158

Solar panels turned into colored windows

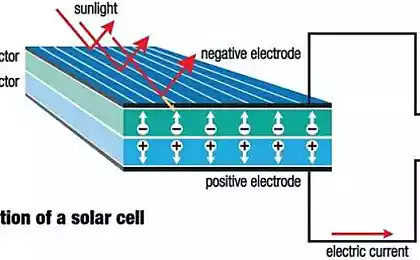

Beautiful stained glass, which is able to generate electricity, to part with their blood for the sake of such a miracle of technology will wish many eco-conscious homeowners who refuse to install on the roofs of their homes conventional solar panels for aesthetic reasons. Researchers from the University of Michigan (USA) have created a technology that allows the mass production of durable semi-transparent and at the same time colored solar panels using a hybrid silicon-organic composite.

In fairness, it is worth noting that several technologies for the production of colored solar cells existed before, but they all had a number of significant drawbacks: the dyes used blurred the outlines of objects, while special filters necessary to achieve acceptable efficiency distorted colors when changing the angle of view. Americans have managed to solve these problems by introducing several innovations at once.

First, to achieve the effect of transparency and improve clarity, they used an ultrathin layer of semiconductor (10-20 nm): instead of standard crystalline silicon, a layer of amorphous silicon (a-Si) was used. This material is actively used in the manufacturer of LCD displays, so engineers only had to adapt existing technologies to apply arrays a-Si on large flat surfaces.

Secondly, to create the desired color, the research team used the same amorphous silicon instead of conventional dyes. By applying material of different thicknesses, they obtained different colors: 6 nm for blue, 11 nm for green and 31 nm for red.

P.S. And remember, just changing our consumption – together we change the world!

Source: www.ekopower.ru/? p=2605

In fairness, it is worth noting that several technologies for the production of colored solar cells existed before, but they all had a number of significant drawbacks: the dyes used blurred the outlines of objects, while special filters necessary to achieve acceptable efficiency distorted colors when changing the angle of view. Americans have managed to solve these problems by introducing several innovations at once.

First, to achieve the effect of transparency and improve clarity, they used an ultrathin layer of semiconductor (10-20 nm): instead of standard crystalline silicon, a layer of amorphous silicon (a-Si) was used. This material is actively used in the manufacturer of LCD displays, so engineers only had to adapt existing technologies to apply arrays a-Si on large flat surfaces.

Secondly, to create the desired color, the research team used the same amorphous silicon instead of conventional dyes. By applying material of different thicknesses, they obtained different colors: 6 nm for blue, 11 nm for green and 31 nm for red.

P.S. And remember, just changing our consumption – together we change the world!

Source: www.ekopower.ru/? p=2605