629

My version of Nixie clock

Hello. Not so long ago on Yap had a similar theme. forum2/st/0/topic540230.html

I saw and thought that, too, can make such a , in general, gone.

At the end of the video will be.

Impatient here: rk-stud.ru/2013/03/manicotto-doro/

As usual, I first make a 3D model of the object manufactured

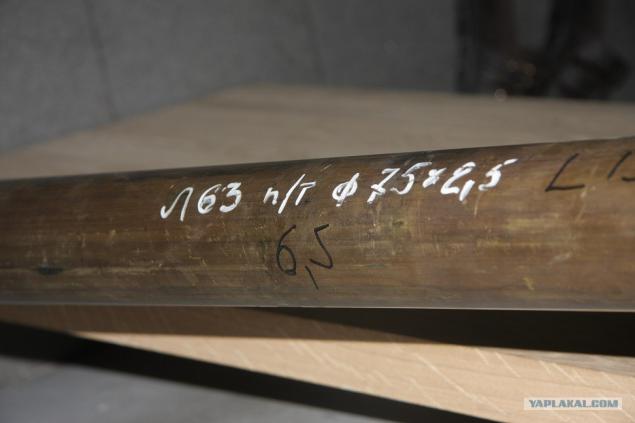

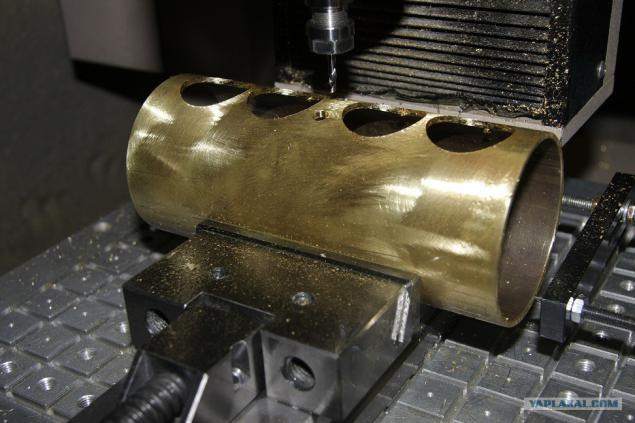

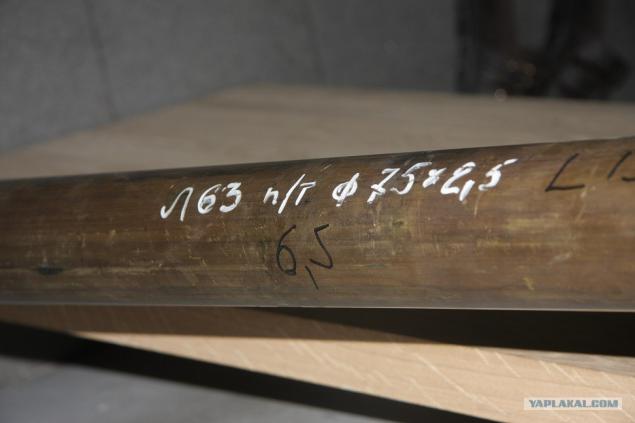

After a successful modeling and drawing creation can start manufacturing. Brass tube cut into blanks.

Billets

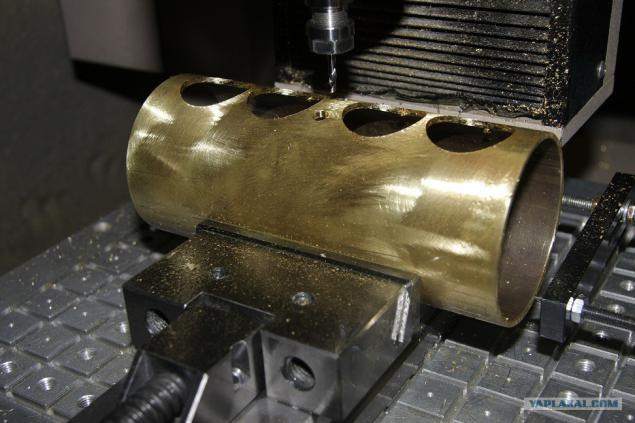

Similarly frezeruem hole LEDs and buttons.

almost ready

Now it's up to the wooden covers. They are made of oak. From blanks (panels) cut a circular piece.

milling

The lathe do rounding in the dividing head drill holes for legs.

holes frezeruem

I wanted to gloss over from the body. Now he polished surface (risks are taking place), and because the preform was crooked, there are potholes in large quantities. They are wanted izbavitsya.Skazano - sdelano.Snachala machined boss, which clamped between the body in a lathe (one boss with a hole for the center, the second - just Rout in the cartridge and left there.

And then just - insert body podzhivaet tailstock (center) and rushed. Removal rates of approximately 0, 1-0, 2 mm, feed rate of 60 mm / min. With each new sёmom formed more and more schools.

Two body in comparison.

Posted in [mergetime] 1363590846 [/ mergetime]

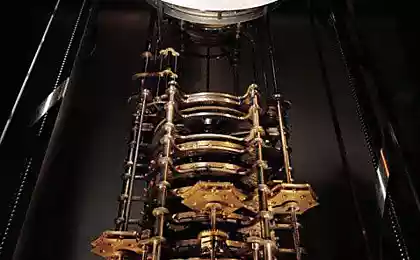

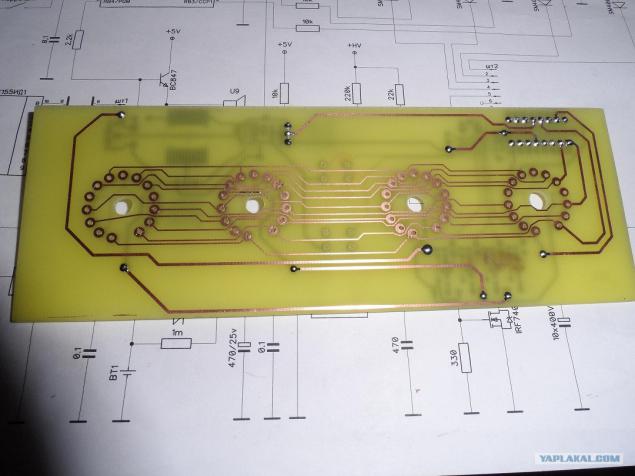

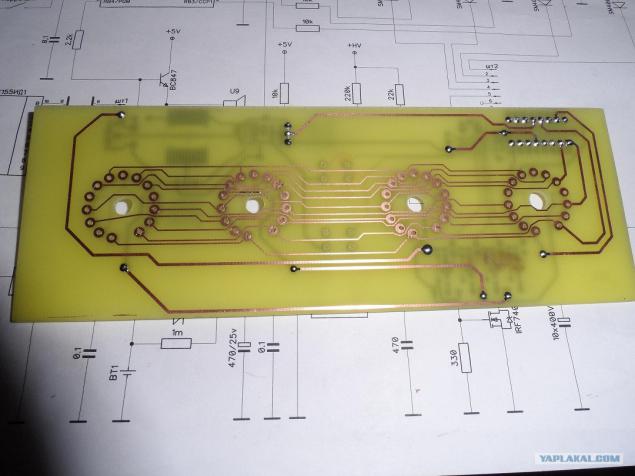

By this time almost made one charge on hours discharge indicators (Nixie Clock).

Posted in [mergetime] 1363590859 [/ mergetime]

photo cards are not attached itself (

damn what))

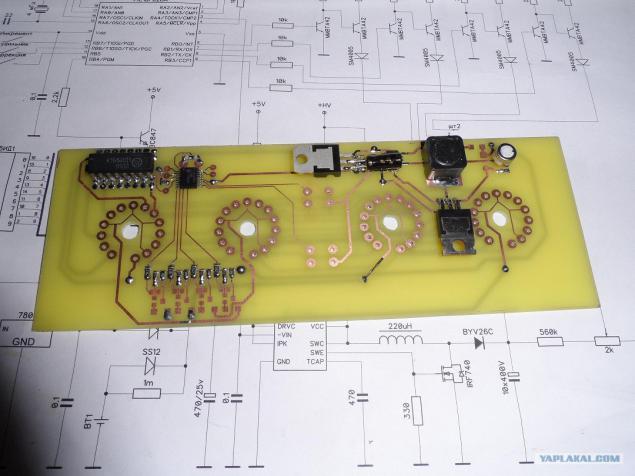

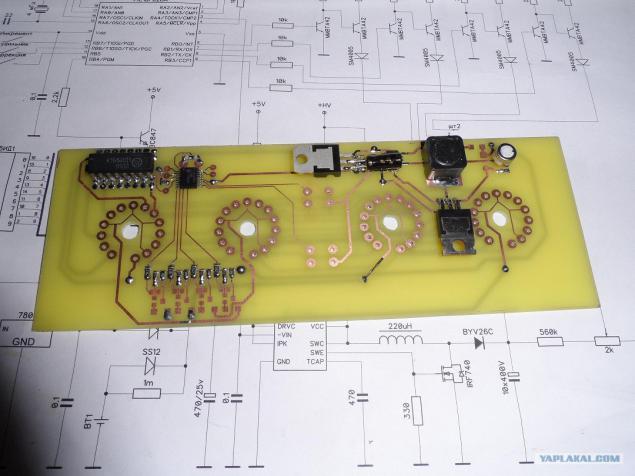

and further. Not all parts are soldered

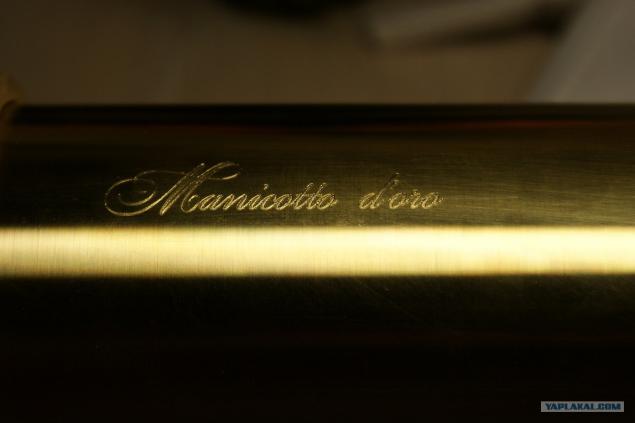

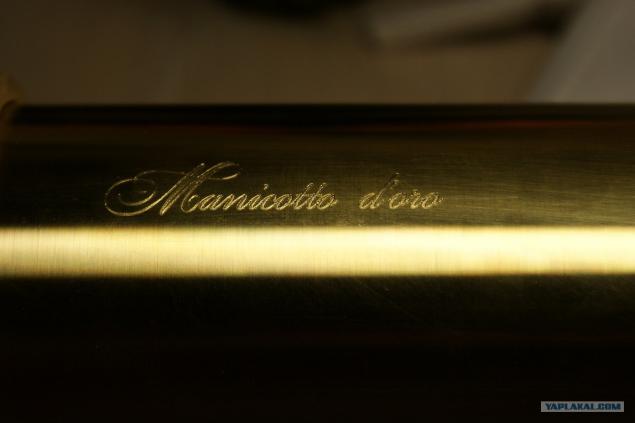

Use the service in a shopping center, struck the inscription on the watch.

a little farther

Well, in this production of WCC chasey completed. It remains only to put it all in one device. Spread all of the elements on the table hours.

Insert the legs (stainless steel) in the end caps (oak). The keys fix tips (stainless steel).

Button tips

Priruchivaem power connector, close the cover body.

housing assembly

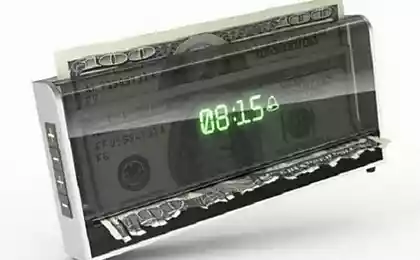

Some photos finished her watch:

More:

and more

so in the dark:

Posted in [mergetime] 1363591268 [/ mergetime]

Well, the promised video:

this I have everything.

Source:

I saw and thought that, too, can make such a , in general, gone.

At the end of the video will be.

Impatient here: rk-stud.ru/2013/03/manicotto-doro/

As usual, I first make a 3D model of the object manufactured

After a successful modeling and drawing creation can start manufacturing. Brass tube cut into blanks.

Billets

Similarly frezeruem hole LEDs and buttons.

almost ready

Now it's up to the wooden covers. They are made of oak. From blanks (panels) cut a circular piece.

milling

The lathe do rounding in the dividing head drill holes for legs.

holes frezeruem

I wanted to gloss over from the body. Now he polished surface (risks are taking place), and because the preform was crooked, there are potholes in large quantities. They are wanted izbavitsya.Skazano - sdelano.Snachala machined boss, which clamped between the body in a lathe (one boss with a hole for the center, the second - just Rout in the cartridge and left there.

And then just - insert body podzhivaet tailstock (center) and rushed. Removal rates of approximately 0, 1-0, 2 mm, feed rate of 60 mm / min. With each new sёmom formed more and more schools.

Two body in comparison.

Posted in [mergetime] 1363590846 [/ mergetime]

By this time almost made one charge on hours discharge indicators (Nixie Clock).

Posted in [mergetime] 1363590859 [/ mergetime]

photo cards are not attached itself (

damn what))

and further. Not all parts are soldered

Use the service in a shopping center, struck the inscription on the watch.

a little farther

Well, in this production of WCC chasey completed. It remains only to put it all in one device. Spread all of the elements on the table hours.

Insert the legs (stainless steel) in the end caps (oak). The keys fix tips (stainless steel).

Button tips

Priruchivaem power connector, close the cover body.

housing assembly

Some photos finished her watch:

More:

and more

so in the dark:

Posted in [mergetime] 1363591268 [/ mergetime]

Well, the promised video:

this I have everything.

Source: