145

New nanostructured catalyst improves CO2 conversion to methanol + video

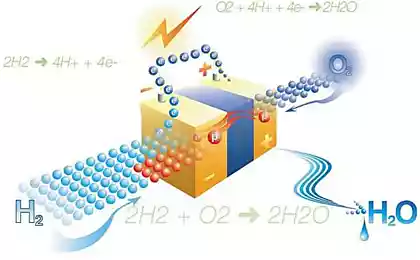

Scientists at the U.S. Department of Energy’s Brookhaven National Laboratory recently announced the discovery of a new catalytic system to convert carbon dioxide (CO2) into methanol, which is used to create a wide range of industrial chemicals and fuels. The new system not only has greater conversion efficiency than other commercial catalysts currently in use, but is also capable of involving a much larger amount of carbon dioxide, which is normally inert to participate in such chemical reactions.

The study, conducted by scientists at Brookhaven National Laboratory, included not only practical methods, such as testing the new system on site in real-world conditions, but also numerical simulations, which were conducted at the supercomputer center of the Universities of Seville and Barcelona, and which helped to compile a molecular description of the mechanism of methanol synthesis.

The researchers focused on studying a catalyst consisting of copper and cerium oxide nanoparticles mixed with titanium dioxide molecules. In previous studies, such metal oxide nanostructured catalysts have demonstrated their exceptional reactivity, but only under certain conditions.

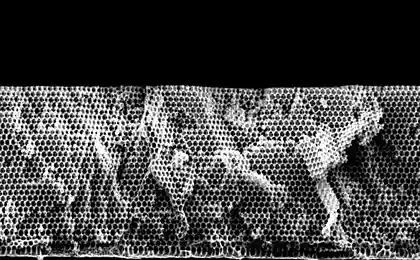

To study the reactivity of catalytic systems with double nanoparticles in converting carbon dioxide into methanol, the scientists used spectroscopy techniques. It allowed us to study the interaction of CO2 separately with ordinary copper, ordinary cerium oxide and the combination of copper with cerium oxide over a wide range of temperatures and pressures. According to the results of the study, the metallic component of the catalyst itself is not effective in the chemical reaction of methanol production. Binding and activation of carbon dioxide occurs precisely in the zone of interaction of metal nanoparticles and cerium oxide. Adjustment of this zone will allow achieving maximum efficiency of the methanol production process.

Source: www.cheburek.net

The study, conducted by scientists at Brookhaven National Laboratory, included not only practical methods, such as testing the new system on site in real-world conditions, but also numerical simulations, which were conducted at the supercomputer center of the Universities of Seville and Barcelona, and which helped to compile a molecular description of the mechanism of methanol synthesis.

The researchers focused on studying a catalyst consisting of copper and cerium oxide nanoparticles mixed with titanium dioxide molecules. In previous studies, such metal oxide nanostructured catalysts have demonstrated their exceptional reactivity, but only under certain conditions.

To study the reactivity of catalytic systems with double nanoparticles in converting carbon dioxide into methanol, the scientists used spectroscopy techniques. It allowed us to study the interaction of CO2 separately with ordinary copper, ordinary cerium oxide and the combination of copper with cerium oxide over a wide range of temperatures and pressures. According to the results of the study, the metallic component of the catalyst itself is not effective in the chemical reaction of methanol production. Binding and activation of carbon dioxide occurs precisely in the zone of interaction of metal nanoparticles and cerium oxide. Adjustment of this zone will allow achieving maximum efficiency of the methanol production process.

Source: www.cheburek.net

Japanese cars will ride on hydrogen from Russia

FreeWavz wireless headphones capable of tracking physical activity +video