583

How to actually collect APC

Few people know, but the build process BTR - is an art in which the amazing shapes beautifully combined with frightening power and stunning craftsmanship. I do not know about you, but I was really impressed. Read on and look at the real beauty of the art of war.

Naked body, factory workers say, "gondola", come from Vyksa not very intelligent. Already cooked, colored and part of the wiring and the mechanization of the suspension.

Shinmontazh. Tensioning the tire on the disc, there is a manual.

Further, a body with bolted wheels, stand up to the assembly line.

Inside the case lay mains and install the unit.

The conveyor. No automation. No robots. All handles. There are no overhead power lines, and thus the pneumatic tools. The only thing I saw - impact wrench to loosen the wheel nuts. Yes, and one electric, the heaviest. However, for all operations and parts, conducted strict control. Maybe that's why, the percentage of complaints is extremely low.

BTR - completely isolated hydro and gas. In the photo the door with a gas analyzer.

Set all the pieces. Enterprise military, so for the Snapshot was conducted very strict control.

The conveyor. Machines do not go under them moves the tape to the legs.

Motor and Gearbox KAMAZ, on the motor two turbines blowing in different sections. The mechanical pump. Without EURO.

Machines with mounted power plants.

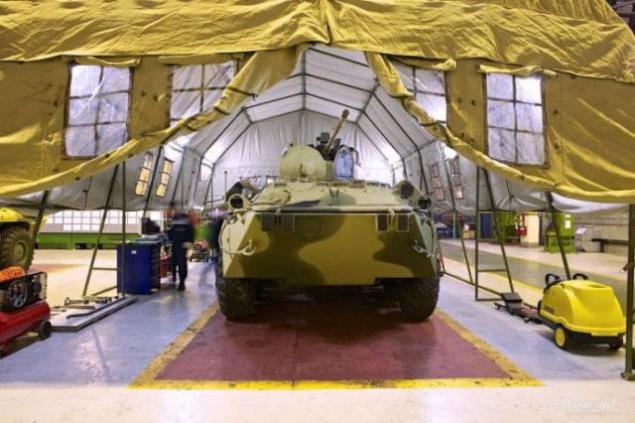

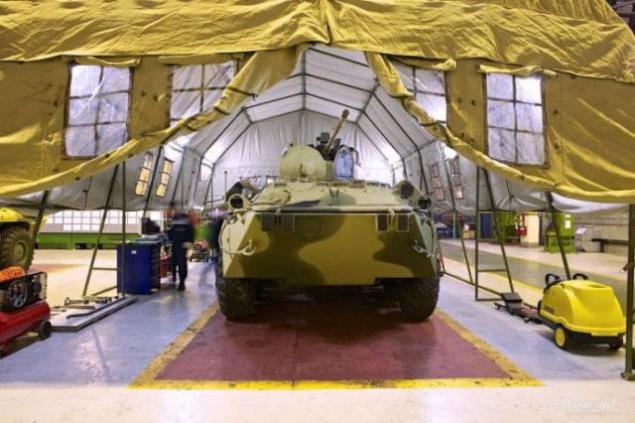

Shop debugging and adjustment.

Then go to the installation of the machine that is ordered. Discussed even within the cladding material (Rolls-Royce has a rest). Generally, APCs, and so full of modifications: floating and floating machine communication, command and staff vehicle (instead of the tower, to make a "hump" on the landing bay) and much more, which will order the client. There is even a pickup truck.

In this shop, all products are moved under its own power. The main thing to be careful, may flatten.

Various modifications of cars.

All cars are waiting trial march, is 100 kilometers from the factory driver, and then another 50 km - with the customer. And only then, if anything has fallen off or broken, products are shipped to the customer.

Pool. Part of the test of the march.

And it floats! Do not speed boat, of course. But not "Titanic." Floats. Floats and even roll in turns, like a ship.

Out of the water. It looks spectacular.

After the march, the product driven on public acceptance. Check everything. Literally.

Immersed in a minibus waiting for us, we moved towards the site. There also went for a swim APC. The landfill is located on the territory of the plant. Not big in size. A standard set of obstacles that standard, and "cool" passes under test technique. What actually happened.

Naked body, factory workers say, "gondola", come from Vyksa not very intelligent. Already cooked, colored and part of the wiring and the mechanization of the suspension.

Shinmontazh. Tensioning the tire on the disc, there is a manual.

Further, a body with bolted wheels, stand up to the assembly line.

Inside the case lay mains and install the unit.

The conveyor. No automation. No robots. All handles. There are no overhead power lines, and thus the pneumatic tools. The only thing I saw - impact wrench to loosen the wheel nuts. Yes, and one electric, the heaviest. However, for all operations and parts, conducted strict control. Maybe that's why, the percentage of complaints is extremely low.

BTR - completely isolated hydro and gas. In the photo the door with a gas analyzer.

Set all the pieces. Enterprise military, so for the Snapshot was conducted very strict control.

The conveyor. Machines do not go under them moves the tape to the legs.

Motor and Gearbox KAMAZ, on the motor two turbines blowing in different sections. The mechanical pump. Without EURO.

Machines with mounted power plants.

Shop debugging and adjustment.

Then go to the installation of the machine that is ordered. Discussed even within the cladding material (Rolls-Royce has a rest). Generally, APCs, and so full of modifications: floating and floating machine communication, command and staff vehicle (instead of the tower, to make a "hump" on the landing bay) and much more, which will order the client. There is even a pickup truck.

In this shop, all products are moved under its own power. The main thing to be careful, may flatten.

Various modifications of cars.

All cars are waiting trial march, is 100 kilometers from the factory driver, and then another 50 km - with the customer. And only then, if anything has fallen off or broken, products are shipped to the customer.

Pool. Part of the test of the march.

And it floats! Do not speed boat, of course. But not "Titanic." Floats. Floats and even roll in turns, like a ship.

Out of the water. It looks spectacular.

After the march, the product driven on public acceptance. Check everything. Literally.

Immersed in a minibus waiting for us, we moved towards the site. There also went for a swim APC. The landfill is located on the territory of the plant. Not big in size. A standard set of obstacles that standard, and "cool" passes under test technique. What actually happened.