434

Unique eco-friendly insulation technology of the XXI century

Insulation technology on the basis of spray polyurethane foam is being actively used worldwide.

We have long been used to insulate homes, building companies, pipelines and other structures the old-fashioned way: brick, mineral wool, and other fibrous materials.However, they were replaced by modern technology, with absolute friendliness and unique properties. Talking about the latest polymer system on the basis of spray polyurethane foam (PUR).

Currently, this technology is widely used around the world and in the United States and Canada is the main. By the way, the Japanese 30 years ago, experiments were conducted on its application and proved the uniqueness. Since the thermal insulation by spraying polyurethane foam remains unsurpassed in its characteristics.

PRP and its benefits

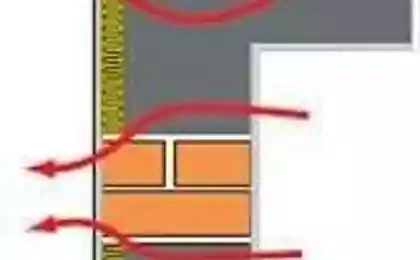

What is polyurethane foam? It kind of foams with a cellular structure filled with air. Get it by mixing two components: polyol and polyisocyanate. Getting in an open environment, a mixture of foaming increases to a certain extent and solidified. The result is a smooth, seamless surface, with the effective coefficient of heat, hydro, steam and sound insulation.spraying of polyurethane foam

Since we're talking about insulation, will give the specific numbers. The thermal conductivity of PUF is only 0,02-0,04 W/(m2*K). That is, when applying a layer of 39 mm, it will have the same rate of heat as 100 cm sand-lime brick or 8.1 cm of mineral wool, or 7.5 cm of fiberglass or 6.6 cm of basalt fiber, or 6.1 cm polystyrene, or 4.7 cm penoizol.

But that's not all. Polyurethane foam can be applied on any surface (wood, metal, concrete, etc.) and any angle (floor, wall, roof, pipe). It is lightweight, and therefore does not weigh down the structure, does not SAG and does not slip. Thus in the hardened state, fastens, giving additional rigidity to the entire structure. The solidity of the coating guarantees the complete absence of so-called "cold bridges". PUF passive to corrosion (water absorption is only 1-2%), resistant to microorganisms, rodents, ingrown roots and other aggressive environments. Operating temperature range is from -150 °C to +150 °C. the service life of the foam is from 30 to 50 years.

Due to its unique properties, foam holds exactly the set temperature. Moreover, not only positive that can make it an indispensable application in refrigerating systems. Finally, the very high-tech polyurethane foam that is soft, tough, elastic (depending on density and ratio of the components).

Do not forget about its economy. For example, for warming a house with an area of 400 square metres you will need 20 cubic meters teleisolation plates 5 cm thick, which have yet to ship and install. And when using a PPU will need a 4-inch layer with a volume of 16 cubic meters, the weight of which in the form of raw materials will be only 640 kg. This barrel can result in even a small van.

Technology of spraying and recommendations

To complete the process of applying polyurethane foam and high-performance layer the ambient temperature must be at least +5 °C and components – from +10 to +25 °C. However, it is possible to work in sub-zero temperatures, but the mixture it is necessary to heat and maintain in the above-specified range.

It is important to prepare itself teploizolirovan surface: clean dirt and dry. If it's metal, remove rust and degrease. Steel is desirable, and even necessary aluminium primed with the maximum amount of adhesion. For example, inhibitory ground solutions of the type xn-0231 MCH, EP-0199, AK-069. This training will increase the grip with the surface almost twice.

Spraying of polyurethane foam

The process of spraying polyurethane foam consists of several stages. First, the components of polyurethane foam are mixed. Then, with a foam generator (compressor) and spray gun, the mixture is applied to the surface. If necessary, it is possible to apply repeated layers. As mentioned earlier, a polyurethane coating may be of different densities (15 to 70 kg / m3). It depends on the proportions in which the components are mixed. And this factor in turn affects reaction time. That is, a monolithic layer may begin to develop after 1-3 seconds, maybe 10 seconds. Low density foam (25 kg/m3) are only suitable under the lining. Polyurethane foams with a density from 40 kg/m3 for walls and roofs, because they will serve under load. Finally, the coating weight > 60 kg/m3 is recommended for floor screed.

After spray polyurethane foam (outside) for maximum adhesion is highly desirable to apply ogruntovochnye layer. Then, several layers of protective varnish, HSPA, mastic "Krovlelit-FM" and enamel CP-799 MCH.

Raw materials and equipment

In the domestic market of polyurethane foams and systems for their application on various surfaces is represented quite widely. For example, only brands foam more than ten. Perhaps the best are a series Н1611 and Н1612 (Germany), TS (the Netherlands), Demilec (USA), as well as ready Russian PPU: 6N, П002, 17Н, АТ117Н, 17Н-100.

The most modern equipment in the world directly to spray polyurethane foam manufactured by Graco (USA). They can buy a full set for all occasions. In Russia, despite a variety of appropriate equipment, to purchase equipment will have parts. So, a good foam is PRESENT and ultrasonic testing; compressors – For-24 and SB-4; spray guns – PR-6 and FOAM-20. And yet the essential cotton suit, boots (preferably canvas), rubber gloves, gas mask, grade A, BKF or a respirator RPG, but it needs sunglasses and a hat.

Vladislav Permin ©

Source: /users/87

We have long been used to insulate homes, building companies, pipelines and other structures the old-fashioned way: brick, mineral wool, and other fibrous materials.However, they were replaced by modern technology, with absolute friendliness and unique properties. Talking about the latest polymer system on the basis of spray polyurethane foam (PUR).

Currently, this technology is widely used around the world and in the United States and Canada is the main. By the way, the Japanese 30 years ago, experiments were conducted on its application and proved the uniqueness. Since the thermal insulation by spraying polyurethane foam remains unsurpassed in its characteristics.

PRP and its benefits

What is polyurethane foam? It kind of foams with a cellular structure filled with air. Get it by mixing two components: polyol and polyisocyanate. Getting in an open environment, a mixture of foaming increases to a certain extent and solidified. The result is a smooth, seamless surface, with the effective coefficient of heat, hydro, steam and sound insulation.spraying of polyurethane foam

Since we're talking about insulation, will give the specific numbers. The thermal conductivity of PUF is only 0,02-0,04 W/(m2*K). That is, when applying a layer of 39 mm, it will have the same rate of heat as 100 cm sand-lime brick or 8.1 cm of mineral wool, or 7.5 cm of fiberglass or 6.6 cm of basalt fiber, or 6.1 cm polystyrene, or 4.7 cm penoizol.

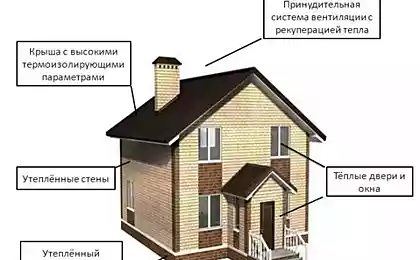

But that's not all. Polyurethane foam can be applied on any surface (wood, metal, concrete, etc.) and any angle (floor, wall, roof, pipe). It is lightweight, and therefore does not weigh down the structure, does not SAG and does not slip. Thus in the hardened state, fastens, giving additional rigidity to the entire structure. The solidity of the coating guarantees the complete absence of so-called "cold bridges". PUF passive to corrosion (water absorption is only 1-2%), resistant to microorganisms, rodents, ingrown roots and other aggressive environments. Operating temperature range is from -150 °C to +150 °C. the service life of the foam is from 30 to 50 years.

Due to its unique properties, foam holds exactly the set temperature. Moreover, not only positive that can make it an indispensable application in refrigerating systems. Finally, the very high-tech polyurethane foam that is soft, tough, elastic (depending on density and ratio of the components).

Do not forget about its economy. For example, for warming a house with an area of 400 square metres you will need 20 cubic meters teleisolation plates 5 cm thick, which have yet to ship and install. And when using a PPU will need a 4-inch layer with a volume of 16 cubic meters, the weight of which in the form of raw materials will be only 640 kg. This barrel can result in even a small van.

Technology of spraying and recommendations

To complete the process of applying polyurethane foam and high-performance layer the ambient temperature must be at least +5 °C and components – from +10 to +25 °C. However, it is possible to work in sub-zero temperatures, but the mixture it is necessary to heat and maintain in the above-specified range.

It is important to prepare itself teploizolirovan surface: clean dirt and dry. If it's metal, remove rust and degrease. Steel is desirable, and even necessary aluminium primed with the maximum amount of adhesion. For example, inhibitory ground solutions of the type xn-0231 MCH, EP-0199, AK-069. This training will increase the grip with the surface almost twice.

Spraying of polyurethane foam

The process of spraying polyurethane foam consists of several stages. First, the components of polyurethane foam are mixed. Then, with a foam generator (compressor) and spray gun, the mixture is applied to the surface. If necessary, it is possible to apply repeated layers. As mentioned earlier, a polyurethane coating may be of different densities (15 to 70 kg / m3). It depends on the proportions in which the components are mixed. And this factor in turn affects reaction time. That is, a monolithic layer may begin to develop after 1-3 seconds, maybe 10 seconds. Low density foam (25 kg/m3) are only suitable under the lining. Polyurethane foams with a density from 40 kg/m3 for walls and roofs, because they will serve under load. Finally, the coating weight > 60 kg/m3 is recommended for floor screed.

After spray polyurethane foam (outside) for maximum adhesion is highly desirable to apply ogruntovochnye layer. Then, several layers of protective varnish, HSPA, mastic "Krovlelit-FM" and enamel CP-799 MCH.

Raw materials and equipment

In the domestic market of polyurethane foams and systems for their application on various surfaces is represented quite widely. For example, only brands foam more than ten. Perhaps the best are a series Н1611 and Н1612 (Germany), TS (the Netherlands), Demilec (USA), as well as ready Russian PPU: 6N, П002, 17Н, АТ117Н, 17Н-100.

The most modern equipment in the world directly to spray polyurethane foam manufactured by Graco (USA). They can buy a full set for all occasions. In Russia, despite a variety of appropriate equipment, to purchase equipment will have parts. So, a good foam is PRESENT and ultrasonic testing; compressors – For-24 and SB-4; spray guns – PR-6 and FOAM-20. And yet the essential cotton suit, boots (preferably canvas), rubber gloves, gas mask, grade A, BKF or a respirator RPG, but it needs sunglasses and a hat.

Vladislav Permin ©

Source: /users/87