586

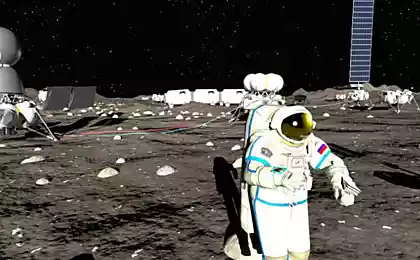

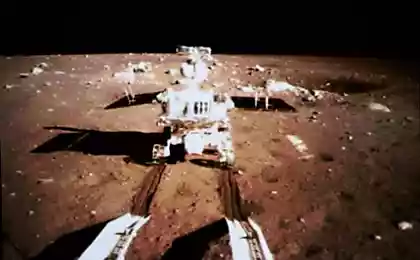

Makhno on the moon?

Professor of robotics at Carnegie hopes to build a spacecraft that can carry on the moon one of his robots.

10 photos via dailymail.co.uk

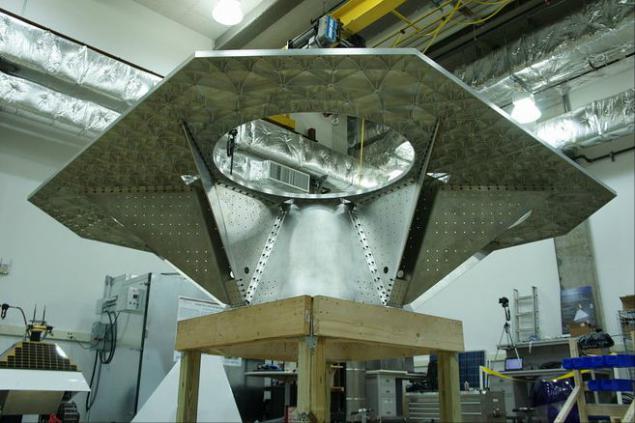

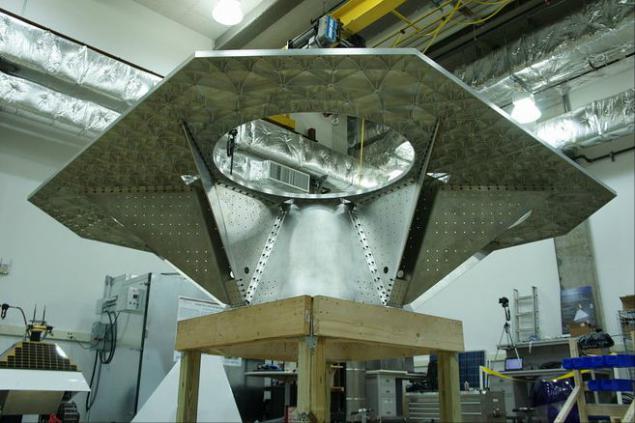

1. Lunar lander assembled and disassembled several times, performing a full scan. Details fastened using temporary fasteners Klek, which are then replaced by a permanent locks capable of withstanding the temperature drop and congestion.

2. Laboratory planetary robotics at Carnegie - the place where the assembly of the space ship. In the foreground - a space ship in the process of assembly. In the background - a model of a space ship.

3. The students are involved in the assembly of the vessel. Prior to assembly all parts are thoroughly sweep. Students conduct surface treatment with an alcohol.

4. Area of fuel tanks (large holes) and the main engine (smaller aperture). The weight of the finished platform will be two thousand pounds.

5. Build a space ship. In order to secure the parts used about 1,000 clips.

6. Check with the help of dummy fuel tank.

7. The students are involved in the assembly of the vessel.

8. The design is ready to be shipped.

9. The developer unit, twenty-four Kalayaro Jason, watching the loading of a module in the truck.

10. Lunar lander assembled. Balls of foil used as dummy fuel tank.

Source: http: //

10 photos via dailymail.co.uk

1. Lunar lander assembled and disassembled several times, performing a full scan. Details fastened using temporary fasteners Klek, which are then replaced by a permanent locks capable of withstanding the temperature drop and congestion.

2. Laboratory planetary robotics at Carnegie - the place where the assembly of the space ship. In the foreground - a space ship in the process of assembly. In the background - a model of a space ship.

3. The students are involved in the assembly of the vessel. Prior to assembly all parts are thoroughly sweep. Students conduct surface treatment with an alcohol.

4. Area of fuel tanks (large holes) and the main engine (smaller aperture). The weight of the finished platform will be two thousand pounds.

5. Build a space ship. In order to secure the parts used about 1,000 clips.

6. Check with the help of dummy fuel tank.

7. The students are involved in the assembly of the vessel.

8. The design is ready to be shipped.

9. The developer unit, twenty-four Kalayaro Jason, watching the loading of a module in the truck.

10. Lunar lander assembled. Balls of foil used as dummy fuel tank.

Source: http: //