176

The main advantages of a gas generator

One of the most pressing problems in the modern world is the need to reduce the cost of electricity. The usual and affordable raw materials for obtaining electricity are peat, firewood, branches, briquettes of sawdust. Modern gas generators are able to work on all of the above. Electricity is cheaper than buying and maintaining a power plant.

A gas generator is a device that converts solid or liquid fuel into a gaseous form.

In its active part, three areas flow into each other: thermal decomposition of fuel, oxidation, recovery.

The gas generator process is of three types:

All devices differ in the system of ash selection and fuel loading. The continuous process is the most technological. Video of the gas generator

Gas generator, working on waste, is sealed. This is confirmed by the fact that the exhaust gases of the engine using generator gas are more environmentally friendly. This cannot be said about the diesel generator. Motor life of engines that run on generator gas, much more than engines running on diesel fuel or gasoline.

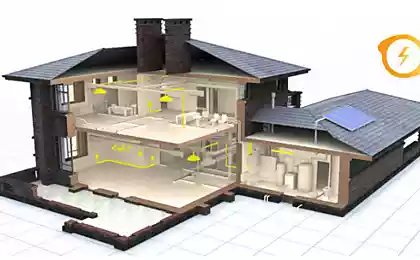

In winter conditions, the gas generator on firewood performs more efficient work due to better filling of the engine cylinders with a working gas mixture. In stationary conditions, you can dispose of the heat generated by the generator, for example, for heating rooms.

Gas generators on solid fuel reduce the emission of harmful substances, clean the territory of waste, make it possible to produce cheap electricity. The octane number of such a generator gas is 110-140, which is much higher than that of liquid fuel. This generator is adapted to any type of fossil fuel.

The efficiency of the gas generator is much higher than that of gas power plants. To provide the car with fuel, it is also more efficient to use a hydrogen or wood gas generator, then the amount of fuel equal to 1 liter of gasoline, depending on the price of raw materials, will cost 4-12 cents.

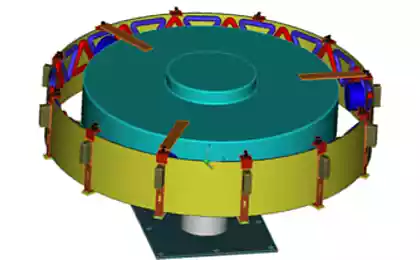

Structure of gas generator

Bunker Filter "Cyclone" Fine cleaning Filter Filter Pipeline Filter Coarse cleaning + Cooler gas mixer with air The principle of operation of the gas generator The formation of generator gas occurs with limited air access as a result of incomplete combustion of solid fuel. The interior space of working gas generators is divided into four zones: cushion;

The upper part of the bunker, which maintains a temperature of 150-200 C.

- dry distillation;

The middle part of the bunker, in which the temperature is 300-500 C. There is no air access, so the fuel is charred, acids, resins and other distillation products are released.

- combustion;

Located in the furm belt. In this zone at a temperature of 1100-1300 C is formed from dry distillation products and charred fuel CO.

- recovery.

It is located between the grate and the burning zone. Here, CO2 passes through the hot coal, connects to carbon particles. As a result, carbon monoxide is formed.

From a mixture of carbon monoxide, methane, hydrogen, alcohols SNZON, C2N5ON, etc. in the active chamber, the formation of a generator gas occurs. In cooling filters, it acquires ambient temperature and undergoes cleaning from suspended particles (dust, ash, acetic and formic acids).

Source: greenvolt.ru/

A gas generator is a device that converts solid or liquid fuel into a gaseous form.

In its active part, three areas flow into each other: thermal decomposition of fuel, oxidation, recovery.

The gas generator process is of three types:

- straight;

It differs in simplicity of execution. As a disadvantage - a large content of resins and moisture, which is eliminated with the help of purified fuel (coke, charcoal). - converted;

It contains a minimum content of resins, since the fuel almost completely decomposes, passing the high-temperature zone of "oxidation". - horizontal;

It's a pretty simple design. Part of the decomposition gas does not completely decompose, passing through the recovery zone. Therefore, the amount of resins is moderate.

All devices differ in the system of ash selection and fuel loading. The continuous process is the most technological. Video of the gas generator

Gas generator, working on waste, is sealed. This is confirmed by the fact that the exhaust gases of the engine using generator gas are more environmentally friendly. This cannot be said about the diesel generator. Motor life of engines that run on generator gas, much more than engines running on diesel fuel or gasoline.

In winter conditions, the gas generator on firewood performs more efficient work due to better filling of the engine cylinders with a working gas mixture. In stationary conditions, you can dispose of the heat generated by the generator, for example, for heating rooms.

Gas generators on solid fuel reduce the emission of harmful substances, clean the territory of waste, make it possible to produce cheap electricity. The octane number of such a generator gas is 110-140, which is much higher than that of liquid fuel. This generator is adapted to any type of fossil fuel.

The efficiency of the gas generator is much higher than that of gas power plants. To provide the car with fuel, it is also more efficient to use a hydrogen or wood gas generator, then the amount of fuel equal to 1 liter of gasoline, depending on the price of raw materials, will cost 4-12 cents.

Structure of gas generator

Bunker Filter "Cyclone" Fine cleaning Filter Filter Pipeline Filter Coarse cleaning + Cooler gas mixer with air The principle of operation of the gas generator The formation of generator gas occurs with limited air access as a result of incomplete combustion of solid fuel. The interior space of working gas generators is divided into four zones: cushion;

The upper part of the bunker, which maintains a temperature of 150-200 C.

- dry distillation;

The middle part of the bunker, in which the temperature is 300-500 C. There is no air access, so the fuel is charred, acids, resins and other distillation products are released.

- combustion;

Located in the furm belt. In this zone at a temperature of 1100-1300 C is formed from dry distillation products and charred fuel CO.

- recovery.

It is located between the grate and the burning zone. Here, CO2 passes through the hot coal, connects to carbon particles. As a result, carbon monoxide is formed.

From a mixture of carbon monoxide, methane, hydrogen, alcohols SNZON, C2N5ON, etc. in the active chamber, the formation of a generator gas occurs. In cooling filters, it acquires ambient temperature and undergoes cleaning from suspended particles (dust, ash, acetic and formic acids).

Source: greenvolt.ru/

Non-traditional gaming venues are becoming increasingly popular in Europe

Phenological calendar of events for the protection of strawberry