931

Rivers of molten metal

Reporting from Zhlobin (Belarus), but rather with the largest steel plant in Belarus.

Will be 69 photos

Taken from here

BTW metallurgy holidays. Uraaa comrades!

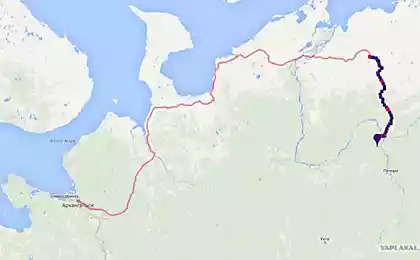

Austrians Italians erected Belarusian Steel Works even when a foreigner, we watched as a miracle. The decision to turn to the capitalist party contractors then looked very exotic. The contract on the construction was signed in 1982, even under Brezhnev, commercial operation officially started in the 85th. Then Zhlobin has focused the best of what there was in the world steel industry. Now BMZ is one of the major domestic exporters and taxpayers. Onliner.by visited one of the hottest, profitable and spectacular productions of the country.

BMZ is now the era of rampant modernization. Dust post: everywhere something to build, break, change. Even skrapovozy scrap sent to the detour: the roads are repaired on site, too.

These heavy machines on wheels made of cast rubber referred to here, of course, "centipedes". They deliver huge "basket" with shredded scrap to the furnace.

2.

Four

5.

The plant, which occupies a territory of about two hundred and fifty acres, operating more than twelve thousand people of Zhlobin and the neighboring settlements.

7.

In the Electric shop №1, where we're going, two ovens, one is working - №2. Shattered space temperature furnace casing №1 piled outside. The furnace was stopped a few days ago - upgrade, going to the October increase its capacity to one million tons of steel a year.

A total of three plant furnace (considering stopped). In general, the company is now the main task - to get to 3 million tons of steel a year. Moreover, BMZ does not want to sell billets, semi-finished products, but more on that below ... Around it all and turns: the radical replacement of equipment, construction of huge plants and the creation of new industries. And it is important to upgrade without stopping production.

At the plant it is necessary to constantly turn my head, listen to the signals to not crept back "centipede", and on top - the crane with a hundred tons of liquid steel. "Danger Zone", it seems, is the most popular label.

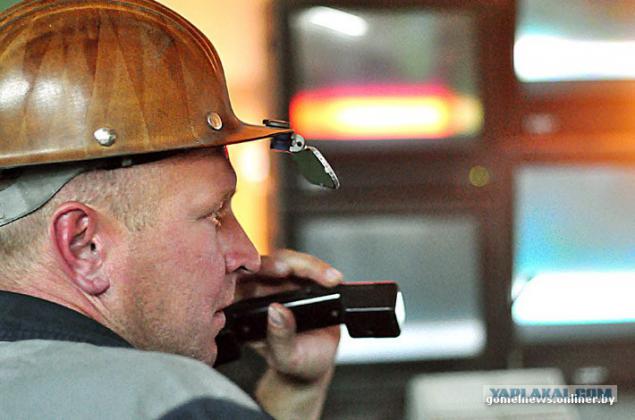

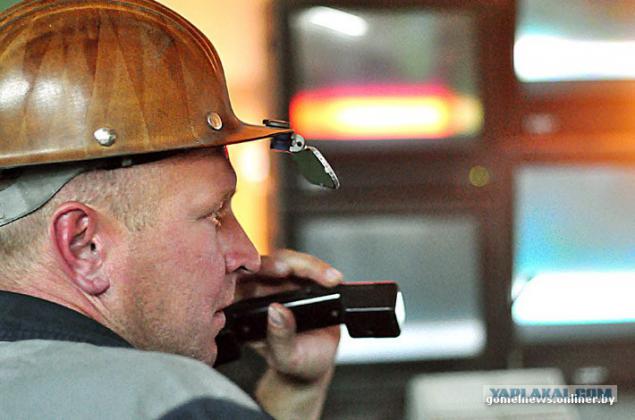

The shift meltshop Oleg Pryadko the example of the dismantled furnace №1 simplified describes her device.

Bottom - "hearth" with gutters for discharging metal and slag, above it - the actual body, above - the frame and lid with openings for the electrodes. Inside the container is lined with refractory materials. Outside - hideous hoses and pipes that were in the area unbearable heat. Through them under pressure of 6 atmospheres, is fed continuously to the housing cooling water. Otherwise, he would not survive.

12.

13.

Now the fun begins. Under siren crane delivers a basket with a crowbar. All this falls into the furnace.

16.

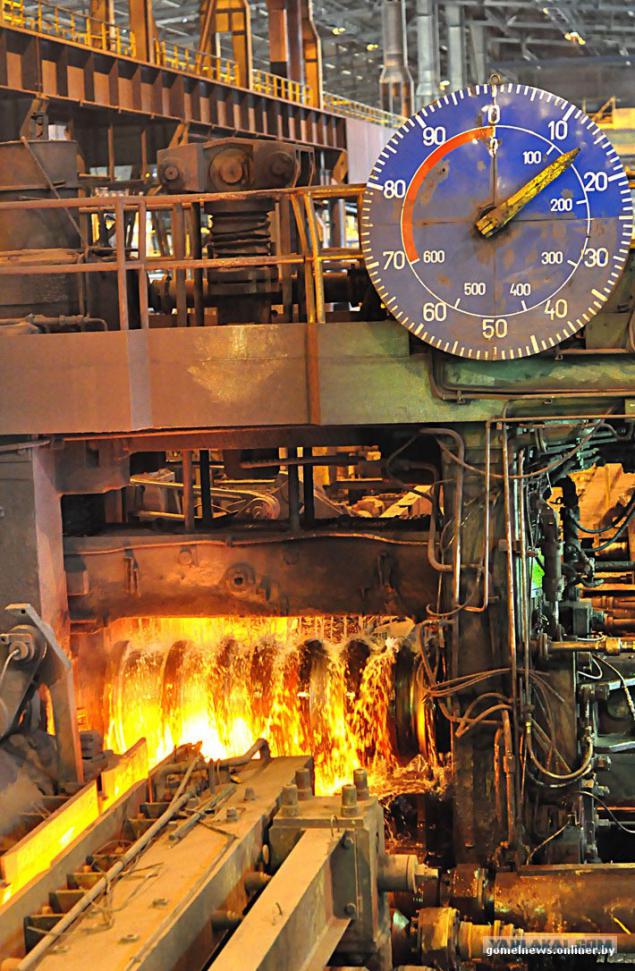

Top descend into the oven three powerful "pillars" - electrodes. It uses the simple principle of welding: electric arc melts the metal.

18.

19

20

21.

By the way, in the state of BMZ have pyrotechnics (read - engineers). The fact that scrap - not an easy thing. Especially one that is imported from Russia. In general, the military - a major supplier of iron ingots discharged something unusual at the factory are not. But sometimes the media gets the information about the next batch of ammunition found in the car. There are also some hand grenades and rifle and shots to the RPG and missiles. To all this does not work in the oven and need pyrotechnics.

Furnace capacity - 120 tons. Of these, 110 will merge the rest will flounder at the bottom - metallurgists call it "swamp." Pryadko explained swamp is necessary to maintain the oven in a heated state until next boot. And energy saving, and time.

The electrodes are made of pure graphite. In fact, the three multi-ton pencil leads length 2, 6 m and a diameter of 60 cm.

23

We watch the process from behind the glass control panel. On one of the monitors, among many obscure characters flit numbers - the number of kilowatt-hours consumed.

Oleg Pryadko said that in the one melting furnace burns 42,000 kVt.-hour of energy - can be a day to feed the city with a population of 80,000 (as of Zhlobin).

Heating is provided not only by the electric arc, but also due to the combustion injected into the carbon, oxygen and other components.

Controllers (joysticks) can be controlled from the control different processes. Including tilt the oven to "shake up" the contents for more uniform heat.

26

27

In the most extreme places are air-cooled camera, a picture with them and displayed on monitors. Actually, there is a particular dynamic to be seen - just the flames of hell. They say that if "dynamics" - then something went wrong.

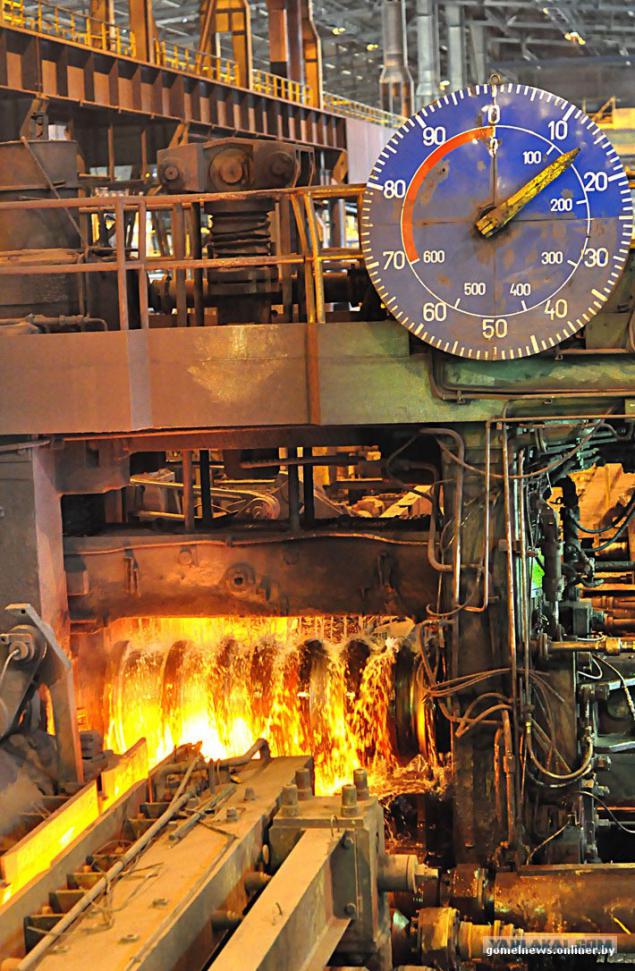

On the lookout more beautiful and much hotter. The liquid steel through the filter resembles a boiling soup with protein foam. Near long idle time - was hot. On the addition of alloying elements and other provisions of the melt additive technology responds beautiful waves of multicolored flame.

The melt temperature of about 1650 degrees. Since this figure to the uninitiated nothing says steelworkers of the Soviet Union, loving visibility lead invariable example: that if to throw a cat in a bucket, do not fly to the liquid metal evaporates along the way. Cats, of course, there's spawn was not found, but somehow believe in the word.

31

Melting takes about 50 minutes. After that, the metal fuses (do not forget to leave the "swamp"). The slag is separated - it will be sold to builders.

Before you get on steel casting machine, it must be "Dowar" in the ladle furnace to "slow fire" - about 1,550 degrees.

33

In the process of finishing the sample is taken. Also the whole affair. Operators loved old movies to shoot the epic steelworker who long ladle scooped in Martin sparkling mass. Now, there is no beauty that ... invented a special one-off tube of pressed paper. It is attached to a metal rod, is dipped into the metal, and then pull out, pull out quickly hardening "probe."

He also

In a similar way to measure the temperature of the melt - by connecting to an external indicator paper the tube, which is hidden from the thermocouple wires of platinum and rhenium.

Ready liquid enters the continuous casting machine №2. She, by the way, living out the last days of date. The shop has already cleared space for new equipment.

Near the refractory practiced with remote imposing. Instead, radio-controlled cars they tracked machine with a manipulator. At its end is mounted jackhammer. Learn a new technique: knock petrified protective lining (lining) from the bucket in front of repair.

36

37

38

39

By the way, about the refractory. This is one of the most heroic profession. Its essence is to prepare a huge bucket to fill in a metal. Generally, the liquid steel is easy to cut the metal walls. Probably every steel plant is a legend about how the day went bankrupt bucket. In such cases, a white jet of pressurized peel wherever falling. To avoid this, the inside scoop spread in several layers of refractory bricks and / or coated with special cement. After 60-65 heats all knock - and the new ...

There are 6 casting machine workers - the number of streams of liquid steel, which do not have the right to be interrupted. The slag from the surface of the liquid metal is removed manually with iron hooks. Soon this technology will go into oblivion.

BMZ

BMZ

BMZ

BMZ

BMZ

Beauty

where do without pets

BMZ

In the air, a strange smell, as if something in the pan burnt (and it is not blue). (As strange as it sounds for the production, which deal with the liquid metal.) It turns out that canola oil.

The principle of operation of continuous casting machines are generally simple. The six "streams" are sent to the molds, the passage through which the steel thickens, hardens and takes on the form. For this purpose, it is passed through the copper sleeve of rectangular cross section. Inside they are covered with a thin layer of nickel. Here there is injected periodically and rapeseed oil - the steel is not burnt. It turns the metal on vegetable oil.

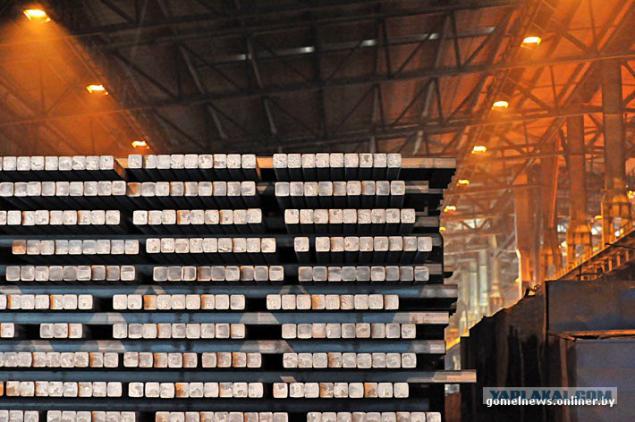

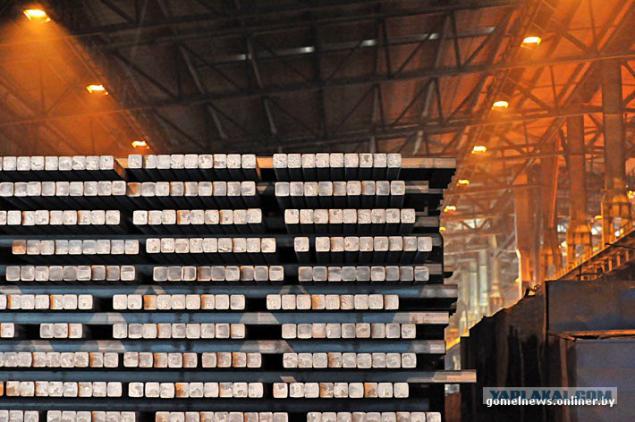

Still red-hot, but has already passed the liquid phase 12-meter beams are sent to cool. Some of them will be sold. But this option metallurgists do not like.

BMZ

BMZ

The fact that the BMZ - the only company in Europe, which operates a full cycle of metallurgical production from scrap to high-tech products such as steel cord. Previously, the plant is actively traded in so-called billets and blooms (the same metal bars, but the larger cross-section - 300 to 400 mm). Partly continue to sell today. In fact, this semi-finished products for further production vyskotehnologichnyh more products with higher added value. The plant is considered that its own semi-finished products processed by the better - so it will be higher profits. Because of this, and proceed by investing heavily in modernization.

Further fate of the workpiece or bloom can develop in different ways. Perhaps its just sell. Maybe - dispose themselves. Harvesting can go to the "road circles" - in fact the core of circular cross-section, used to make parts for cars. Or the pipe. Or rod - wire of different thicknesses and destination. Or steel cord, which with his hands torn manufacturers of automobile tires. Fittings get builders. In particular, it is sent to the Belarusian nuclear power plant.

BMZ

BMZ

BMZ

Red-hot beams, for which we are witnessing, will turn into a wire. So they road in Rolling Mill.

In simplified form, the conversion process of a massive beam into a thin wire looks like multiple rolling through rollers with successively decreasing gap.

BMZ

It looks like these removed in the form of rolls. Round-section alternates with oval:

BMZ

Sometimes in the process of rolling the rod out of control. Then it turns amusing compositions. They were sent to the marriage and to the facility.

Steel thread gets thinner.

BMZ

BMZ

At the end of a 12-meter billet obtained a wonderful bay wire weight 1, 4 tons.

BMZ

BMZ

Today BMZ supplies its products to 55 countries. Perhaps in your Japanese, German, or French car is Žłobin metal. The same applies to the tires - at BMZ buy cord all the major manufacturers.

posledneeee photo. Thank you for attention!

Hello from Belarus)

Source:

Will be 69 photos

Taken from here

BTW metallurgy holidays. Uraaa comrades!

Austrians Italians erected Belarusian Steel Works even when a foreigner, we watched as a miracle. The decision to turn to the capitalist party contractors then looked very exotic. The contract on the construction was signed in 1982, even under Brezhnev, commercial operation officially started in the 85th. Then Zhlobin has focused the best of what there was in the world steel industry. Now BMZ is one of the major domestic exporters and taxpayers. Onliner.by visited one of the hottest, profitable and spectacular productions of the country.

BMZ is now the era of rampant modernization. Dust post: everywhere something to build, break, change. Even skrapovozy scrap sent to the detour: the roads are repaired on site, too.

These heavy machines on wheels made of cast rubber referred to here, of course, "centipedes". They deliver huge "basket" with shredded scrap to the furnace.

2.

Four

5.

The plant, which occupies a territory of about two hundred and fifty acres, operating more than twelve thousand people of Zhlobin and the neighboring settlements.

7.

In the Electric shop №1, where we're going, two ovens, one is working - №2. Shattered space temperature furnace casing №1 piled outside. The furnace was stopped a few days ago - upgrade, going to the October increase its capacity to one million tons of steel a year.

A total of three plant furnace (considering stopped). In general, the company is now the main task - to get to 3 million tons of steel a year. Moreover, BMZ does not want to sell billets, semi-finished products, but more on that below ... Around it all and turns: the radical replacement of equipment, construction of huge plants and the creation of new industries. And it is important to upgrade without stopping production.

At the plant it is necessary to constantly turn my head, listen to the signals to not crept back "centipede", and on top - the crane with a hundred tons of liquid steel. "Danger Zone", it seems, is the most popular label.

The shift meltshop Oleg Pryadko the example of the dismantled furnace №1 simplified describes her device.

Bottom - "hearth" with gutters for discharging metal and slag, above it - the actual body, above - the frame and lid with openings for the electrodes. Inside the container is lined with refractory materials. Outside - hideous hoses and pipes that were in the area unbearable heat. Through them under pressure of 6 atmospheres, is fed continuously to the housing cooling water. Otherwise, he would not survive.

12.

13.

Now the fun begins. Under siren crane delivers a basket with a crowbar. All this falls into the furnace.

16.

Top descend into the oven three powerful "pillars" - electrodes. It uses the simple principle of welding: electric arc melts the metal.

18.

19

20

21.

By the way, in the state of BMZ have pyrotechnics (read - engineers). The fact that scrap - not an easy thing. Especially one that is imported from Russia. In general, the military - a major supplier of iron ingots discharged something unusual at the factory are not. But sometimes the media gets the information about the next batch of ammunition found in the car. There are also some hand grenades and rifle and shots to the RPG and missiles. To all this does not work in the oven and need pyrotechnics.

Furnace capacity - 120 tons. Of these, 110 will merge the rest will flounder at the bottom - metallurgists call it "swamp." Pryadko explained swamp is necessary to maintain the oven in a heated state until next boot. And energy saving, and time.

The electrodes are made of pure graphite. In fact, the three multi-ton pencil leads length 2, 6 m and a diameter of 60 cm.

23

We watch the process from behind the glass control panel. On one of the monitors, among many obscure characters flit numbers - the number of kilowatt-hours consumed.

Oleg Pryadko said that in the one melting furnace burns 42,000 kVt.-hour of energy - can be a day to feed the city with a population of 80,000 (as of Zhlobin).

Heating is provided not only by the electric arc, but also due to the combustion injected into the carbon, oxygen and other components.

Controllers (joysticks) can be controlled from the control different processes. Including tilt the oven to "shake up" the contents for more uniform heat.

26

27

In the most extreme places are air-cooled camera, a picture with them and displayed on monitors. Actually, there is a particular dynamic to be seen - just the flames of hell. They say that if "dynamics" - then something went wrong.

On the lookout more beautiful and much hotter. The liquid steel through the filter resembles a boiling soup with protein foam. Near long idle time - was hot. On the addition of alloying elements and other provisions of the melt additive technology responds beautiful waves of multicolored flame.

The melt temperature of about 1650 degrees. Since this figure to the uninitiated nothing says steelworkers of the Soviet Union, loving visibility lead invariable example: that if to throw a cat in a bucket, do not fly to the liquid metal evaporates along the way. Cats, of course, there's spawn was not found, but somehow believe in the word.

31

Melting takes about 50 minutes. After that, the metal fuses (do not forget to leave the "swamp"). The slag is separated - it will be sold to builders.

Before you get on steel casting machine, it must be "Dowar" in the ladle furnace to "slow fire" - about 1,550 degrees.

33

In the process of finishing the sample is taken. Also the whole affair. Operators loved old movies to shoot the epic steelworker who long ladle scooped in Martin sparkling mass. Now, there is no beauty that ... invented a special one-off tube of pressed paper. It is attached to a metal rod, is dipped into the metal, and then pull out, pull out quickly hardening "probe."

He also

In a similar way to measure the temperature of the melt - by connecting to an external indicator paper the tube, which is hidden from the thermocouple wires of platinum and rhenium.

Ready liquid enters the continuous casting machine №2. She, by the way, living out the last days of date. The shop has already cleared space for new equipment.

Near the refractory practiced with remote imposing. Instead, radio-controlled cars they tracked machine with a manipulator. At its end is mounted jackhammer. Learn a new technique: knock petrified protective lining (lining) from the bucket in front of repair.

36

37

38

39

By the way, about the refractory. This is one of the most heroic profession. Its essence is to prepare a huge bucket to fill in a metal. Generally, the liquid steel is easy to cut the metal walls. Probably every steel plant is a legend about how the day went bankrupt bucket. In such cases, a white jet of pressurized peel wherever falling. To avoid this, the inside scoop spread in several layers of refractory bricks and / or coated with special cement. After 60-65 heats all knock - and the new ...

There are 6 casting machine workers - the number of streams of liquid steel, which do not have the right to be interrupted. The slag from the surface of the liquid metal is removed manually with iron hooks. Soon this technology will go into oblivion.

BMZ

BMZ

BMZ

BMZ

BMZ

Beauty

where do without pets

BMZ

In the air, a strange smell, as if something in the pan burnt (and it is not blue). (As strange as it sounds for the production, which deal with the liquid metal.) It turns out that canola oil.

The principle of operation of continuous casting machines are generally simple. The six "streams" are sent to the molds, the passage through which the steel thickens, hardens and takes on the form. For this purpose, it is passed through the copper sleeve of rectangular cross section. Inside they are covered with a thin layer of nickel. Here there is injected periodically and rapeseed oil - the steel is not burnt. It turns the metal on vegetable oil.

Still red-hot, but has already passed the liquid phase 12-meter beams are sent to cool. Some of them will be sold. But this option metallurgists do not like.

BMZ

BMZ

The fact that the BMZ - the only company in Europe, which operates a full cycle of metallurgical production from scrap to high-tech products such as steel cord. Previously, the plant is actively traded in so-called billets and blooms (the same metal bars, but the larger cross-section - 300 to 400 mm). Partly continue to sell today. In fact, this semi-finished products for further production vyskotehnologichnyh more products with higher added value. The plant is considered that its own semi-finished products processed by the better - so it will be higher profits. Because of this, and proceed by investing heavily in modernization.

Further fate of the workpiece or bloom can develop in different ways. Perhaps its just sell. Maybe - dispose themselves. Harvesting can go to the "road circles" - in fact the core of circular cross-section, used to make parts for cars. Or the pipe. Or rod - wire of different thicknesses and destination. Or steel cord, which with his hands torn manufacturers of automobile tires. Fittings get builders. In particular, it is sent to the Belarusian nuclear power plant.

BMZ

BMZ

BMZ

Red-hot beams, for which we are witnessing, will turn into a wire. So they road in Rolling Mill.

In simplified form, the conversion process of a massive beam into a thin wire looks like multiple rolling through rollers with successively decreasing gap.

BMZ

It looks like these removed in the form of rolls. Round-section alternates with oval:

BMZ

Sometimes in the process of rolling the rod out of control. Then it turns amusing compositions. They were sent to the marriage and to the facility.

Steel thread gets thinner.

BMZ

BMZ

At the end of a 12-meter billet obtained a wonderful bay wire weight 1, 4 tons.

BMZ

BMZ

Today BMZ supplies its products to 55 countries. Perhaps in your Japanese, German, or French car is Žłobin metal. The same applies to the tires - at BMZ buy cord all the major manufacturers.

posledneeee photo. Thank you for attention!

Hello from Belarus)

Source: