596

New technology to increase the efficiency of solar panels

Scientists at Stanford University found an innovative way of applying the electrical wiring on the surface of the solar cell, which is invisible to transmitted light. Solar cells made using this technology can significantly increase the efficiency of solar cells. Traditional solar cells are a semiconductor that converts solar energy into electricity, which is located between two metal contacts conducting electrical current. But this structure has one drawback: shiny metal reflects sunlight, which reduces the efficiency of the device.

Researchers from Stanford have developed a technology with which you can "hide" the reflective material to direct the light directly underneath the semiconductor (usually silicon). Their discovery, published in the journal ACS Nano, could radically change the design and method of manufacturing solar cells.

"Using nanotechnology, we have developed a new method of manufacturing a metal upper layer, which almost completely transmits the light of the sun, says the leading author of the project Vijay Narasimhan. Our technology can significantly increase productivity and reduce the cost of solar panels". Conventional solar panels, which are often found on the roofs of the houses have on their surface a plaid pattern. Lines that we see are actually metal contacts. The more contacts, the more light is "lost" and, accordingly, the impact on the energy efficiency of the element.

The top layer of the conductive contacts is relatively few – 5 — 10%. However, this means that 5-10% of solar energy that could be used to generate electricity — just reflected.

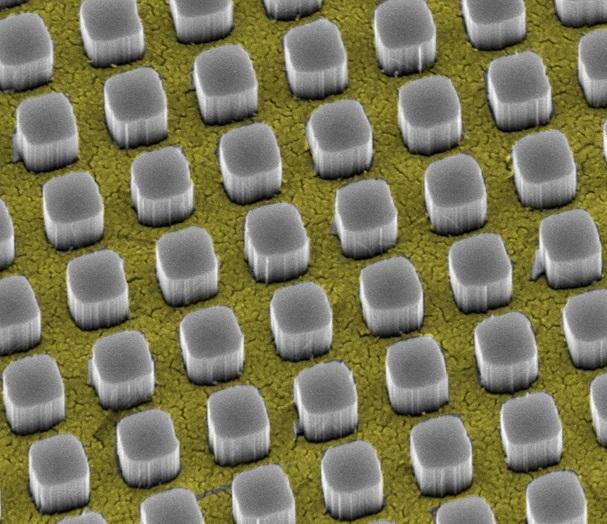

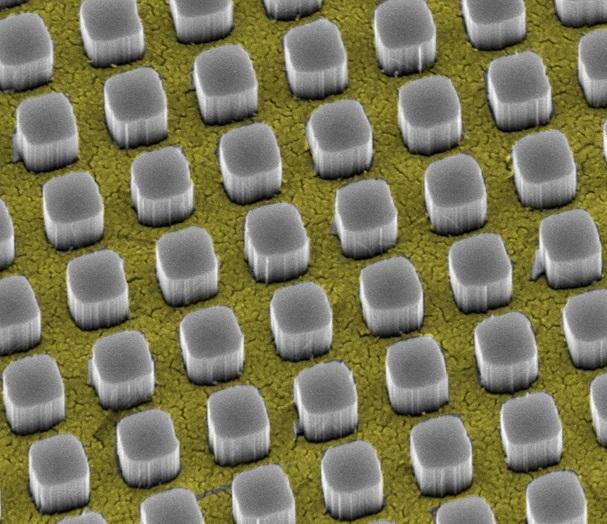

In their study, the researchers placed the most thin gold film (thickness of 16 nanometers) on a flat silicon surface. Film-the conductor consists of many nanoscale rectangular hole, however to the human eye they are invisible – gold film seems perfectly smooth like a mirror.

Optical analysis showed that the perforated gold film covers 65% of the surface of the silicon and, on average, reflects about 50% of incident light. Scientists have concluded that if you find a way to hide the conductive film, on a silicon semiconductor solar light will do more.

The solution was the creation of the silicon column size is only 300 nm which rise above a gold film and redirect the sun's light before it reaches the metal surface. To obtain such a structure managed by a chemical process.

Silicon nanostate rise above the surface of the gold film and the redirected sunlight

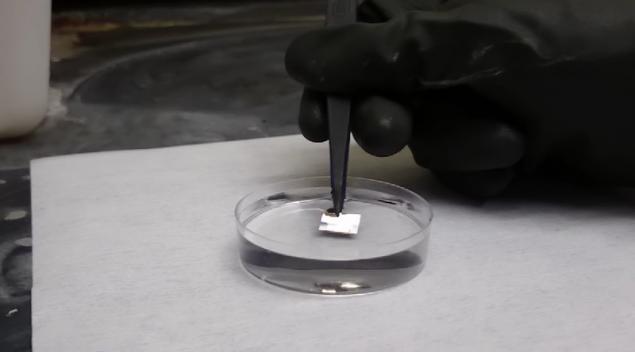

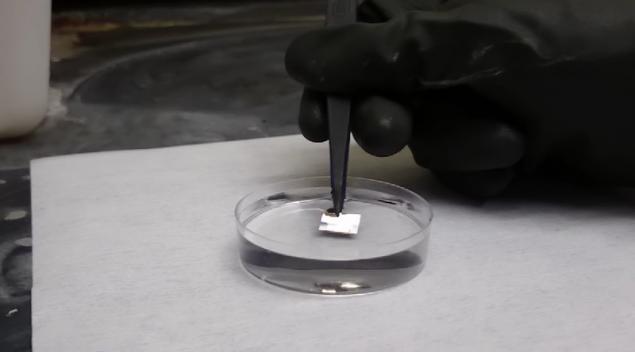

Scientists immersed the silicon wafer along a gold film on the surface in a solution of hydrogen peroxide and hydrofluoric acid. The metal was instantly immersed in the substrate and in the place of holes formed nanostate silicon. However, the shiny gold surface changed its color to dark red – evidence that gold has ceased to reflect light.

"When you turn on the faucet [aerator], not all the water passes through the grating, explains Narasimhan. But if each hole in the lattice to provide a small funnel – most of the water will pass through them without any problems. That and running our structure: nanostate act as funnels that capture light and send it on the silicon surface through the holes in the metal lattice". According to the authors of the study, in addition to gold, the proposed method can also be used for contacts of platinum, silver, Nickel and other metals.

It is expected that the new technology will increase the efficiency of traditional solar panels from 20% to 22% — a significant growth in such systems. In addition, this method can be used not only for creating efficient solar cells but also for production of various photosensors, LEDs and a transparent battery. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: ecotechnica.com.ua/energy/solntse/534-nevidimyj-provod-uluchshit-effektivnost-solnechnykh-batarej.html

Researchers from Stanford have developed a technology with which you can "hide" the reflective material to direct the light directly underneath the semiconductor (usually silicon). Their discovery, published in the journal ACS Nano, could radically change the design and method of manufacturing solar cells.

"Using nanotechnology, we have developed a new method of manufacturing a metal upper layer, which almost completely transmits the light of the sun, says the leading author of the project Vijay Narasimhan. Our technology can significantly increase productivity and reduce the cost of solar panels". Conventional solar panels, which are often found on the roofs of the houses have on their surface a plaid pattern. Lines that we see are actually metal contacts. The more contacts, the more light is "lost" and, accordingly, the impact on the energy efficiency of the element.

The top layer of the conductive contacts is relatively few – 5 — 10%. However, this means that 5-10% of solar energy that could be used to generate electricity — just reflected.

In their study, the researchers placed the most thin gold film (thickness of 16 nanometers) on a flat silicon surface. Film-the conductor consists of many nanoscale rectangular hole, however to the human eye they are invisible – gold film seems perfectly smooth like a mirror.

Optical analysis showed that the perforated gold film covers 65% of the surface of the silicon and, on average, reflects about 50% of incident light. Scientists have concluded that if you find a way to hide the conductive film, on a silicon semiconductor solar light will do more.

The solution was the creation of the silicon column size is only 300 nm which rise above a gold film and redirect the sun's light before it reaches the metal surface. To obtain such a structure managed by a chemical process.

Silicon nanostate rise above the surface of the gold film and the redirected sunlight

Scientists immersed the silicon wafer along a gold film on the surface in a solution of hydrogen peroxide and hydrofluoric acid. The metal was instantly immersed in the substrate and in the place of holes formed nanostate silicon. However, the shiny gold surface changed its color to dark red – evidence that gold has ceased to reflect light.

"When you turn on the faucet [aerator], not all the water passes through the grating, explains Narasimhan. But if each hole in the lattice to provide a small funnel – most of the water will pass through them without any problems. That and running our structure: nanostate act as funnels that capture light and send it on the silicon surface through the holes in the metal lattice". According to the authors of the study, in addition to gold, the proposed method can also be used for contacts of platinum, silver, Nickel and other metals.

It is expected that the new technology will increase the efficiency of traditional solar panels from 20% to 22% — a significant growth in such systems. In addition, this method can be used not only for creating efficient solar cells but also for production of various photosensors, LEDs and a transparent battery. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: ecotechnica.com.ua/energy/solntse/534-nevidimyj-provod-uluchshit-effektivnost-solnechnykh-batarej.html