627

Greenhouse-thermos: huge savings on heating!

One of the best, most rational methods in the construction of greenhouses capital — underground greenhouse-thermos.

Using this fact, the constancy of the ground temperature at the depth in the device of the greenhouse gives enormous savings in heating costs in the cold season, facilitates maintenance, makes the climate more stable.

Such a greenhouse works in the most frosts, allows vegetables to grow flowers all year round.

Buried properly equipped greenhouse gives you the opportunity to grow, including heat-loving southern culture. There are practically no restrictions. In the greenhouse, you can feel citrus and even pineapple.

But in practice, all function properly, be sure to respect time-tested technology, which is built underground greenhouse.

After all, this idea is not new, even with the king in Russia buried greenhouses gave yields of pineapples, which enterprising merchants exported for sale in Europe.

Somehow, the construction of such greenhouses is not found in our country a large spread, by and large, it is simply forgotten, although the design is perfect for our climate.

Probably, the role was played by the necessity of digging deep pit, casting of Foundation.

Construction employers greenhouses are quite expensive, this is not a greenhouse covered with polyethylene, but the returns from the greenhouse much more.

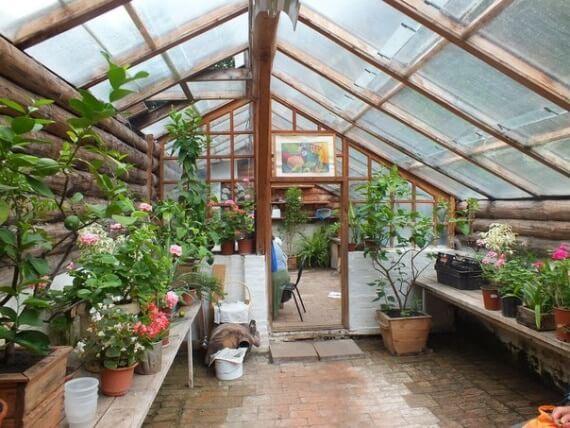

From penetration into the ground is not lost, the total internal illuminance, it may seem strange, but in some cases svetozashitnogo even higher than that of classic greenhouses.

Not to mention the strength and reliability of a design, it is incomparably stronger than usual, easier to withstand hurricane gusts of wind, resists hail, will not be a hindrance and piles of snow.

1. Pit

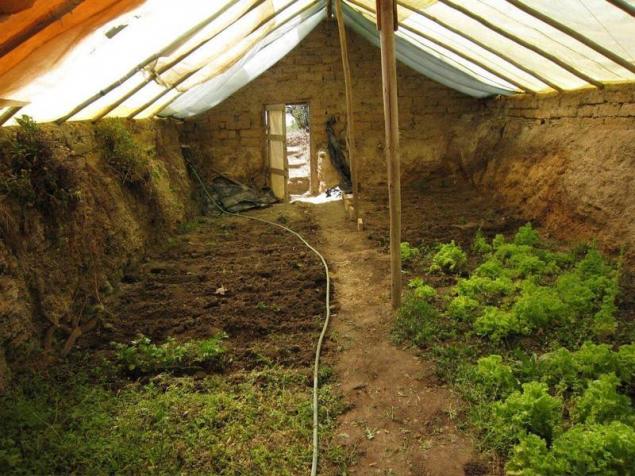

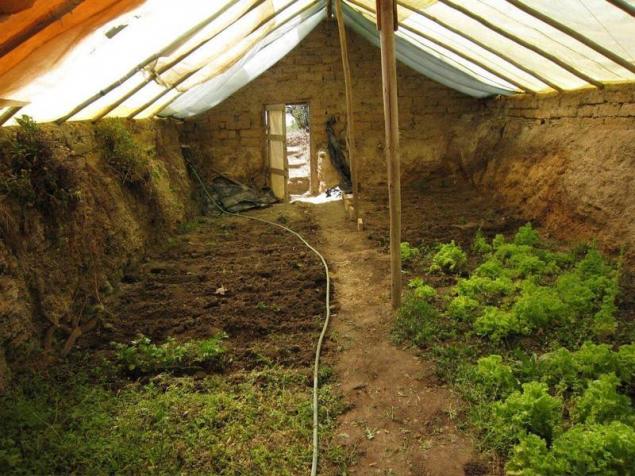

The creation of greenhouses begins with excavation. To use the earth's heat for heating the internal volume of the greenhouse must be sufficiently deepened. The deeper, the earth becomes warmer.

The temperature is almost not changed during the year at a distance of 2-2,5 meters from the surface. At a depth of 1 m, the temperature of the soil fluctuates more, but in winter its value remains positive, usually in the middle zone temperature is 4-10 S, depending on the time of year.

Recessed greenhouse is being built in one season. That winter she was quite able to function and generate income. Construction is not cheap, but by applying ingenuity, compromise materials, it is possible to save literally an order of magnitude, making a kind of economy version of the greenhouse, starting with the pit.

For example, to dispense with the bringing of construction equipment. Although the most time-consuming part of the work — digging a ditch - of course, it is better to give the excavator. Manually remove such amount of earth hard and long.

Pit depth of the pit should not be less than two meters. At this depth, the earth will begin to share its warmth and work as a kind of thermos. If the depth is smaller, then in principle the idea would work, but noticeably less effective. Therefore, it is recommended not to regret forces and means to deepening the future of the greenhouse.

In length of underground greenhouses can be arbitrary, but the width it's better to sustain within 5 meters, if the width is more, the deteriorating quality characteristics for heat and light reflectance.

To the horizon of the underground greenhouses to target is necessary, as conventional greenhouses and greenhouses, from East to West, that is, so that one side was facing South. In this position, the plants will receive the maximum amount of solar energy.

2. The walls and roof

Around the perimeter of the pit pour the Foundation or lay out the blocks. The Foundation serves as a basis for wall and frame structures. Wall is better to make materials with good insulation characteristics, a nice option is the fuser.

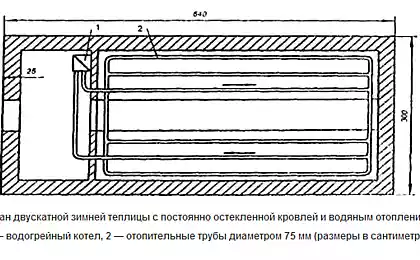

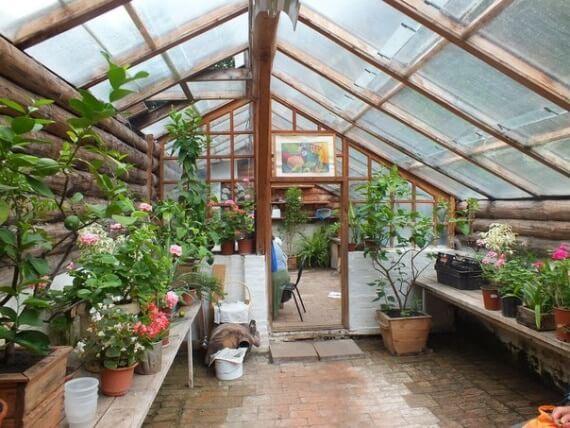

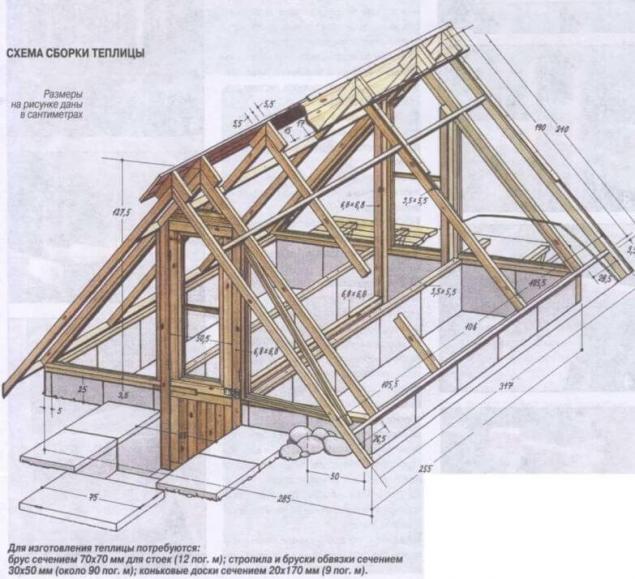

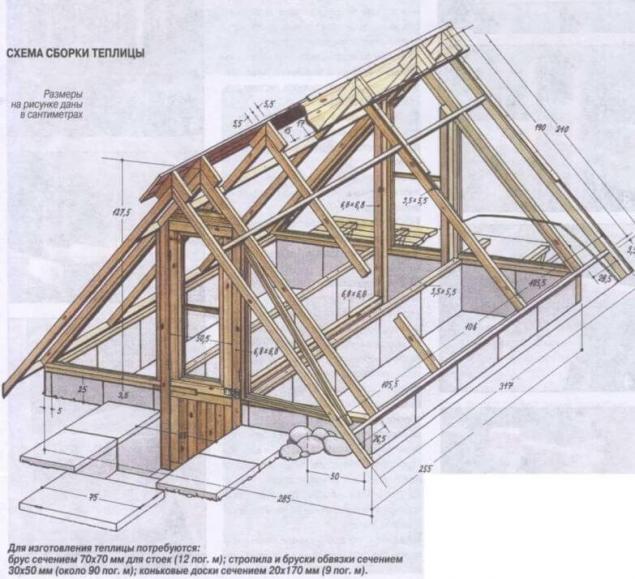

The roof frame is often made of wood, of impregnated antiseptic bars. The roof structure is usually a straight gable. In the center of the design reinforce the ridge beam, on the floor set the Central support along the entire length of the greenhouse.

Ridge beam and the walls are connected by a number of rafters. The frame can be done without high supports. They're replaced by small, which put on a cross beam connecting the opposite side of the greenhouse — this design makes the interior space more freely.

As a roof coating it is better to take polycarbonate is a popular modern material. The distance between the rafters in the construction to fit the width of the polycarbonate sheets. To work with the material is comfortable. The coating is obtained with a small number of joints, so the sheets are produced with a length of 12 m.

To the frame they are mounted with screws, it is better to choose with a hat in the form of a washer. In order to avoid cracking of the sheet under each screw need to drill a drill hole of appropriate diameter. With the help of a screwdriver, or a regular drill with a cross bat, the work on the glazing moves very quickly.

In order to leave no gaps, well in advance on top of the rafters to lay a seal of soft rubber or other suitable material and only then to fasten sheets.

The peak of the roof along the ridge you need to lay a soft insulation and to press some area: plastic, steel, of other suitable material.

For good insulation the roof is sometimes made with a double layer of polycarbonate. Although transparency is reduced by about 10%, but it is covered with excellent insulating characteristics.

You need to consider that snow on a roof melts. Therefore, the slope should be under a sufficient angle at least 30 degrees, so the snow on the roof doesn't accumulate. In addition to shaking put an electric vibrator, it will protect the roof if the snow will still accumulate.

Double glazing making in two ways:

3. Insulation and heating

Wall insulation is carried out as follows. Pre-need to carefully mark the solution all joints and seams of the wall here can be applied to the foam. The inner side walls of the cover film thermal insulation.

In cold parts of the country make good use of foil thick film, covering the wall double layer.

The temperature in the deep soil of the greenhouse above freezing, but colder than the air temperature required for plant growth. The top layer is warmed by sunlight and air of the greenhouse, but the soil absorbs the heat so often in the underground greenhouses are using technology "warm floor"heating element — electric cable protect metal grate or filled with concrete.

In the second case, soil for raised beds is poured on top of concrete or herbs are grown in pots and vases.

The use of floor heating may be sufficient to heat the whole greenhouse, if you have enough power.

But it is more effective and more comfortable for plants using combined heating: warm floors + heated air. For good growth they need a temperature of 25-35 degrees with the ground temperature of about 25 C.

CONCLUSION

Of course, building embedded greenhouses will cost more, but the effort will require more than the construction of a similar greenhouse of conventional design. But nested in the greenhouse-the thermos tools over time are justified.

First, it saves energy on heating. In all heated in winter common ground greenhouse, it will always be more expensive and harder similar method of heating in an underground greenhouse.

Secondly, the savings on lighting. Foil-insulation of the walls, reflecting the light increases the illumination in two times.

The microclimate in the deep winter greenhouse for plants is more favorable, which will certainly affect yields. Easily take root seedlings, perfectly will feel tender plants.

This greenhouse ensures a stable, high yield of all plants all year round.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.pervorod.ru/blogs/eto-interesno/teplitsa-termos

Using this fact, the constancy of the ground temperature at the depth in the device of the greenhouse gives enormous savings in heating costs in the cold season, facilitates maintenance, makes the climate more stable.

Such a greenhouse works in the most frosts, allows vegetables to grow flowers all year round.

Buried properly equipped greenhouse gives you the opportunity to grow, including heat-loving southern culture. There are practically no restrictions. In the greenhouse, you can feel citrus and even pineapple.

But in practice, all function properly, be sure to respect time-tested technology, which is built underground greenhouse.

After all, this idea is not new, even with the king in Russia buried greenhouses gave yields of pineapples, which enterprising merchants exported for sale in Europe.

Somehow, the construction of such greenhouses is not found in our country a large spread, by and large, it is simply forgotten, although the design is perfect for our climate.

Probably, the role was played by the necessity of digging deep pit, casting of Foundation.

Construction employers greenhouses are quite expensive, this is not a greenhouse covered with polyethylene, but the returns from the greenhouse much more.

From penetration into the ground is not lost, the total internal illuminance, it may seem strange, but in some cases svetozashitnogo even higher than that of classic greenhouses.

Not to mention the strength and reliability of a design, it is incomparably stronger than usual, easier to withstand hurricane gusts of wind, resists hail, will not be a hindrance and piles of snow.

1. Pit

The creation of greenhouses begins with excavation. To use the earth's heat for heating the internal volume of the greenhouse must be sufficiently deepened. The deeper, the earth becomes warmer.

The temperature is almost not changed during the year at a distance of 2-2,5 meters from the surface. At a depth of 1 m, the temperature of the soil fluctuates more, but in winter its value remains positive, usually in the middle zone temperature is 4-10 S, depending on the time of year.

Recessed greenhouse is being built in one season. That winter she was quite able to function and generate income. Construction is not cheap, but by applying ingenuity, compromise materials, it is possible to save literally an order of magnitude, making a kind of economy version of the greenhouse, starting with the pit.

For example, to dispense with the bringing of construction equipment. Although the most time-consuming part of the work — digging a ditch - of course, it is better to give the excavator. Manually remove such amount of earth hard and long.

Pit depth of the pit should not be less than two meters. At this depth, the earth will begin to share its warmth and work as a kind of thermos. If the depth is smaller, then in principle the idea would work, but noticeably less effective. Therefore, it is recommended not to regret forces and means to deepening the future of the greenhouse.

In length of underground greenhouses can be arbitrary, but the width it's better to sustain within 5 meters, if the width is more, the deteriorating quality characteristics for heat and light reflectance.

To the horizon of the underground greenhouses to target is necessary, as conventional greenhouses and greenhouses, from East to West, that is, so that one side was facing South. In this position, the plants will receive the maximum amount of solar energy.

2. The walls and roof

Around the perimeter of the pit pour the Foundation or lay out the blocks. The Foundation serves as a basis for wall and frame structures. Wall is better to make materials with good insulation characteristics, a nice option is the fuser.

The roof frame is often made of wood, of impregnated antiseptic bars. The roof structure is usually a straight gable. In the center of the design reinforce the ridge beam, on the floor set the Central support along the entire length of the greenhouse.

Ridge beam and the walls are connected by a number of rafters. The frame can be done without high supports. They're replaced by small, which put on a cross beam connecting the opposite side of the greenhouse — this design makes the interior space more freely.

As a roof coating it is better to take polycarbonate is a popular modern material. The distance between the rafters in the construction to fit the width of the polycarbonate sheets. To work with the material is comfortable. The coating is obtained with a small number of joints, so the sheets are produced with a length of 12 m.

To the frame they are mounted with screws, it is better to choose with a hat in the form of a washer. In order to avoid cracking of the sheet under each screw need to drill a drill hole of appropriate diameter. With the help of a screwdriver, or a regular drill with a cross bat, the work on the glazing moves very quickly.

In order to leave no gaps, well in advance on top of the rafters to lay a seal of soft rubber or other suitable material and only then to fasten sheets.

The peak of the roof along the ridge you need to lay a soft insulation and to press some area: plastic, steel, of other suitable material.

For good insulation the roof is sometimes made with a double layer of polycarbonate. Although transparency is reduced by about 10%, but it is covered with excellent insulating characteristics.

You need to consider that snow on a roof melts. Therefore, the slope should be under a sufficient angle at least 30 degrees, so the snow on the roof doesn't accumulate. In addition to shaking put an electric vibrator, it will protect the roof if the snow will still accumulate.

Double glazing making in two ways:

- Between the two sheets are inserted special profile sheets are attached to the frame at the top.

- First, attach the bottom layer of glazing to the frame from the inside, to the underside of the rafters. The second layer of the roof is available, as usual on.

3. Insulation and heating

Wall insulation is carried out as follows. Pre-need to carefully mark the solution all joints and seams of the wall here can be applied to the foam. The inner side walls of the cover film thermal insulation.

In cold parts of the country make good use of foil thick film, covering the wall double layer.

The temperature in the deep soil of the greenhouse above freezing, but colder than the air temperature required for plant growth. The top layer is warmed by sunlight and air of the greenhouse, but the soil absorbs the heat so often in the underground greenhouses are using technology "warm floor"heating element — electric cable protect metal grate or filled with concrete.

In the second case, soil for raised beds is poured on top of concrete or herbs are grown in pots and vases.

The use of floor heating may be sufficient to heat the whole greenhouse, if you have enough power.

But it is more effective and more comfortable for plants using combined heating: warm floors + heated air. For good growth they need a temperature of 25-35 degrees with the ground temperature of about 25 C.

CONCLUSION

Of course, building embedded greenhouses will cost more, but the effort will require more than the construction of a similar greenhouse of conventional design. But nested in the greenhouse-the thermos tools over time are justified.

First, it saves energy on heating. In all heated in winter common ground greenhouse, it will always be more expensive and harder similar method of heating in an underground greenhouse.

Secondly, the savings on lighting. Foil-insulation of the walls, reflecting the light increases the illumination in two times.

The microclimate in the deep winter greenhouse for plants is more favorable, which will certainly affect yields. Easily take root seedlings, perfectly will feel tender plants.

This greenhouse ensures a stable, high yield of all plants all year round.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.pervorod.ru/blogs/eto-interesno/teplitsa-termos