690

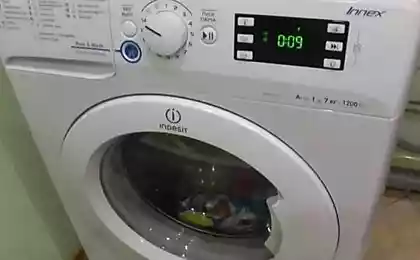

8-year-old washing machine

Patient: 8-year-old washing machine

Diagnosis: A clogged water pipe

Tools: Phillips screwdriver - 1 pc., Sponge - 1 pc., Toothbrush b \ y - 1 pc., Clamp - 1 pc.

Start of operation: 11:28, Wednesday, September 7, 2011

Remove the lid, the front panel and in fact everything that impedes access to the necessary pipes.

Remove the tray powder and disconnect it from all the adjacent tubes, which counted 3 pieces.

That's actually the culprit fault - rubber tube connecting the tray powder and a drum machine directly. From the drum, it gets quite easy and uncomplicated as then connected to it. But to the tray for powder prisobachit pretty tough collar, but with this we will face in the assembly.

Handles well washed out the interior of the tube

[

The contents of the tube (of course, large parts do not count :))

This is after a certain stage of cleaning

Soak all parts for years been exposed salts, lime and surfactant powder in warm water with vinegar

This tube supply water to the water stiralki

Even galvanized metal is not a cure time, water and powder:

Insert the tube into the cleaned drum and attach the clamp back to the tray for powder Native clamp set back did not happen))), which is the same thing the essence rather than the form:

We connect the rest of the tube in its place, it is difficult to mix them as they are all different sizes. Set the tray back to their slots, fasten. Return the cable to the relay distribution stream in the tray into place.

Panel home

Close the lid and a satisfied exhale

Posted in [mergetime] 1315461171 [/ mergetime]

Results:

There were unscrewed \ twisted screws 7.

End of operation: 12:30 PM, Wednesday, September 7, 2011

The result of the operation: Return to the operation indispensable thing in the economy.

Launched laundry, rustled like new and "whistling"!

Source:

Diagnosis: A clogged water pipe

Tools: Phillips screwdriver - 1 pc., Sponge - 1 pc., Toothbrush b \ y - 1 pc., Clamp - 1 pc.

Start of operation: 11:28, Wednesday, September 7, 2011

Remove the lid, the front panel and in fact everything that impedes access to the necessary pipes.

Remove the tray powder and disconnect it from all the adjacent tubes, which counted 3 pieces.

That's actually the culprit fault - rubber tube connecting the tray powder and a drum machine directly. From the drum, it gets quite easy and uncomplicated as then connected to it. But to the tray for powder prisobachit pretty tough collar, but with this we will face in the assembly.

Handles well washed out the interior of the tube

[

The contents of the tube (of course, large parts do not count :))

This is after a certain stage of cleaning

Soak all parts for years been exposed salts, lime and surfactant powder in warm water with vinegar

This tube supply water to the water stiralki

Even galvanized metal is not a cure time, water and powder:

Insert the tube into the cleaned drum and attach the clamp back to the tray for powder Native clamp set back did not happen))), which is the same thing the essence rather than the form:

We connect the rest of the tube in its place, it is difficult to mix them as they are all different sizes. Set the tray back to their slots, fasten. Return the cable to the relay distribution stream in the tray into place.

Panel home

Close the lid and a satisfied exhale

Posted in [mergetime] 1315461171 [/ mergetime]

Results:

There were unscrewed \ twisted screws 7.

End of operation: 12:30 PM, Wednesday, September 7, 2011

The result of the operation: Return to the operation indispensable thing in the economy.

Launched laundry, rustled like new and "whistling"!

Source: