186

The use of foil insulation in modern construction

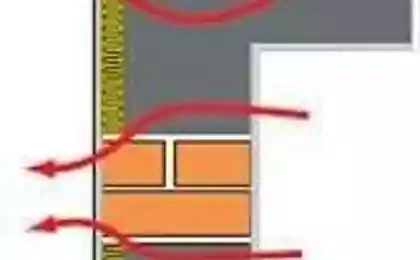

Foil insulation is a thermally insulating combined material coated on one or two sides with polished foil with an aluminum layer or a metalized polypropylene film. The reflection effect, due to the metallic properties of the coating, reaches 97%.

Application:

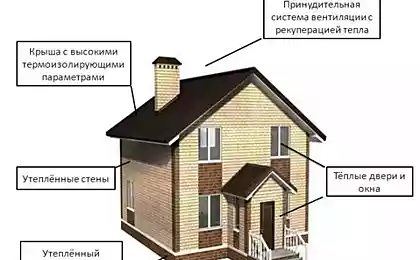

Insulation of pipes of heat networks; Insulation of hot and cold water supply pipes in the engineering networks of the house; Thermal insulation of ducts, ventilation channels in air conditioning and ventilation systems; Use of technological equipment as technical isolation; Thermal insulation of walls, floors in residential and public buildings; Sound insulation of interstitial surfaces. Types of foil insulation

Between the finish and the insulation should leave a gap of up to 25 mm, but not less than 12 mm for additional heat protection. In this case, the aluminum coating will not be heated by direct heat transfer. The remaining visible joints are glued with a special aluminum (foil) tape. This is the final cut.

The cost of any foil insulation is commensurate with the cost of an alternative insulation with similar thermal insulation characteristics. But with the help of foil insulation, you can save on installation time, space (foil insulation is thinner than usual) and get a number of additional bonuses in the form of environmental friendliness, fire resistance, etc.

Depending on the requirements, various foil insulation can be effectively used for thermal insulation of any objects.

Before buying, you need to make sure that the insulation is really covered with aluminum foil, and not aluminum spray. Most likely, the aluminum coating will not work at all.

Source: greenvolt.ru/

Application:

Insulation of pipes of heat networks; Insulation of hot and cold water supply pipes in the engineering networks of the house; Thermal insulation of ducts, ventilation channels in air conditioning and ventilation systems; Use of technological equipment as technical isolation; Thermal insulation of walls, floors in residential and public buildings; Sound insulation of interstitial surfaces. Types of foil insulation

- Foamed polyethylene with foil. It is a multilayer material in the form of a thin roll of foamed polyethylene coated with aluminum foil. May have an adhesive layer in order to ensure convenience and reliability of attachment to surfaces.

Most often used for insulation of floors, roofs, walls, ventilation systems. It is also effective for insulating pipes, ducts and refrigeration equipment. - Mineral wool and foil. Foil insulation with a base in the form of mineral wool. Applied in all types of insulation, it is environmentally friendly and non-combustible material.

Available in the form of rolls (mats), plates and cylinders. It is best suited for insulation of saunas, insulation of baths, roofs, chimneys. For insulation of pipes, this insulation is used in the form of thermal insulation cylinders with mineral wool. - Foil polystyrene foam. As a rule, it is used for thermal insulation of warm water floor systems, acting as a barrier to the passage of heat from heating elements mounted in the floor. Styrofoam is a durable thermal insulation material, retains its properties in the temperature range -180 ° C - +180 ° C.

- Basalt foil insulating material. It is used in various branches of heat power, industry, in aircraft construction, in housing construction and for gas station equipment.

This material is non-combustible and can withstand -200 ° C - + 700 ° C. It has increased resistance to aggressive environments.

- Stability in a large temperature range;

- They do not absorb moisture and have resistance to reflection.

- High heat, steam and waterproofing indicators;

- Eco-friendly;

- Easy and quick installation.

Between the finish and the insulation should leave a gap of up to 25 mm, but not less than 12 mm for additional heat protection. In this case, the aluminum coating will not be heated by direct heat transfer. The remaining visible joints are glued with a special aluminum (foil) tape. This is the final cut.

The cost of any foil insulation is commensurate with the cost of an alternative insulation with similar thermal insulation characteristics. But with the help of foil insulation, you can save on installation time, space (foil insulation is thinner than usual) and get a number of additional bonuses in the form of environmental friendliness, fire resistance, etc.

Depending on the requirements, various foil insulation can be effectively used for thermal insulation of any objects.

Before buying, you need to make sure that the insulation is really covered with aluminum foil, and not aluminum spray. Most likely, the aluminum coating will not work at all.

Source: greenvolt.ru/