2086

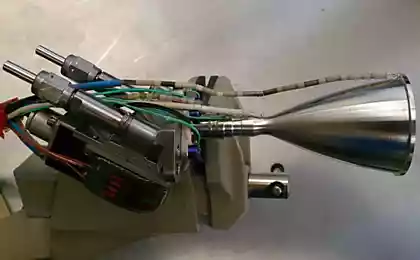

The first jet printed on 3D-printer

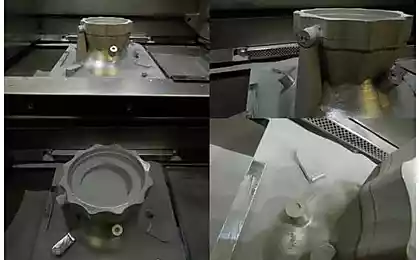

While NASA is experimenting with 3D-printing nozzle head and other parts for spacecraft engineers from Monash University (Australia), printed and assembled a real jet engine . More precisely, even two identical copies of the two exhibitions.

This is a fully functioning small turbine, which even now is placed on the plane or motor boat. Or some homemade gadget like jetpacks to fly to the country.

As NASA engineers used the method of laser sintering. There used printer EOSINT M 280 .

Engine printed as proof that modern 3D-printers are suitable for use in the aerospace industry. In fact, NASA has proven it before. Their rocket injector during testing withstand temperatures of 3300 ° C, while its production cost is much cheaper than the welding of 163 parts on a standard project.

At Monash University have printed a copy of the gas turbine Microturbo (Safran) . This is a pretty old model, but it is still in operation as auxiliary power unit on the aircraft such as Falcon 20.

This engine is disassembled into parts, each part scanned 3D-scanner, and then printed in duplicate.

Of course, industrial printers such as 1, 2-ton EOSINT M 280 while pricey, but not far off the day in every city block will open workshops where inexpensive metal part will print to order. Unless the authorities intervened and banned ordinary citizens to use this technology. Unfortunately, this is quite likely.

Source: geektimes.ru/post/246456/

Found the brightest and most distant remote from bright quasars

As I have implanted RFID in his arm, and then another NFC. Part 1