443

Self-adhesive solar panels

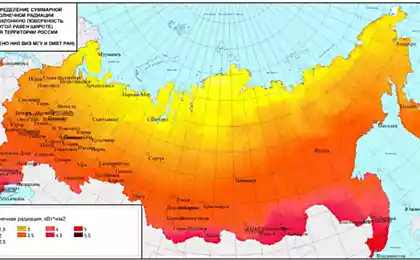

"In China, the rooftops of many buildings are equipped with devices for solar energy conversion," says Xiaolin Zheng (Xiaolin Zheng), which is working on a new type of solar panels. "Once my father noticed how cool it used to use Windows, walls, the entire surface of the buildings for solar energy, not just the roof."

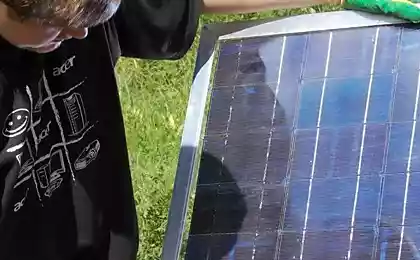

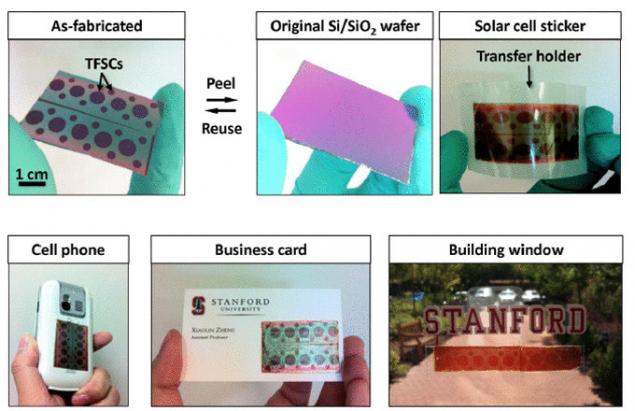

The invention, which is a research group Zheng at Stanford University, ever, is quite likely to make it possible. They created thin, flexible and adhesive solar panel – a solar sticker, adhesive label, which, in theory, will be able to power everything from buildings to airplanes.

"Making solar panel is extremely thin and flexible, we get the opportunity to use it in different ways," says Zheng, an associate Professor at Stanford University, and winner of the award of the President of the United States in the field of science and engineering for young experts. "I hope our discovery can dramatically increase the accessibility, ease and widespread use of solar energy."

In 2010, after hearing the words of his father, Zheng read research work, which again brought her back to this idea. The work described an experiment in which the nanomaterial graphene was grown on the Nickel layer located on a silicon wafer. When immersed in water, the Nickel separated from the surface, along with graphene.

"It sounded unbelievable," she recalls. "What if the same principle can be used to get more thin and flexible solar panel that can be removed to glue and it will stick on any surface?".

Conventional thin-film solar cells are manufactured on glass or silicon wafers, so they are hard, heavy and very limited in the place of use. Plastic or paper will make the solar panel more flexible but not resistant to high temperatures and chemicals needed for manufacturing.

"Our new technique allows us to consider the solar panel as a pizza," explains Zheng. "When you bake pizza, you use metal utensils, which can withstand high temperature. But in order to distribute the pizza economically, the seller uses a paper box."

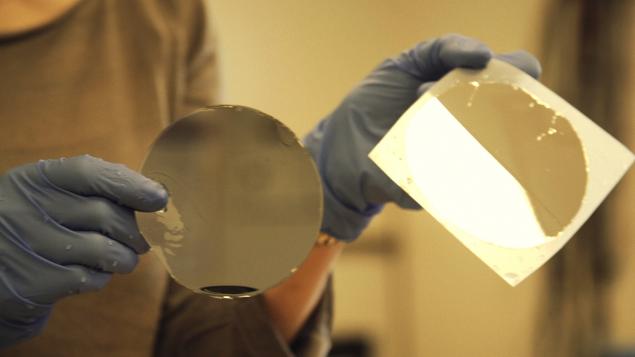

Working with his team, Zheng is how you would typically use silicone or glass surface for the manufacture of solar panels, but it is additionally inserted layer between the panel and the surface. After a few trial and errors, scientists have finally been able to separate the metal layer from the surface after soaking the entire structure in water for a few seconds.

The result was that the active solar panel, the thickness of which is only a few microns — about one-tenth the thickness of plastic film. "The material is very flexible, so it can be affixed to any surface – mobile phone, glass roof, wall or curved column."

Thin and flexible panels can produce the same amount of electricity as rigid, in addition they offer additional economic advantages, since it can significantly reduce production costs and, consequently, have a lower cost.

In traditional manufacturing, the solar cells price the base layer is 25% of the cost. The new method will replace the base layer of cheaper or already existing. For example, the Windows of the building themselves provide a base layer, so all that is needed is a photosensitive part. A solar cell, which can be easily removed and installed, allows you to save.

"Silicon wafer after a clean and shiny", says the scientist. "As well as a pizza pan, they can be used again and again, which translates to savings funds. And for the reason that adhesive solar panel much easier to install than conventional panels, this process will be easier and cheaper."

In a further study, Zheng plans to test the technology on more efficient solar cells than those used initially.

Source: facepla.net