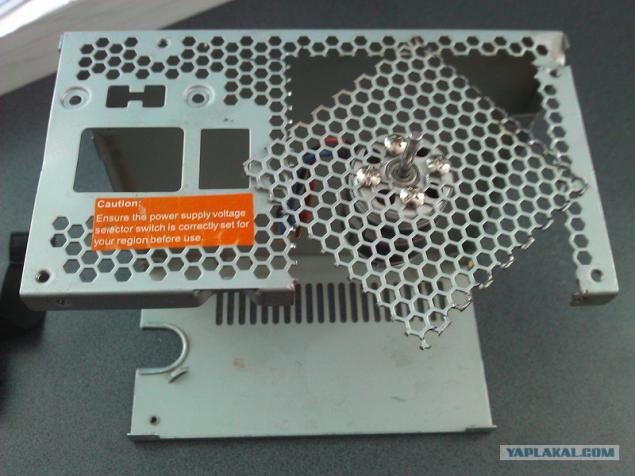

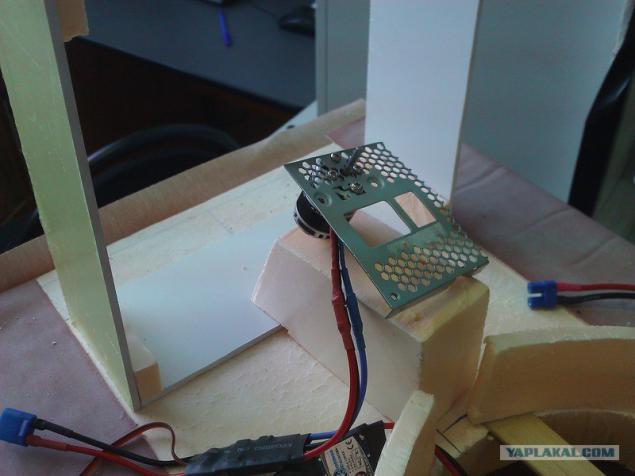

Holder for cut from motor housing PSU.

Two

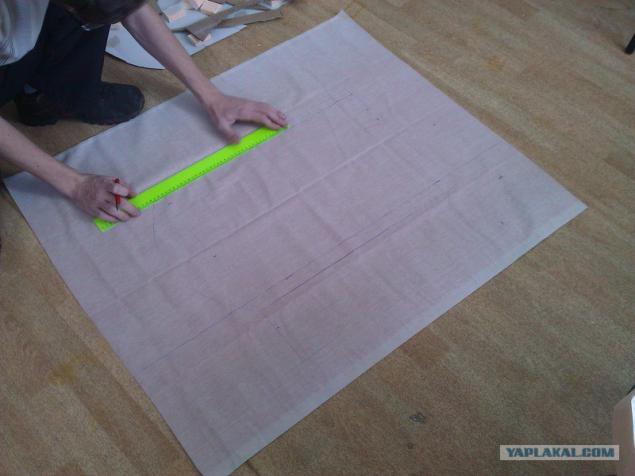

For the first time decided to make a skirt of the pieces of the film, after cutting it, but nothing good we have failed, so the second time made from a single piece, carved in the middle of it.

Skirt we did here on this principle:

Therefore, further the process of gluing the bottom of the skirt:

Two

Three

Four

Posted in [mergetime] 1330333391 [/ mergetime]

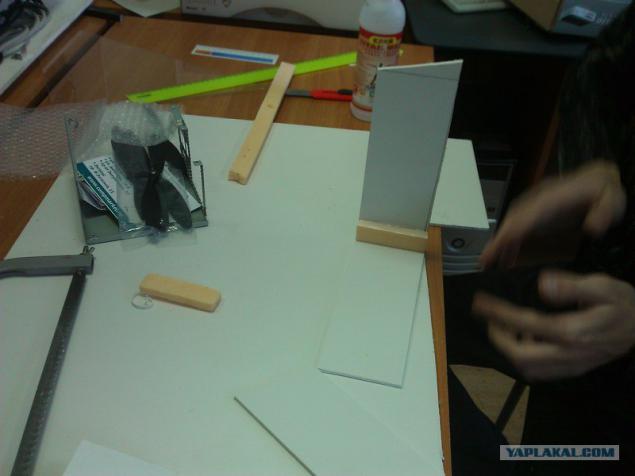

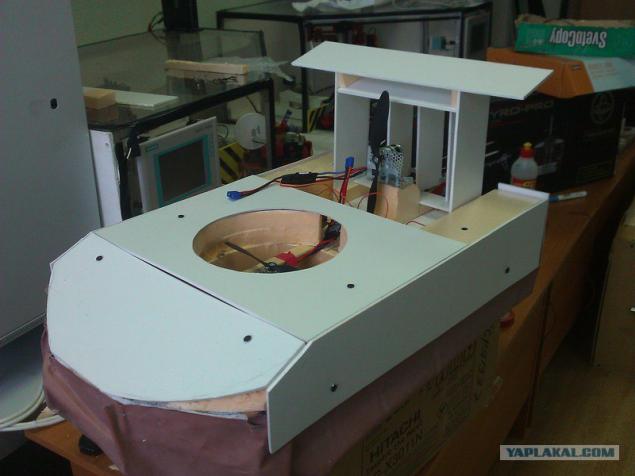

Finally, we found the money for another 1 engine (already the third), and while he was flying to us from St. Petersburg, we started to do a tail part of polystyrene.

Two

Three

Four

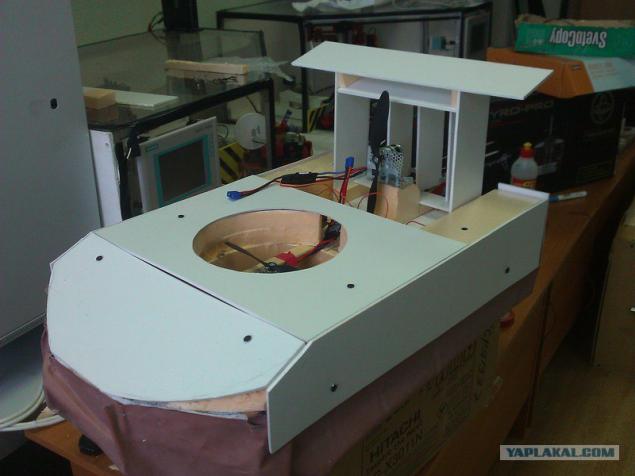

The result was like this:

From the remnants of the housing made holder for the second motor

All of this tie to Penoplex using long screws. To my surprise, holding tightly.

On the last day they decided to finish the job. Add a little more Penoplex to shape and conceal ugliness, it cut container for batteries and servos.

Two

Trim and rudders decided to make the same polystyrene.

Two

Three

Four

The system of rotation control surfaces made from parts left over from the old manipulator.

Two

At the moment, it looks that way.

I noticed that the quality of the photo on the picture, summarized, but all claim to the HTC Mozart. That it removes all photos and videos, as has always been at hand.

Now we look forward to the arrival of a new propulsion engine to replace burned on the last video (yes, terrible smell of singed and it turned out that more SVP does not go forward, the controller does not work, and the motor winding oplavilas). Be sure to add video tests in the field (ie, outdoors).

Posted in [mergetime] 1330333668 [/ mergetime]

Further plans

Let us now we are completely electronically. The benefit of weight gain and little to inflate the skirt is now used only 35% of the engine power. Therefore, we plan to establish e-box 3310A and Kinect, a place for them, and power there. They will serve as a vision system. And on the wing until I can not say, because the outdoors is first necessary to drive the hovercraft, but we'll see.

Source:

Photo ~ 30 + video

The article focuses on Radio-controlled model of the hovercraft made from the very beginning, having only a distant view of the hovercraft and a little money.

Under the cut a lot of pictures.

The idea

Of course it is crazy, but only partly. As a result, we wanted to get a radio-controlled model hovercraft capable to fly small obstacles (like ekranoplans Class B or C). This was planned to establish a vision system capable of detecting obstacles and help in overcoming them or determine their own kind, and follow them. Yes, if the project will bring to the mind, it will be a group of the SVP, which will only need to manage one of them.

From idea to action

Did we all "by eye", with only an idea of the working principle MRAs, so any comment on the material and equipment very welcome. We used such:

penoplex - 2 (3) pieces 500 p. (750 p.)

double-sided tape cloth - 1 piece 50 p.

Polystyrene - 2 * 1, 5 meters 900 p.

engine - 2 (4) pieces 3110 p. (6220 p.)

speed control - 2 (3) pieces 2540 p. (3810 p.)

propeller - 2 (7-10) p 300 pieces. (600 p.)

Servo - 1 piece free

6-channel radoupravlenie - 1 set free

glue "Titan" - 1 piece 80 p.

Battery - 2 pieces 2360 p.

Medical oilcloth - 1 (3) pieces 100 p. (300 p.)

The pleasure of working - and a lot of priceless

Total: 9940 p. (15070 p.)

In brackets are the number of pieces, and the amount that we spent, although, apparently, could save considerably.

Now, for each item separately in the course of this work. The assembly process

The first thing bought penoplex, tape, glue and ordered 2 engine, 2 batteries, 2 sets of propellers. 6-channel radio equipment we inherited from the previous student (yes, we all gathered at the department in his native Saratov State Technical University). On arrival the first engine, we also burned the first case, it is connected directly to the battery. Yes, it was a great folly, but we realized that without speed regulators we can not do. We ordered regulators, charger for batteries, and started assembling the housing.

Posted in [mergetime] 1330333183 [/ mergetime]

Such a result we did not wait. We thought that the power will be less, and it even without air cushion perfectly raised above the surface of the body even at 50% capacity.

Holder for cut from motor housing PSU.

Two

For the first time decided to make a skirt of the pieces of the film, after cutting it, but nothing good we have failed, so the second time made from a single piece, carved in the middle of it.

Skirt we did here on this principle:

Therefore, further the process of gluing the bottom of the skirt:

Two

Three

Four

Posted in [mergetime] 1330333391 [/ mergetime]

Finally, we found the money for another 1 engine (already the third), and while he was flying to us from St. Petersburg, we started to do a tail part of polystyrene.

Two

Three

Four

The result was like this:

From the remnants of the housing made holder for the second motor

All of this tie to Penoplex using long screws. To my surprise, holding tightly.

On the last day they decided to finish the job. Add a little more Penoplex to shape and conceal ugliness, it cut container for batteries and servos.

Two

Trim and rudders decided to make the same polystyrene.

Two

Three

Four

The system of rotation control surfaces made from parts left over from the old manipulator.

Two

At the moment, it looks that way.

I noticed that the quality of the photo on the picture, summarized, but all claim to the HTC Mozart. That it removes all photos and videos, as has always been at hand.

Now we look forward to the arrival of a new propulsion engine to replace burned on the last video (yes, terrible smell of singed and it turned out that more SVP does not go forward, the controller does not work, and the motor winding oplavilas). Be sure to add video tests in the field (ie, outdoors).

Posted in [mergetime] 1330333668 [/ mergetime]

Further plans

Let us now we are completely electronically. The benefit of weight gain and little to inflate the skirt is now used only 35% of the engine power. Therefore, we plan to establish e-box 3310A and Kinect, a place for them, and power there. They will serve as a vision system. And on the wing until I can not say, because the outdoors is first necessary to drive the hovercraft, but we'll see.

Source: