767

Morion or how we "wild boar" cut

As promised in the theme of the Year 2011 The latest collection, will describe the main stages of the manufacture of stone bowl on a stand.

In this example, the ball is made of a huge crystal morion from Volyn.

Again a lot of pictures, let you know how to finish

Let's start

Head 1st.

Initially, it was:

Axe, naturally more useful

-

2nd Chapter.

How to turn this "wild boar" in the balloon?

First, it should be carefully considered. And choose a place from which will actually make the ball.

Just, just,

two,

Three!

Chapter third.

Next -REZAT!

For this we need:

most big "Bulgarian»

and diamond blade for cutting stone

Putting "Bulgarian" with the disc, and forward - cut off everything that does not fit into a cube.

such is ...

... And it

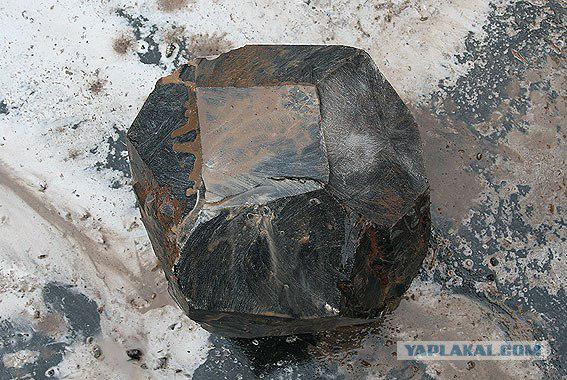

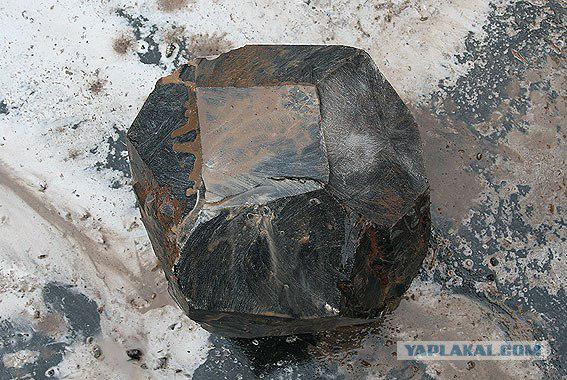

and so until then, until you get something resembling a "cube»

Now cutting corners until you get something like this:

Healthy, damn it, we got!

Now - a little break

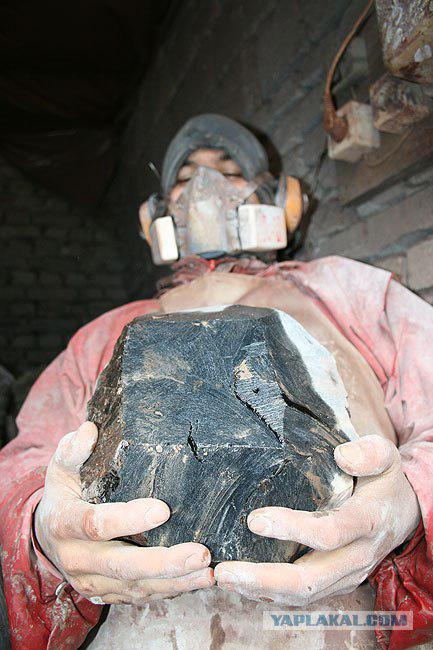

And my favorite - saw))

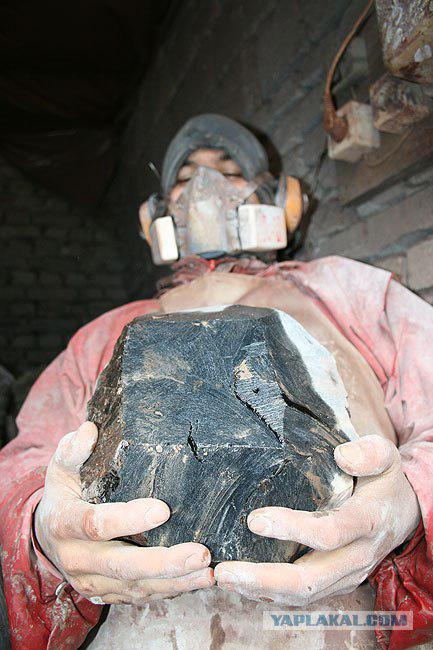

ps .: blank bigger than my head!

4th Chapter.

Further, our goal, consistently (though it is possible and chaotic, it's like someone like that) to cut all that distinguishes this piece from the ball.

To begin with, for example, all the angles.

like this,

so,

And so

It should get something like this

but not resting on our laurels, we continue to cut all unnecessary

and gradually become something like ...

REMEMBER !!! The better you will cut it - the easier it will be to grind on.

Chapter 5th

Therefore, we will continue:

Better

Better yet

almost good

Well

All good

No chapel perfection, but I do not get better

And besides, late evening

Posted in [mergetime] 1327145589 [/ mergetime]

EPILOGUE

But this is not the end, rather - is just the beginning. Now it is a long and tedious grind. After that - lapping and polishing.

P.S. The fact that it would cut my left one day.

Actually the most difficult and important is behind us, now long and careful process of its powders.

Let's start:

For this we need:

metal crown,

abrasive powder,

and harvesting of the ball.

We combine all this and for a long time on this spinning ball crown with powder ...

After some 10-15 hours (depends on the experience and stamina) you come to the final

fade out all gashes and chipped

But this stone ... there is always room for surprises ...

For example, this time put out a piece of crystal.

depth of 1, 5 - 2 mm.

It's only 6-8 hours of extra work)))

But there comes a time when it and behind.

Ball trate and can be measured.

We've got 185 mm instead of the original 195. Not the worst result!

Well, continue?

We continue using all sharpens finer abrasive

sharpen ball

and constantly seeking a uniform haze on the entire surface.

about how it should look

So far so good.

This means that it is time for the General fitting

Well into place, and how it looks to me like the whole

But before the end is still far.

To be handling all the finer abrasives

It's enough

Now polish !!!

if it turns out - then everything is done correctly

That's all. Bowl on stand ready !!!

The whole process took us:

Cut 1 day;

Vytachivanie 3 days;

Lapping 1 day;

Polishing and manufacture of stand 1 day.

TOTAL: 6 days of intensive work.

Such is the "Kabanchik»

And the photo with the carpet before delivery

Source:

In this example, the ball is made of a huge crystal morion from Volyn.

Again a lot of pictures, let you know how to finish

Let's start

Head 1st.

Initially, it was:

Axe, naturally more useful

-

2nd Chapter.

How to turn this "wild boar" in the balloon?

First, it should be carefully considered. And choose a place from which will actually make the ball.

Just, just,

two,

Three!

Chapter third.

Next -REZAT!

For this we need:

most big "Bulgarian»

and diamond blade for cutting stone

Putting "Bulgarian" with the disc, and forward - cut off everything that does not fit into a cube.

such is ...

... And it

and so until then, until you get something resembling a "cube»

Now cutting corners until you get something like this:

Healthy, damn it, we got!

Now - a little break

And my favorite - saw))

ps .: blank bigger than my head!

4th Chapter.

Further, our goal, consistently (though it is possible and chaotic, it's like someone like that) to cut all that distinguishes this piece from the ball.

To begin with, for example, all the angles.

like this,

so,

And so

It should get something like this

but not resting on our laurels, we continue to cut all unnecessary

and gradually become something like ...

REMEMBER !!! The better you will cut it - the easier it will be to grind on.

Chapter 5th

Therefore, we will continue:

Better

Better yet

almost good

Well

All good

No chapel perfection, but I do not get better

And besides, late evening

Posted in [mergetime] 1327145589 [/ mergetime]

EPILOGUE

But this is not the end, rather - is just the beginning. Now it is a long and tedious grind. After that - lapping and polishing.

P.S. The fact that it would cut my left one day.

Actually the most difficult and important is behind us, now long and careful process of its powders.

Let's start:

For this we need:

metal crown,

abrasive powder,

and harvesting of the ball.

We combine all this and for a long time on this spinning ball crown with powder ...

After some 10-15 hours (depends on the experience and stamina) you come to the final

fade out all gashes and chipped

But this stone ... there is always room for surprises ...

For example, this time put out a piece of crystal.

depth of 1, 5 - 2 mm.

It's only 6-8 hours of extra work)))

But there comes a time when it and behind.

Ball trate and can be measured.

We've got 185 mm instead of the original 195. Not the worst result!

Well, continue?

We continue using all sharpens finer abrasive

sharpen ball

and constantly seeking a uniform haze on the entire surface.

about how it should look

So far so good.

This means that it is time for the General fitting

Well into place, and how it looks to me like the whole

But before the end is still far.

To be handling all the finer abrasives

It's enough

Now polish !!!

if it turns out - then everything is done correctly

That's all. Bowl on stand ready !!!

The whole process took us:

Cut 1 day;

Vytachivanie 3 days;

Lapping 1 day;

Polishing and manufacture of stand 1 day.

TOTAL: 6 days of intensive work.

Such is the "Kabanchik»

And the photo with the carpet before delivery

Source: